Hardware (metal, rubber, etc.).

Screws, nuts, bolts, bearings, locking methods for hardware.

Discussion of Pozi, Reed & Prince, Frearson, & Phillips screws.

Items & references not found in references page (78A):

https://bmwmotorcycletech.info/references.htm

©

Copyright 2021, R. Fleischerhttps://bmwmotorcycletech.info/hardware.htm

68A

General notes on parts:

BMW has used two methods over the years to code parts. This is applicable to fiche, CD's, and other literature. A list of these codes is in article 69: https://bmwmotorcycletech.info/partsymbols.htm

Stainless Steel: Many folks have purchased stainless steel nuts, bolts, etc., which are available individually, but also in pre-packaged sets for your bike. STRONGLY CONSIDER USING AN ANTISEIZE COMPOUND ON THEIR THREADS. Failure to do so MAY result in eventual GALLING, a form of WELDING, or, a type of corrosion. In some instances you may want to DEcrease the torque value a bit. In general, common SS parts are not as strong as regular steel (whether cadmium plated or otherwise treated, ...or not, by BMW) stock parts. Be especially cautious where original parts were specified/graded 10.9 or higher. Be exceptionally cautious about substituting wheel bolts on the Monolever and Paralever models. As somewhat of a side note here, cadmium-plated-steel parts have mostly disappeared, due to modern Euro-specs. You probably have noted that I have not included any specific list of SS substitutions and other cautions, per each item, in this article. You may want to review the Locking Methods section of this article (that is the last section).This article lists & describes, hardware items for BMW Airhead motorcycles & may have errors. It was not possible to physically inspect every part listed here. Parts numbers & descriptions were taken from a Snabb Katalog & checked against a 1995 printed Parts List (the last such ever printed on paper by BMW). Most were checked against my own stock of parts; some were checked against on-line fiche. A small amount of input was from others.

BMW on-line fiche is not as fully descriptive as some other types of BMW parts literature. Most of you will use only the on-line fiche, which is generally adequate-enough. Here is a good source of such on-line fiche: https://shop.maxbmw.com/fiche/PartsFiche.aspx

Be sure you understand that what shows in such literature is either the original & still valid part number, or an updated part number (which could be the exact same original part); or, in many instances, the part is an updated or later part that BMW says can substitute for the original part. Note that just because one part is so shown, does not mean that you might ...or might not... have to replace other associated parts. A common example are the parts at the throttle cable gears and cam assembly, and perhaps also the master cylinder. There may be a transition date listed, that can be quite informative, if it is accurate. Don't take the dating information to always mean the original transition date.

BMW descriptions in its literature are sometimes wrong! In illustrations or sketches, BMW may rather often show a piece of hardware ...or other item ...that is not the actual part. An mild example: an actual Allen bolt is shown in the illustration as a screw or hex head. Especially be aware that BMW sketches (often the same or similar sketches are found in Clymers and Haynes manuals), can be VERY misleading on order of assembly, and VERY misleading as to whether...or not!... such a part is actually used on YOUR motorcycle. This is very particularly true in one critical area, the illustrations showing all the various parts for a particular assembly of the oil filter canister area. Same, but not as critical, for the front forks internals. DO NOT think that ALL those parts will necessarily be, or should be, in YOUR bike. Clymers & Haynes have messed this up even further!

BMW may call some parts by names that, in translating their German to our English, do not mean the same thing; this is especially egregious with the names of bolt & screw head styles.

BMW sometimes kept the same part number after making changes to the part. In most instances this is of no major concern. In many instances the updated part is better for some reason or other. Sometimes there are problems. Here is an example: BMW changed some of its nut & bolt head sizes. The same part number is being used for a nut that originally needed a 19 mm wrench, & the newer shipped parts are for 18 mm wrench, a size of wrench that is not standard for BMW Airhead motorcycles, but is for other BMW bikes. Unless you want to obtain and carry the non-standard wrench in your bike's tool tray, you should be aware of this. In many instances, the dealer will have both sizes available in the same box, as the part number was the same. I do NOT know the full extent of this problem. I have seen it in 16 mm heads too. My advice is to check the bolt or nut before you purchase or order from dealer stock.

ONE of the many purposes of this article is to enable you to go to a dealer & hopefully see the various parts, & then decide what you want.

Bolt length measurements are always taken from under the head to the end of the threads. BMW bolts used to be cadmium plated to prevent rusting and that plating also provided some slight anti-seize protection, and more consistent tightening. BMW has discontinued cadmium plating due to European environmental regulations. Many steel bolts & nuts now will rust! Some may now have zinc or other coatings or such as phosphates treatment. In my opinion those are not as good as the original cadmium plated items.

I am NOT saying to willy-nilly coat all nuts, bolts, screws, etc., with antiseize compound. You must judge where/when; perhaps consult the Airheads LIST and/or this website. Use of anti-seize compounds generally requires the torque wrench to be set a bit lower.

In a very few instances you must NEVER use any added coating & that includes oil, grease, or anti-seize. One such instance is the rear wheel bolts on the Monolever & Paralever models.BMW generally uses bolts rated at 8.8 strength, but at certain places will use stronger; even as strong as 12.9. Strength rating is always marked on the bolt heads ...and on some smaller screws too. Beware of using aftermarket stainless steel parts!

(1) Ever wonder what the number on the end of a metric bolt really means? You already know it has to do with the strength of the bolt. What does it really mean? Here is your answer:

The strength is shown by this format: X.Y. Thus, 10.9 or 8.8, etc.

The X number is 1/100th of the tensile strength in newtons per square mm.

The Y number is 10 times the ratio between YIELD and TENSILE strength.

Example (and the math done for you here) for the very common 8.8 rated bolt:

The X is the first 8. That means the tensile strength of the bolt is 800 newtons/mm˛. For your information, so YOU don't need to do the math: that means 116,000 psi.

The Y is the second 8. That means the yield strength of the bolt is 640 newtons/mm˛. For your information, that means 93,000 psi.

No, not going to tell you how those numbers came about; nor, how I calculated the PSI; ...YOU get to research that, if curious enough!

(2) The waverly washers used by BMW may, in some circumstances, provide LESS holding power for the bolt/nut than NO waverly washer. Very complex to understand, has to do with the surfaces sliding in relationship to each other, which not only loosens them, but tends to UNSCREW them .....and; it was a German company that did the testing that proved all this. There is a discussion of locking methods, at the bottom area of this article, see: Discussion of 'locking' methods for hardware.An article about threads and fasteners, that is relatively easy to understand, and explains things in depth, yet simply: http://gmcws.org/blog/wp-content/uploads/jim-rowe-fastener-presentation.pdf

Some BMW bolts have a non-standard HEAD THICKNESS. An example of this will be seen at the left lower rear shock mount on twin rear shock Airheads.

The word 'screw' & the word 'bolt' are sometimes used interchangeably. Typically screw means smaller diameter, but there is no specification for just what constitutes smaller. Although there is some confusion sometimes between what is a screw & what is a bolt, in almost all instances "screw" is used for those parts that have Phillips or similar look heads; single slot heads; small screws with such as Torx and many other heads, including allen-heads. It can be confusing, because 'bolts' are generally described as being used with a nut; but quite small screws used with nuts are NOT called bolts. Konfuzed? ...well, here is a bit more, which might (?) clarify things a bit:

"Bolt" is just about universally used with hex-head items, & either bolt or screw can be used with some types of parts. BOLT used to, long ago, be used when the head of the bolt was either a 6 flat hex or a square, although BOLT was sometimes used for such as Carriage Bolt, which has a domed head with a square UNDER the head, said square fits into a corresponding female hole in the material to be clamped. My advice is to simply call threaded fasteners that are under ~1/4" in shank diameter, SCREWS; and, larger ones are BOLTS.

Part numbers on a part MAY NOT BE BMW ordering numbers (numbers found on electrics often are BOSCH numbers or Wehrle numbers, but sometimes BMW numbers are found there too). Numbers may be partial, that is, abbreviated, and this is common for both BMW and other makers, such as Bosch. All these things apply to mechanical parts, not hardly just electrical parts. Numbers on assemblies ...or any part ...may NOT be the same as the BMW order number. The number on a part might be some non-BMW number; or, a BMW part-assembly or casting number, whether it is a casting or not. This also applies to machined items. If you cannot get a reference to the number from one of the on-line parts listings like A & S, MaxBMW, etc., you MIGHT have that situation. Ask on the Airheads LIST if you cannot figure it out yourself ...many of us are quite familiar with various part numbering's.

PLEASE point out errors found in this article to the author, E-mailing to the address found here:

https://bmwmotorcycletech.info/emailimage.htm

Abbreviations:

BL MU sheet nut BMW may list them as BL MU 4, 2-4; also listed as B4, 2-4 BLMU ...these are all the same thing. These are sometimes generically called Tinnerman nuts in the USA. They are a folded piece of metal, that are used with fairing parts, to provide a place for a screw to go through one side & tighten on the other side. There are many types of these used on aircraft, musician's electronics chassis, etc. Some expensive types have a hardened metal nut that floats in a cage, that works exceptionally well. Modest cost ones work fairly well on the BMW fairings ...but I do not like the cheapest of the cheap. I have the part numbers in the miscl. area, well below.

BL SHR sheet metal screw. NOTE this: 6KT BL SHR hex lens head screw

DT RG gasket ring

KL Generally used for the type of C (or E) clip used at the seat holding pegs.

LIN BL SHR fillister head self tapping screw

LIN SHR fillister head screw (see note below)

LIN SK BL SHR countersunk head fillister self-tapping screw

LIN SK SHR countersunk head fillister screw

MU nut

PA SHB disc ring

SHR screw (see note below) Schraube

SK BL SHR countersunk lens head screw

SK SHR countersunk head screw

STI SHR studbolt

VSL SHR plug screw

ZNS zinc sulphide treated

ZYL SHR fillister head screw (fillister per BMW's description but is an allen head bolt) .... well, mostly, ...and sometimes another type! See **** just below for a further explanation. ZYL-SHR is zylinderschraube; compare the American use of "cheese-head screw".

6KT SHR hex screw -KT-SHR is really a hex head, although the SH might lead you to believe it is a allen type. HB is supposedly a hex head bolt only.

ZYL STI dowel pin

4KT MU square nut

6KT MU hex nut

****BMW may use the word 'fillister', in its translations to English, differently than in common American usage. In America, a fillister-head screw is NOT an allen head screw; but BMW's usage MAY mean allen-head, that is, a recessed 6 point socket for use with an allen wrench. BMW may use socket head, correctly, for an Allen Headed screw. There is further confusion with PANHEAD & CHEESEHEAD screws.

I will try to explain a little of this confusion that you may sometimes see. Zylinderschraube may be shown in literature as ZYL SHR. A TRUE fillister head, in German, is a LINsenschraube, which you will see as a LIN identification. Could be LIN SHR. There is further confusion in that ZYl SCHR has been used in some literature. It is all a MESS! Generally speaking, a taper under the head type screw is called LIN SK SHR by BMW. Some of the confusion is due to old translations by BMW or whoever did the old SNABB Katalogs and other literature. Sometimes the confusion is that BMW has used more than one type of head on a fastener at any given place, that is, changed it over time, & the description might have a new part number, & the descriptive words were never changed, & might not have been correct in the first place. BMW often does not show the actual type of part in BMW sketches.

I still have NOT seen the proper description for an Allen headed screw in BMW literature. Innensechskantschraube or inbussschraube.

BMW has sometimes substituted various types of heads; you might order one type & get another type, and shipments have been like that to all sorts of various countries, not just to America!

Yes...all this is very confusing! If you have a question, ask on the Airheads List.

I have tried to separate out the confusion, in the parts listings below.

When using on-line "fiche" from such as Maxbmwmotorcycles, etc., do NOT use hyphens nor spaces between the numerals. Simply remove them so the part number has no spaces nor hyphens. Do NOT replace hyphens with spaces. While that MIGHT work fine, in some instances it does not.

Many older part numbers are no longer listed in on-line fiche. I can usually identify such parts for you, as I have parts catalogs going back many decades.

Hex nuts:

07-11-9-922-053; -054. M-6. Some books show a locking nut; other books show this number being replaced by 23-11-2-322-368.

07-11-9-922-081; -856; 07-11-9-921-076; -077; -074. M-8. Some books have the -074 and -081 as locking types; the -081 is replaced now by 07-11-9-922-825, and THAT by -856.

07-11-9-922-110; 11-11-0-001-104, replaced by 11-11-1-263-903. M-10. Some books show -110 as locking, the -110 is replaced by 07-11-9-915-558.

07-11-9-922-122. M-10 x 1.0 mm.

33-17-1-237-789. M-10, 12 point.

07-11-9-922-148; -940. M-12 x 1.5 NOTE: may be 18 or 19 wrench size.

07-11-9-921-631; -633; 07-11-9-901-309. M-14 x 1.5

Security nuts:

These are similar to Nylocks; that is, they have plastic inserts. BMW also has used other types of security nuts, some are here. Sometimes BMW will identify a nut as a security type ....maybe it is, maybe it is not! Do NOT depend on the numbers here to be security nuts, without looking at one! Some of these numbers may be no longer available, or, just wrong now.

07-12-9-922-404; -452. M-4.

07-12-9-922-411; -410; 07-11-9-922-035; 12-31-2-322-422; 07-11-9-921-038. M-5.

07-12-9-922-416; -417; -800; -807 ; -704. M-6.

07-11(and 12)-9-922-053. M-6. Some books show this as a locking nut; other books show this number being replaced by 23-11-2-322-368.

07-12-9-922-428; -427; -713; 07-12-9-964-675; -716; -087; -096; 18-11-4-090-251. 6KT MU M-8.

07-12-9-922-435; -434. M-10. Self locking.

07-11-9-921-615; 07-11-9-900-079. M-10 x 1.

07-11-9-922-148; -940; 07-11-9-921-627. M12 x 1.5.

07-11-9-921-069; 07-11-9-901-307. M 16 x 1.5.

Cap nuts (sometimes called closed dome nuts):

07-11-9-924-000 M-5

46-61-1-236-388; 07-11-9-924-403 M6

07-11-9-924-324 M-6

07-11-9-924-334 M-8

11-12-0-023-160; 11-12-1-744-330 for center of valve cover

Lock & wave (spring) washers. BMW has interchanged these at times per #, & I believe that sometimes BMW is not accurate on what type is which, as far as waverly, plain, locking:

07-11-9-932-009 A-3.

07-11-9-932-013 B 3.

07-11-9-932-030; -033 B-4 waverly. 'dented' washer is 07-11-9-936-041.

07-11-9-936-042 J 4,3 STAR washer.

07-11-9-932-041; -043 A-5 -041 replaced by -098; -043 by -047.

07-11-9-932-079; 07-11-9-933-095 A-8.

07-11-9-932-046 B-5 lock (spring washer, 5 x 11).

07-11-9-932-062; -061; -070; -071; -072; #6 or B-6.

07-11-9-932-073 WAVERLY B6.

07-11-9-933-082 B6 lockwasher.

07-11-9-932-093; -077 both are B-8 spring waverly.

07-11-9-933-095 SS split lockwasher, was replaced by 07-11-9-904-115

B8 wave washer.

07-11-9-932-112 B-10 spring; may be A; large O.D.; for medium diameter A-10 use -103 and -111; for large O.D. A10 use -122. See also 07-11-1- 242-296.

07-11-9-933-110 B-10 lock.

07-11-9-936-042 J type 4,3 star washer.

21-21-1-242-377 A 7,4 star washer (BMW calls it a fan washer); clutch washers.

07-11-9-936-191 A 8,2 star washer.

07-11-9-930-840 B8 SPLIT lockwasher. This is the washer that was

used at the driveshaft U-joint before BMW wised up & eliminated it in favor of a slightly shorter bolt.

34-11-1-240-570 flat size 8 washer.

Plain washers:

07-11-9-931-029 black.Plain (solid) sealing washers & crush washers:

Note: many early crush type washers are now being shipped as slightly different number and are solid types. This has happened with both aluminum and copper types.

For the -097 neutral switch at the bottom of the 5 speed transmission you must use ONE special washer, which is 61-31-1-355-262, shown in the fiche as A12,2 x 20 AL. DO NOT use a common drain plug gasket washer. Reports of BMW shipping the wrong washer have been seen. Tom Cutter measured a new one & it was 19.8 mm x 12.35 mm x 1.89 mm. Original new ones, which might fit better (?) are probably 2.0 mm thick. It is best to use a new washer, but sometimes the old one will seal adequately.

07-11-9-963-140 DT RG C 12 x 15.5 crush, driveshaft drain and driveshaft fill.

07-11-9-963-999; -470; -047; -041; DT RG C (or A) 8 x 11.5 Fork drain, late model rear drive oil level inspection hole.

07-11-9-963-213; -200 14 x 20 DT RG rear drive drain; transmission fill and drain.

07-11-9-963-259; -200 oversize 16 x 20 DT RG rear drive drain; transmission fill and drain.

07-11-9-963-252 DT RG A 16 x 20 used at pulse air fitting at cylinder head and at the airbox.

07-11-9-963-073 10 x 13.5 x 1 solid washer for top of fork bolt.

07-11-9-931-622; -015 3.2

13-11-1-259-870 3.5 mm hole washer used on the Bing carburetor vacuum port screw.

07-11-9-936-413; -412; 07-11-9-931-637 A4 flat washer, 4.3

07-11-9-936-415; -416 5.3

07-11-9-963-010 DT RG A 5 x 7.5 small solid washer, fork drain.

07-11-9-963-034 solid washer, thermostat lower bolt 6.5 x 9.5.

16-11-1-232-237 plastic washer that fits 4 mm screws.

07-11-9-963-310; -300 DT RG C 18 x 22 crush, engine oil pan drain. -300 is solid washer.

07-11-9-963-002 flat washer 3.5 x 6

07-11-9-963-420 DT RG 26 x 31 used at dipsticks until 1980. Part is obsolete, but UNconfirmed information was that POSSIBLY #11-43-1-337-308 will work.

Here is further information on possible washers for the banjo bolts used at the oil filter cover:

07-11-9-963-151, A12 x 17-cu These 12 mm washers are copper. Note the 17 mm outer diameter. Also used at fork bottom.

07-11-9-963-132, A12 x 16-cu These are copper. Note the 16 mm outer diameter.

11-42-1-338-783 R100R and the GS models, I don't have the exact measurements, seem to remember they were copper.

07-11-9-963-130 DT RG A 12 x 15.5 (or 15.0) solid aluminum sealing washer for oil cooler banjo bolt; also neutral switch on early 5 speed transmissions. see also 61-21-1-355-262, and at fork lower, bottom, center bolt. Copper washers are better, and safer, but BMW is no longer providing them. Get 25 for less than a dozen bucks, at McMaster-Carr under part number 97725a250...they are M12, yes, copper, and 12.2 x 15.9 x ~1.5.

M-4 hex head bolts, 4KT SHR:

07-11-9-913-091 4 x 20

07-11-9-913-097 4 x 25

M-5 hex head bolts, 5KT SHR:

07-11-9-913-212 5 x 8

07-11-9-913-218 5 x 10

07-11-9-919-613 5 x 12

07-11-9-919-903; 07-11-9-913-252 5 x 20

M-6 hex head bolts, 6KT SHR:

07-11-9-913-426; -432; 07-11-9-914-148 6 x 10M-8 hex head bolts, 8KT SHR:

07-11-9-911-605; 07-11-9-910-342 8 x 12 thread pitch 1.0

07-11-9-913-618; -624; 07-11-9-901-191; 07-11-9-919-939 8 x 16

07-11-9-913-640; 07-11-9-901-120 8 x 20

07-11-9-913-652 8 x 22

07-11-9-913-656; 07-11-9-901-125 M8 x 25

63-12-1-356-921 8 x 25 as used on side of /5 headlight shell

07-11-9-913-662 8 x 30

07-11-9-913-111; -674; 07-11-9-912-477; 33-41-1-232-701 M8 x 35

07-11-9-912-507 8 x 45

07-11-9-918-655 8 x 50

07-11-9-912-556 8 x 80

46-51-1-234-785 black plastic cover for hex head of M8 bolts.

M-10 hex head bolts, 10KT SHR:

07-11-9-911-631 10 x 1 x 20 as used with /5/6 oil filter inner cap

M10 and M11 special flywheel bolts are not shown in this area

12 mm hex head bolts:

none I know of at this time

14 mm hex head bolts:

none I know of at this time

4 mm Allen bolts ZYL SHR:

07-11-9-919-381 4 x 125 mm Allen bolts ZYL SHR:

07-11-9-919-611; 12-13-2-322-416 5 x 8

07-11-9-919-614; 07-11-9-900-311 M5 x 16

07-11-9-919-617; -903; 12-31-2-322-418 5 x 20

07-11-9-919-619 5 x 30

07-11-9-919-908; 12-31-2-322-417 5 x 45

07-11-9-919-910 6 x 10

07-11-9-919-792 M6 x 10, with captive waverly

07-11-9-919-912 6 x 12

07-11-9-919-621; -965; -913; -912 6 x 16

07-11-9-919-918; 46-54-2-322-498 M6 x 18

07-11-9-919-716; -920; 23-11-2-322-407 6 x 20 The -407 usually has a deep head which is particularly nice for use at the oil filter outer cover/housing.

07-11-9-919-921; 46-71-2-322-405; 07-11-9-919-625 M6 x 25

07-11-9-919-927; 31-42-2-311-105 6 x 30

07-11-9-919-931; -932 M6 x 35

07-11-9-919-937; 46-61-2-322-494 6 x 40

07-11-9-919-630 6 x 50

07-11-9-919-956; 61-12-2-322-496 6 x 60

8 mm Allen bolts ZYL SHR:

07-11-9-919-637; 8 x 12

07-11-9-901-023, replaced by 07-11-9-904-101; 07-11-9-919-939, repl. by

07-11-9-903-984. All 8 x 16; 8.8 grade, zinc treated

07-11-9-919-969; 8 x 20 8.8 rated, zinc plated

07-11-9-919-646; 07-11-9-901-024 8 x 25

07-11-9-919-647; 07-11-9-901-025 8 x 30

07-11-9-919-984; 07-11-9-901-027 (zinc plated) both are 8 x 35

07-11-9-919-648; 07-11-9-901-029 8 x 40

07-11-9-919-638; 07-11-9-901-033 8 x 45

07-11-9-919-649; -796; -803; 07-11-9-901-034 8 x 50

07-11-9-919-651 8 x 55

07-11-9-919-656; 07-11-9-901-036 8 x 80

10 mm Allen bolts:

07-11-9-919-662 M10 x 12

07-11-9-919-787; 07-11-9-901-039 10 x 20

07-11-9-919-769; 07-11-9-901-049 10 x 30

07-11-9-919-740; -771; 07-11-9-901-064 10 x 35

07-11-9-919-756; 10 x 60

07-11-9-919-672; 33-17-1-454-309; 07-11-9-901-088 10 x 45

07-11-9-919-739 10 x 50

12 mm Allen bolts ZYL SHR:

Described as a "fillister head"; as BMW calls it in their translation; but this is actually an allen head bolt, and it is a totally different head than the American slotted head which Americans call a fillister.

07-11-9-901-116; M12 x 40, rated 8.8, and is a ZNS (zinc sulphide treated).

07-11-9-919-766; M12 x 30. Superceded by 07-11-9-919-778. The -778 was generally used on the later fork style where the lowers contained the oil drain screw on the SIDE, not bottom area as earlier. This was not universally true for the -778.

14 mm Allen bolts:

none I know of at this time

Threaded lengths, studs:

07-11-9-908-255 STI SHR 6 x 25.

07-11-9-908-104 STI SHR 6 x 40. No longer listed in fiche. Now BMW ships 07-12-9-904-546.

11-11-1-252-310 STI SHR length?? Size? used at front of engine-to-timing chest

07-11-9-903-306 STI SHR 8 x 18

07-12-9-903-326 STI SHR 8 x 25 SS

07-11-9-903-349; 07-12-9-908-130 STI SHR M8 x 35

neither number presently in the fiche.

07-12-9-908-141 STI SHR 8 x 45 no longer in fiche.

07-12-9-908-135 STI SHR M8 x 50; replaced by 07-12-9-901-917 M8 x 50, ZNS

07-12-9-908-137 STI SHR 8 x 55

07-12-9-908-145 STI SHR 8 x 65 mm ...the original valve cover center stud. No longer in fiche.

07-12-9-908-142, STI SHR 8 x 70 mm ...longer version of the valve cover center stud.

07-11-9-908-385; STI SHR M 10 x 35 SN 4

no longer in the fiche.

07-11-9-903-436 M10 x 35-PHR.

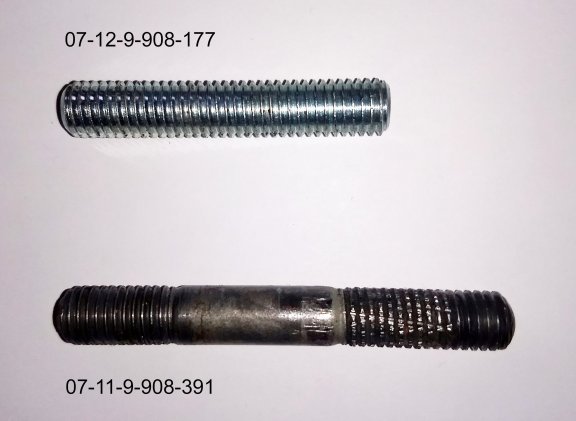

07-11-9-908-391 A no longer available part number; replaced by 07-12-9-908-177 which is shown in the BMW literature simply as M10 x 55. I do NOT like an all-threaded part being used here! The stud is used at the rear drive for the shock absorber mounting, /5 to at least into the eighties. A very strong rating is a must for this part. I suspect it is specified at 10.9 (??). I have not had a chance to remove various ones from assorted rear drives for measuring and testing, but someone else has furnished me with the photo, just below. From what has been reported to me by someone else, the proper part is likely a DIN 835 M10 x 55; a special stud specification. That person measured his stud at 20 mm long on the end that fits into the rear drive. The nut end is 26 mm. The length of the nut end and the unthreaded portion was 55mm. The overall length was 75 mm. That length does not correspond to any of BMW's literature; and, note, that the -391, in SOME literature is said to be 35 mm long. I suspect the confusion is over the -177 which was the shorter length, or, mixed up at BMW for the numbered baggies. This is not a common hardware store stud item. This type of stud is mandatory for such a high stress position. Use heat when trying to remove one. May be: Din 835 M10 x 55, available from www.metricmcc.com; but their strength rating seems low. Metric & Multistandard Components Corp. Note that a bushing is used over the studs, see any BMW dealership parts fiche; and, note that having all threads, bushing or not, is a BAD idea. If a stud breaks, it is much more likely to break at a point of stress and sharpness, and that is at a thread. A proper stud has a smooth, no threads area, and the threads are very carefully made and relieved at the end of the threads where they meet the non-threaded area. DO NOT use a low strength threaded item for a shock mounting stud/bolt. In order to remove one of these studs, they are usually installed using a high strength Loctite, and you will need a lot of heat. The lower stud in the photo has slightly mangled threads from the removal process that was used.

11-11-1-257-397 275 mm cylinder stud, M10 x 1.5 mm.

11-11-1-265-195 297 mm cylinder stud; used at right side, rear, both, 10 x 1.5 mm. This longer cylinder stud is used on the RIGHT side cylinder, top and bottom rear.

46-71-1-230-762 Threaded at both ends stud used at footrest & engine mounting. M12 x 1.5 x 306 mm.

46-71-2-311-725 same, engine mount stud, but 315 mm long.

46-71-1-230-475 same, engine mount stud, but 327 mm long.

Common (??) screws, can be slotted or phillips, even if codes say the item is another type:

07-11-9-907-701 special self-tapping screw used at fairing vents, really a size 3, but some books says B2.9 x 6.5; others will show this screw as ST2,9X6,5

07-11-9-928-432; -130; -103 M4 x 16 SK SHR, screw used at fairing vents.

07-11-9-907-603 3 x 10 LIN SHR see next line.

07-11-9-907-602 LIN SHR AM 3 x 8 screw used at one style of crankcase oil breather; NOTE: book shows -602 to be used for -603.

NOTE that BMW literature has been inconsistent on the -603 and -602 screw.

Latest fiche shows the screw as a REAL fillister head (with phillips type drive)

and as M3 x 8.

07-11-9-907-604 LIN SHR AM 3 x 10.

07-11-9-907-616 LIN SHR AM 4 x 10.

07-11-9-906-435 LIN SHR 4 X 12.

07-11-9-913-373 4 x 10 ZYL SHR AM.

07-11-9-919-381 4 x 12 ZYL SHR AM.

07-11-9-901-703 4 x 12 LIN SK SHR.

07-11-9-901-720; 07-11-9-928-439 SHR AM 4 x 20 phillips.

07-11-9-907-639 LIN SHR 5 x 10 used at seat side rail.

07-11-9-907-627 LIN SHR AM 5 x 12.

07-11-9-901-771 5 x 15 LIN SK SHR AM.

07-11-9-906-415 SHR AM 5 x 16.

07-11-9-928-485; -487; -488 5 x 15 LIN SK SHR M replacements are 5 x 20.

07-11-9-901-771 LIN SK SHR 5 x 15 used at the seat strap.

07-11-9-907-631; -633 5 x 20 LIN SHR AM.

07-11-9-900-810 SK SHR M 6 X 10 counter sunk allen head used at seat hinge.

46-63-1-236-414 SHR M6 x 30.

Miscl. hardware "and things"... (that I am too lazy to find a section or area for):

If the flywheel has a groove (and it will if it is 10/1975 or later), it needs an o-ring there. It was 11-22-1-337-099, now is -093. A long time ago the number was 11-22-1-263-798. The O-ring is called a Seal Ring by BMW. It is 59 mm x 3 mm.

The flywheel bolts are special. The /5 and early /6 bolts (before 09/1975) were 11-22-0-016-759 and M10 x 1 pitch and 24 mm long; and I believe they should always be replaced if the old ones are ever removed. Afterwards, the bolts have a different number (see fiche for latest number) and are 11 mm with 1.5 pitch, and are 32 mm long. These are much stronger, use a much higher torque, and I seldom have to replace them with new ones.

51-14-4-034-136: This is the frame ID metal plate, comes flat, you must curve it. It fits the steering head area, is designed to be riveted in place. These are NOT obtainable from BMW, AFAIK. Bob's BMW has them, and likely some others. You have to stamp in your model, serial, etc.

Fairing pocket rubber channel material fits between fairing pockets and the fairing. Many have substituted part 05-01300 #1 Rubber Channel; from www.aircraftspruce.com/catalog/appages/uchannel.php. It has a 1/16" groove and is 3/4" high. Can also be used at the pockets themselves, where the covers fit.

Fairing pocket COVERS:

These use solid, soft, round rubber strips that many folks install with cyanoacrylic cement (Crazy Glue, etc). That 'glue' tends to crack and allow the rubber to come loose. Many times this rubber is not thick enough for one's particular covers & fairing pockets, & there are water leaks, rattles, etc. If you go to Lowe's, or Home Depot, etc., you can find, quite cheaply (compared to BMW price for the two small strips) 'gasket' material, made of a rubber compound, and it has a splined-look. It is found in the area of the store that has screen doors & hardware for screen doors. Smallest package I've seen is 25 feet, for a few dollars. I have seen this stuff in various sizes, from 0.110" thick to 0.175" thick. I use Elmers Probond to install it, using very light clamping pressure. It dries quickly enough, but not spectacularly quickly. After it dries overnight, I apply a second dab here and there to be sure the adhesion is very strong. If you insist on it, the stock gasketing material from BMW is 46-63-1-239-586, one piece, 485 mm in length.

Rubber seal-strip (or rubber O-ring, whatever you want to call it), located in the PRE-1979 timing chest, in a groove surrounding the points cavity:

This has multiple part numbers in the various fiche over the years. The situation is confusing. The BMW material comes in short strips, and in much longer pieces. You really should find out which rubber piece will properly fit, as the grooves vary, and so does the rubber material! Install a precisely cut length after cleaning the cavity groove and the rubber with acetone. The most common recommendation is to put small droplets of cyano-acrylic glue (Crazy Glue, etc.) in the cavity groove, before installing the rubber piece. Push a few times into position if need-be. Cut with an Xacto knife to fit; let sit overnight. The next day, CLEAN lightly several times with acetone on a rag, to get any excess glue removed. I recommend against what some others have, which is to rub with a bar of soap as the next step after the acetone cleaning. I smear a VERY SMALL amount of silicone dielectric grease on the surface, using my finger, before replacing the outer cover, no matter what glue, etc., I used. 11-14-1-265-394 is supposedly 3.2 mm, used until 1974, approximately. However, some fiche imply to 1975. Thereafter, and some fiche say for 1976 to 1978, you are to use 11-14-1-262-644 ....supposedly, in some fiche, 4.2 mm, some fiche say to use after 1974. Awhile back, if you were to order either, you would probably will get the -394 size. Maybe.

HINT! You can use a Classic K bike oil filter cover O-ring, which is 11-13-1-460-425, even a used one! Thanks to Tom Cutter, for this hint! Added by me, is that this K bike O-ring is 88 mm x 3 mm in size, and is used on the Classic K bikes which are K1, K75, K100, K1100 ...at the oil filter outer cover. This O-ring is also used at various places in such as a R1200GS, and K1200. You need to check the particular groove in your Airhead, see what fits, then clean that groove and clean the O-ring, and install with the Crazy Glue (or, similar). You can, instead of a cyanoacrylic (Crazy Glue, etc.), use any good quick drying rubber cement in the groove, then press-in the rubber. Wait overnight, then clean surfaces lightly with acetone, add a faint smear of silicone grease, and install the outer cover. Watch the installation carefully ...there is a rubber grommet which has a groove that mates with the outer cover ....and you do NOT want to pinch the wire from the points. You might as well check the on-line fiche and see what it is saying now, could be changed again! I find the K bike O-ring and a fast drying rubber cement to work well over the years.

BMW has a piece of rubber available to help block off the mechanical tachometer takeoff area. The worm, etc., at the engine case, can be left in place. The seal is 63-23-1-351-257. That part is used at various places on the motorcycle. Don't bother. Remove the original seal (save temporarily) and remove the tachometer drive gear. Use a sealant to seal a common dime (a USA ten-cent coin) in place in the hole. Use the original seal, or that number 63231351257, or, whatever you have, to hold the dime down.

61-12-2-302-574 Solid, better construction, flip-cap cover for the electrical accessory socket. This is a K bike part that fits.

Possibly no longer available?

46-31-1-244-384 Unconfirmed number for a blank plug to fill the RT/RS large round dash holes when no voltmeter or clock.

11-11-1-744-327 Black rubber timing hole plug.

61-21-1-230-392 Black rubber battery strap for /5 & later. The -392, brand-new, was measured & reported to me as being 26.41 cm (10.4") from center to center of the pins, which were 0.2" in diameter.

61-21-1-243-562 Black rubber battery strap for R65, R80G/S, R80ST, and some few others. Dimensions: ???

Dual stud mounts, black rubber, as used at battery bracket, fuel tank, diode board, etc. These are getting very pricey from BMW. Try this link, which has both American and metric threaded items, vastly cheaper ...and even has type with single studs, etc. http://www.mcmaster.com/#vibration-damping-sandwich-mounts/=11dac9v. I strongly recommend you do NOT replace rubber types if they came that way at the diode board, but, install solid metal aftermarket types.

46-51-1-234-785 black plastic cover for hex head of M8 bolts.

52-53-1-452-295 Metal seat post with notches. This is the notched locking post that screws into the seat pan. It is for some 1984, & many 1985 and later bikes. It may fit the earlier bikes, or can be made to fit. Because of the very high price, & that I am not sure that part will fit earlier bikes, I am recommending that you obtain the part from https://www.motobins.co.uk/. Search that website for part 91900S.

52-53-1-230-313 black rubber bumper used over the seat locking rod, that fits into the seat lock.

52-53-1-232-904 round bumper with attaching tit, used at the seats.

07-12-9-934-318 special type of C clip used to hold seat to right frame rail pegs. D6,0

61-31-8-050-134; 63-12-1-244-378 Chrome washer, side of /5 headlight shell.

61-31-8-050-136 rubber washer used with above Chrome washer.

61-13-8-050-138 rubber sleeve used with above two items.

46-51-1-231-233 Oversize peg that is to be pressed into the frame for the sidestand. The frame is to be reamed for an interference fit.

46-52-1-236-528 11 mm bushing used in /7 & later center-stands (to 9/80). Used with a flathead bolt 10 x 1.5.

46-52-2-301-704 Oversize bushing for center-stands, it is 13.5 mm and uses M12 x 30 bolt.

46-63-1-235-759 Closed end tube-grommet/rubber/plastic? ...to cover fairing screw sharp tips.

46-63-1-235-760 B 4.2-4BL MU BMW's version of Tinnerman nut for fairings. Number has been replaced by 07-12-9-904-144. This part can be listed in the catalogs in various ways, including BLMU and BL MU 4,2-4.

07-11-9-902-513 BL SHR BZ 4.2 x 19 the screw used with those Tinnerman's, above ....there is a short version 4.2 x 16 #07-11-9-902-514 which is replaced by -497.

46-63-1-235-510 cup washer for fairing taper head sheet metal screws.

46-63-1-235-512 screw used in joining sections of the fairing on RS and RT models.

07-11-9-907-944; -946 LIN BL SHR BZ 4.2 x 13 another of the screws used with the Tinnerman's.

07-11-9-902-467; -468 black phillips head sheet metal screw.

07-11-9-902-441 silver colored phillips head sheet metal screw 3.5 x 16.

07-12-9-948-739 3.2 rivet.

07-11-9-947-201 6 x 25 rivet.

46-63-1-233-909 expandable rivet used at windshield.

07-11-9-949-633 A 6 x 0.4 x 10 tubular rivet used at top of fairing area.

07-11-9-902-429 phillips screw 3.5 x 16 used at fairing rubber tunnel; replaced by -441.

21-21-1-231-463 ZYL SHR special bolt for clutch, up into 1980. Note that except for the R46 and R65 which use a smaller bolt, BMW changed from an early slot screw to Allen style. #'s for these bolts also have been 21-21-1-242-371 and 21-21-338-680 (for 1980+).

26-11-1-230-414 Special 12 point bolt, M8 x 1 x 14.5 for U-joint (early type used with split style lockwasher B-8 07-11-9-930-840). ANY Airhead found with the bolt and that split washer MUST have BOTH replaced with just a special bolt, without using a washer. The replacement bolt is 13 mm long, and is part 26-11-1-242-297. DO NOT FOLLOW ANY ADVICE, IN FICHE, OR OTHERWISE, THAT TELLS YOU TO USE THE ORIGINAL TYPE OF LONGER BOLT AND A LOCKWASHER. FOR AN EXPLANATION:

https://bmwmotorcycletech.info/tools.htm

scan down for Part II: and then scan further down to item 4.

33-53-3-054-174 27 mm thin nut used at the swing arm. Thread is 20 x 1.5.

33-17-1-230-301 One of the two basic pins (lengths have varied) used at that nut and swing arm. Thread is 20 x 1.5.

13-11-1-259-869 Screw for Bing vacuum takeoff tube; -870 is the washer. The screw is 3.5 mm x 0.6 pitch.

13-11-1-337-361 Screw for Bing CV carburetor tops. LIN SK SHR. Tapered head, M5 x 0.8 pitch, 12 mm long. Always use a faint amount of antiseize compound on the threads AND under the head.

13-11-1-254-761 Countersunk fillister head screw used at Bing carburetor enrichener cover, size M4 x 14 mm. It was replaced by 13-11-1-337-367.

13-11-1-254-738 Screw that holds the butterfly to the throttle shaft, two needed per carburetor.

13-11-1-336-900 METAL fuel T fitting.

11-12-1-337-818 Rubber pads used for quieting the cylinder head fins.

71-60-9-024-186 U shaped bolt used at cylinder crash bars, size 8 threads.

46-71-1-230-794; 46-71-1-237-759 U shaped flat clamp with one threaded end, used at cylinder crash bars, size 8 threads. The ABOVE THREE bolt/clamp units are used on the large SINGLE crash bar that covers both sides on the early airheads. There is a single type, one for left, one for right, and the clamp is 46-71-1-235-772 in chrome (now 46-71-1-230-794) and 46-71-1-237-759 in dull black.

OIL GALLERY METAL PLUGS:

The earliest plug had a single slot for a common screwdriver, 11-11-1-259-077, and is NLA, do not use them. The next type was an allen-recess plug, which is stronger, it is M12 x 1, 11-11-1-338-645, and used up to July of 1991. Then, BMW changed the machining at the area, and installed a 11-11-1-338-756, which looks like a small drain plug, & is quite strong. It is used with a solid gasket which is 12 x 15.5 x 15, 017-11-9-963-130. See the following article, item #4 in the article, for a further discussion:

https://bmwmotorcycletech.info/oilsketch.htm

Springs:

Springs are measured from hook end to hook end ...the length is the maximum over-all length, NOT stretched.

46-52-1-234-514 ? mm center-stand spring. No information length; wasn't

in fiche nor Snabb.

46-52-1-236-282 97 mm center-stand spring

46-52-2-331-805 111 mm center-stand spring

46-52-2-301-583 143 mm center-stand spring

Source for automatic advance springs: https://www.motobins.co.uk/

The headlight fork tube "ears", at the TOP, just under the top triple clamp, have a rubber bushing:

This is a sort of rubber O-ring. FOUR sizes were made ...you need to use the ones that fit properly on your bike:

31-42-1-232-527 is 3 mm thick.

31-42-1-230-696 is 4 mm thick.

31-42-1-230-697 is 5 mm thick.

31-42-1-230-698 is 6 mm thick.

There is also a rubber bushing or O-ring, located at the BOTTOM of the headlight ears; which is ONLY of one type and part number: 31-42-2-000-385.

Tapered Roller Bearings:

Steering head:

The steering head bearing is a common type 32028, 28 x 52 x 16 mm. BMW has used this number on all the Airheads, and even the Classic K-bikes. BMW dealerships have all sorts of prices for that bearing. There are variations on the 32028 part number, you may find 320/28X and others. The bearing may be listed as I.D. 1.102"; O.D. 2.047"; width as 16 mm. You can purchase this bearing almost anyplace, even a local autoparts store, which might list it as a A-32 bearing. Just ask for a tapered roller bearing, and provide these various numbers. Prices will be MUCH cheaper than many BMW dealerships ask. Do NOT ask for any special tolerance when you purchase the bearings. Do not use the 'sealed' variation. I purchase my bearings at a reputable bearing supply company.

Swing arm and wheel bearings:

Most swing arm bearings are 30203A, 17 x 40 x 12 mm; and are basically the same as MOST of the pre-1985 Airhead wheel bearings 30203 (some R45 and R65 are different). See the numbers etched into you bearings. The bearings are available both sealed and unsealed. I like them UNsealed, at both wheels and swing arm places. The swing arm bearings, if not of sealed type, perfectly fine on models with the cup-plate behind the bearing, should be greased from the hex hole in the swing arm pins. Do grease them now and then, particularly if you ride in wet weather or highly dusty areas a lot. Every few years I remove the entire rear end on my own Airheads, and do a more thorough job, that is, I hand clean those swing arm bearings. A good time to do this is when removing the transmission for a thorough transmission input spline cleaning and lubricating ...or other work, such as on the clutch, etc. If I am working on a bike and find sealed bearings at the swing arms, I puncture the seal, or remove the seal, so I can get proper greasing in the future into the 6 mm Allen adjuster hole. I leave the narrow area between swing arm and frame full of grease, which keeps water out. For the wheel bearings, they can be lubricated every tire change....but no later than every other tire. I do check preload then too. From 1985, the wheel bearings are a different type, not to be lubricated, just replaced as required.

My comments for the steering head bearings pricing and where to buy, above, also apply to the swing arm bearings & wheel bearings.

OTHER ITEMS:

Crankcase breather, disc style, as installed on the early Airheads (later was a reed valve, which can be installed if desired). See article 50B, which gets into some depth on the breathers, and shows a source for the old style too.

16-11-1-232-237 plastic washer that fits 4 mm screws.

16-12-1-240-513 16 x 2 rubber O-ring

Hearsay has it that a better O-ring for the VM clock is the Harley Davidson oil pump cover O-ring #26434-76.

Valve stems for tubeless tires/rims:

I use two types of valve stems on BMW bikes. The part numbers, details, are from MEMORY, so one should double check me here before ordering any. 36-32-1-452-748 is the kit consisting of the metal (steel) valve stem with O-ring and valve cap and nut. Nicely made product. These are used with Airhead tubeless rims as well as the cast K bike rims. For spoke wheels I use these with an 8 mm flat washer 07-11-9-931-697, which IS specified for their use. There is a 1-1/4" chrome valve stem, on a 45 degree angle, that I have used on the cast Snowflake rims. 0.435" holes, that I get from http://patchboy.com, part 17-561, has a special inner grommet.

Long lasting fuel hose:

http://www.mcmaster.com/#tygon-f-4040-a-tubing/=kh4623

BE SURE TO READ THE

FULL recommendations for fuel hose at item #11, here:

https://bmwmotorcycletech.info/fuelmiscl.htm

Rubber seal for the screw-in gas caps:

This is not the black trim ring, but the SEAL, originally RED (which broke after awhile); 51-25-1-453-148.

The black trim ring is 16-11-2-307-360. That is not a seal, but a trim piece; it also helps keep rain from getting into the 'shelf' of the tank under the cap (where a drain hole is).

23-13-1-241-484 Pin for use in the clutch arm (at rear of transmission). This pin has a flange, and won't fly out. This is used with a clip; 51-23-1-864-963. These two parts replace an earlier pin that uses a C clip. The early version sometimes lost the C-clip, especially when it was improperly assembled, and then a transmission ear got broken off. I highly recommend upgrading.

11-13-0-007-163; 11-13-1-744-329 magnetic drain plug used at transmission.

11-13-0-007-162 oversize magnetic drain plug used at transmission and rear drive; believe is used with oversize gasket-washer 07-11-9-963-259. Original size 14 x 18 mm; larger was 16 x 20 mm.

Explanation: Drain plugs and their crush washers are available in oversizes. Example: The standard rear drive plug is 11-13-0-007-163; oversize is 11-13-0-007-162; standard crush washer is 14 x 18 #07-11-9-963-213 and the oversize is 16 x 20 #07-11-9-963-259.

11-41-2-343-498 magnetic drain plug ....not from an Airhead. Used on some F650 models. M18 x 1.5. Used with washer 11-31-2-343-091.

23-11-1-230-599 hollow breather bolt used at transmission speedometer cable and battery.

07-11-9-905-660 special set screw, MAY have slot, M4 x 6 x 3, neutral switch on /5.

07-11-9-941-332 3 x 18 roll pin.

07-11-9-944-651 4 x 10 roll pin.

07-11-9-941-471 5 x 50 roll pin.

07-11-9-941-475; 07-11-9-941-470 5 x 60 roll pin.

07-11-9-941-485 6 x 16 roll pin.

11-42-1-335-394 Special 23 mm bolt used at the oil filter cover thermostat, to enable draining the oil cooler. Do NOT use if longer than 23 mm! Some wrong length ones were provided by BMW. Photo of correct one & a bad one, is below. If you were to measure these, they vary a bit from 23 & 30 mm ....but not much. Note that the threaded ends are slightly rounded to protect the thermostatic element, and the rounding does not show up well in these photos. Whether or not the bad one is rounded at the end does not matter, because you must NOT use a non-rounded bolt. Typically you will find the "23mm" bolt to measure about 0.918" from under the hex to the tip; and the "30mm" one might be 1.184". If you have the too-long bolt, you can install a nut on it, cut the bolt to length, clean-up the end, rounding it a bit more than shown here, and now you have the proper shorter bolt.

Neutral switch for 5 speed transmissions and its spacer:

The STOCK and ORIGINAL 1974-1975 5 speed transmissions used neutral switch 61-31-1-352-153. If you have the shift kit installed, or you have a 1976 & later transmission, the switch is 61-31-1-243-097. For the -097 switch you must use ONE special washer, which is 61-31-1-355-262, shown in the fiche as A12,2 x 20 AL. DO NOT use a common drain plug gasket washer! Reports of BMW shipping the wrong washer have been seen. Tom Cutter measured a new one & it was 19.8 mm x 12.35 mm x 1.89 mm. Original new ones, which might fit better (?) are probably 2.0 mm thick. It is best to use a new washer, but sometimes the old one will seal adequately. For a complete article covering the transmission (5 speed) mounted (bottom) neutral switch, for sealing it from oil leaks, removing/installing, ETC. see: https://bmwmotorcycletech.info/neutralswitch.htm

61-31-1-243-454 Rocker switch, with cable; switch snaps into the place in the dash meant for it.

07-11-9-987-611 Lock bow clip. This thin "question-mark-shaped" round steel WIRE is used to lock the balls at the shift linkage and also at the hydraulic damper balls.

61-13-8-080-160 Rubber boot for the speedometer cable where cable fits the right side rear of the transmission. This item has been the cause of many transmission failures. Be sure yours is in excellent condition and sealing well against water coming downwards into it.

Axles (Steckachse):

/5 front axle, 14 mm diameter, mm total length, .....used up through 9/1974: 36-31-2-060-336.

After 9/1974, front axle, 17 mm diameter, 253 mm total length: 34-11-1-233-490.

Rear axle, 17 mm diameter, 296 mm total length: 33-41-1-230-303.

BMW uses various spacers that I call "top hat spacers". BMW usually calls them Thrust Sleeves. These are tubular thin-walled spacers made of metal, with a brim on one end. In Airheads prior to 1985, on twin shock models, at the rear wheel, these are used to space the wheel the appropriate distance in the swing arm and to fit the wheel the proper distance onto the splined output of the rear drive. They are also used on front wheels. In general, for the wheels, the hat is located inside the seal, but not always, but in almost all instances, the hat may be inside the seal, pressing against the bearing inner portion. These spacers are also used at the swing arm to space it in the frame. These top hat spacers (thrust sleeves) are not the many-thicknesses-available thick small 'preload' spacer that do not have a hat/brim, and are often called Wedding Rings, that are used in pre-1985 wheel hubs to space the tapered roller bearings for their proper preload.

REAR WHEEL TOP HAT SPACERS:

36-31-4-038-142: This spacer is the stock one, it is typically 0.359" wide (height, usually with slight variances seen). I have seen them from 9.0 to 9.2 mm.

It is common to see the stock right side top hat spacer replaced by the wider-available one that is 10.7 mm, 36-31-2-301-737. BMW offers it for the purpose of moving the rear wheel slightly to the left (especially pre-1982), to allow installing a wider rear tire. Occasionally us tinkerers use an even wider spacer, 36-31-230-322, a top hat spacer that was made in two styles with the same part number! Both have a width (height) of 12.9 to 13 mm. An early version was extra wide on the brim portion; a diameter of 31.95 mm nominally. The "seal' surface of this spacer measures an O.D. of 21.95 mm.

Information on using top hat & other spacers for the wheels is found in articles on the wheels on this Snowbum site. Sometimes one must add flat spacers or move rear disc brake arm slightly, etc., when dealing with certain types of tires.

71-11-1-103-086 Screwdrivers. For Phillips, Pozi-driv, and Reed & Prince (Frearson) screws:

(see

https://bmwmotorcycletech.info/tools.htm article for lots more information)

A bit of School Time for you all in this section!

WHY information on screwdrivers? The proper tips and sizes make for reduced cam-out during installation or removal; and, less screw head rounding, easier screw removal ...and ...rounded screws are a sign of POOR workmanship!

The small BMW screwdriver with the red plastic handle that comes in the Airhead tool kit from BMW has a Phillips-looking tip, which removes/reverses (there is a flat single slot type tip on the other end). This is not a well-designed nor well-made tool. This screwdriver does NOT have a Pozi or Reed & Prince type of tip. The red handle will not take a lot of torque, and the tips don't fit ANY screw all that well. I never carry one of these, preferring a better screwdriver, such as a Snap-On brand, with the built-in chamber for the removable and hardened tips I want to take with me. The handle of an aftermarket screwdriver will be larger and much more comfortably usable, & will still fit the tool bag and tool tray. Just one reason for a PROPER fitting screwdriver tip is that Bing diaphragms fail rarely, but you really should have, and may well need, the proper screwdriver and tips with you. You want to at least have a #2 phillips tip and a medium sized single slot tip ....and any others that you need.

Bing carburetor top "Phillips" screws may not really be Phillips screws, they just look like one at a quick glance. They could be Phillips ...or ...could be 'Pozi' type, or a bastardized version of Phillips or Japanese types. Single slot screws are also seen on the tops. The ancient aircraft tip called Reed & Prince (also called the Frearson) works OK on the Pozi screws ...as, of course, does the real Pozi. The Pozi-tipped screwdriver is excellent for removing the "Phillips type", if the Phillips is quite tight.

Japanese JIS B 1012: These are different, look like Phillips screws, & CAN be used with a Phillips screwdriver. These screws are identified by a single dot or a tiny x, on the head.

For a much more complete treatment of these, AND various other screw heads:

http://en.wikipedia.org/wiki/List_of_screw_drives

Install carburetor top cover screws with a bit of anti-seize compound on the threads & on the taper. If the carburetor top screws are frozen, you can try a variety of things, see my carburetor articles. This includes valve grinding compound for a better grip by the screwdriver, but I prefer a substantial metal block underneath and an Impakt Driver.

Tips for interchangeable-tip type tools are available from a variety of sources, including Snap-On. YES, the Pozi IS available. The only critical 'Phillips' (appearing to be) type screw place on our Airheads is the screws used on the top of the Bing CV carburetors ....although some would argue additionally for the screw that holds the instrument pod umbilical cord to the pod, but the problem there is just over-tightening, not removal. Some have installed Allen head screws at the carb tops. That is OK, but don't over-tighten, as many of these have a very small allen size; can round-out more easily. I don't like Allen's there. Some early Bing carburetors came with common single slot screws. Bing has shipped BOTH Pozi & Phillips screws on later carburetors. Be sure that your screwdriver fits them properly, & do obtain a Pozi #2 or Reed & Prince screwdriver or tip. Remove the screws one at a time, coat the threads and taper with antiseize before replacing the screws ....you will appreciate this hint, later on.

Real Pozidriv screws have some radiating lines to indicate they are not Phillips type.

Little known facts: Phillips screws & screwdrivers were not originally designed to prevent over-torquing; that is, they were not originally designed so the screwdriver would slip (cam-out) after a certain amount of torque is applied. That came about as tooling got worn, and then became a 'feature'. Because of the specific design of the side tines of the Phillips, one needs different sizes of screwdrivers, as the wrong size will not fit correctly.

Here are photos of the Pozi-Driv screw, and the screwdriver tip. Note the differences from your Phillips! Note the radiating identification lines on the screw!

See https://bmwmotorcycletech.info/tools.htm for more on the Phillips/Pozi and the Reed and Prince (Frearson). For a much more complete treatment of these, AND various other screw heads:

http://en.wikipedia.org/wiki/List_of_screw_drives

Remember! .....rounded-out and otherwise messy screw heads are a sign of POOR WORKMANSHIP!

Discussion of 'locking' methods for screws, bolts, nuts, etc.:

It's more SCHOOL TIME!

The reason for having screw & bolt threads is to prevent something from loosening. One of several more reasons is to maintain a specific clamping force between parts. These parts could be brake caliper halves; a bolt holding a bracket to a casting; or any of many millions of clamping and other reasons. I am sure you learned nothing from this paragraph.

But, almost every person, including some with degrees in mechanical engineering, do NOT really know about how a simple screw or bolt or same with a nut, actually works. This can become a safety issue, if you substitute something where the factory had specific reasons for something ...or; many other things could be discussed here.

The actual holding forces in most fittings/fitments ...is NOT the force/pressure in or from the threads from their clamping torque! The actual holding force is the contact of whatever is against the underside of the head of the bolt. This is often very difficult for some to understand. The threads only enable the contacting pressures to occur ...and to help maintain the pressure. This is not some esoteric nonsense, as you will see.

A gross demonstrable example of this in your Airhead is the alternator rotor and crankshaft nose. Two tapers, a male & female, provide all the holding force, once brought together by the central allen bolt. It takes a considerable force to separate these pieces, once tightened, and then even with the original bolt removed. The reason is the full 'area' (let us say in square inches) of the tapers in contact with each other. This area is vastly larger than under a bolt head, if the rotor was held to the crankshaft by only a bolt contact method instead of tapers. There are other taper fitments in your Airhead, the most prominent is on the rear end of the output shaft of the transmission, with the mating female taper being in the flange that the U-joint bolts to. One could take this a bit further in description, and mention that the output flange flat area mates with the U-joint flat area, providing a very strong connection, and that the 4 special bolts at the U-joint flange provide the hold-together force, but the transmission of the force is primarily the flange flat surface. I am well aware that this concept is hard to believe for most of you.

Other examples might be where highly finished surfaces touch each other ...very little clamping is needed to allow large forces. I fully understand that this is a hard concept to get your brain around, particularly with common bolts holding flat surfaces together. One of the demonstrations in engineering classes consisted of two modest-sized flat plates with handles. The plates were very flat, highly polished, and a drop or three of water or oil was applied to the plates, they were then pushed-together. You could NOT pull them apart with your hands, only slide them apart.

For the example of the Airhead alternator rotor taper and its fit to the crankshaft taper, you can remove the existing single bolt, and you will be unable to remove the rotor, without the special hardened long bolt with special threads, etc., that is designed to force the rotor off the crankshaft. The forces, or call it pressure, that two tapers have with each other are very high. When the tapers disconnect, it is usually with a considerable BANG noise!

You do NOT want something to 'loosen' when you do not want it to; yet you want to be able to unfasten something when that is needed. Let's get back to discussing that output flange and U-joint:

You are probably aware of a mistake made by BMW, when the company specified a split type of lockwasher for the 4 bolts that hold the driveshaft universal joint to the transmission output flange. Split lockwashers are generally made of a hard spring material that has a quite modest amount of ability to distort (flatten), and the split area of such lockwashers have sharp surfaces, which can dig into and thus grab the surfaces they come in contact with, and it takes a bit of pressure to then flatten the washer. Some driveshaft U-joints became loose, disconnected/unfastened, and tore off the back of the transmission or caused other serious problems. The split lockwasher was NOT the proper bolt locking method. Think about what happens to that lockwasher as you tighten the bolt. The lockwasher is under a lot of stress, it is somewhat brittle, and rotating the bolt can tend to try to not only flatten the lockwasher (which is already 'twisted' slightly on purpose), but the bolt might actually try to expand the diameter of the lockwasher, and the brittle material could break. THINK ABOUT IT ...AND LOOK AT A LOCKWASHER, SLIP ONE OVER A BOLT, AND CONSIDER HOW IT REALLY WORKS as the bolt is tightened. The turn the lockwasher over, put it back on the bolt, and look again. Think about making the lockwasher split in the opposite direction, and the effect by the bolt in tightening and loosening! Getting any ideas? Yes, something as simple as a cheap lockwasher, caused $$$ damage.

In fact, use of NO locking washer at all would have been FAR better! THAT is what BMW recommended later, & furnished a shorter bolt, so the original bolt would not damage the forward-located seal after passing through the flange, without the thickness of the lockwasher. I like clean/dry threads here and adding a drop of medium Loctite, for extra insurance; and, I prefer to measure the torque when installing.

Repetitive stresses & forces, particularly sudden sharp shock forces, all tend to loosen things. It is common in high forces areas that if something is even a teeny bit loose, intense LOOSENING AND BREAKING forces arise. Very critical items can be such as wheel bolts/nuts; brake caliper mounting bolt & nut; or something very simple like a single small screw holding an electrical connection.

In some situations, tightening & clamping forces are EXTRA CRITICAL. One such on the Monolever and Paralever Airheads is the REAR WHEEL BOLTS. NEVER lubricate these items! NEVER use antiseize compound on them! The wheel is aluminum alloy and expands and contracts much faster than the steel bolts, so proper tightness is a must. BMW has a design method for using those bolts, which are of a certain size, length and shape ...and must be tightened to specifications, under which the proper tension is applied. Failure to properly install the bolts can result in an 'exciting' and very dangerous departure of the rear wheel from the motorcycle!

What should you know about methods of fastening things where mechanical stresses can occur (they CAN occur just from normal day to day temperature changes, not just mechanically induced stresses from riding or even with the engine on or off)? Obviously, the more stress cycling there is, the more likely for a threaded fastener to loosen. Using numbers of stress cyclings (official terminology is number of load cycles), versus actual clamping load, the following is information I believe you can trust:

1. An UNsecured (no locking method) bolt & nut is generally the worst case ...somewhat depending on materials, steel-into-aluminum?, steel-into-steel? Strength drops quickly & constantly. Similar, only a bit better, is a bolt with a split ring lock washer & a nut; & only a bit better than that is a bolt with a toothed type lock washer & a nut. In general, split and sometimes other types of lock-washers, are NOT appropriate where forces applied are irregular, or recurring.

2. Next is an elastic stop nut. The strength drops somewhat quickly with load cycles ...but then deteriorates only very slowly with additional cycles. This is why this type of nut is used in some critical applications.

3. Next is a bolt with the underside of its head being a saw-toothed flange.

4. The best is usually a bolt that has the correct type of Loctite (or similar) product applied and the threads were clean and dry before the application of the Loctite.

The difference between #3 and #4 can be small. The difference between #1 and #2 and #3 or #4 is HUGE.

Revisions:

Initial upload: 02/25/2003

Specific updates/changes MAY not be identified here.

07/12/2016: Major update. Clarity, layout, scripts, H.L., metacodes. Quite a few changes to part numbers and descriptions.

08/11/2017: Update banjo bolt washer-gaskets. minor, again, 09/29/2017.

10/02/2017: Clarify flywheel bolts details.

10/22/2017: Clarify engine studs for p/n and lengths. Begin some minor html changes.

01/11/2018: Rework entire article. Clean-up. Clarifications. Corrections. Reduce excessive html and colors and fonts. Add 10pxl margins.

12/20/2018: Re-do the section on the rear drive stud, and add photo.

04/02/2019: Go through entire article. Clean up, and check on some possibly out of date or confusing part numbers and specs.

07/22/2020: Add axles.

08/29/2021: Update info on breather discs, providing a link.

© Copyright 2021, R. Fleischer

Return to Technical Articles LIST Page

Last check/edit: Wednesday, February 23, 2022