Noisy valves; leaded fuels;

valve seats; sick valves;

valve guides; valve springs;

valve seals; aftermarket valves;

bead-blasting. Upgrades. ETC.

© Copyright 2024, R. Fleischer

https://bmwmotorcycletech.info/valves.htm

Article 60, sub-section 5

MUCH of this entire article is my personal opinion.

I DO have some other folks opinions here, and so identified.

NOTE: Oak wrote a lot about the valve and valve seat problems over the years. After his death in 2017, a combined article by Oak was printed in the Airheads Beemer Club monthly publication, AIRMAIL. That in-depth article is in the September 2022 edition. If, after reading my article, you are interested in a somewhat different presentation (with more detailed information on the metallurgy for instance, etc), then I HIGHLY recommend you obtain a copy of Oak's material and read it.

NOISY VALVES and PRELIMINARY INFORMATION:

Contrary to popular belief that the Airhead valves are noisy due to excessive valve tip-to-rocker clearance, noisy valves are quite often really the result of excessive rocker arm end-play due to improper end play adjustment. In some instances, valve seat wear or too wide a valve seat will cause extra noise. As the valve seating area gets wider from higher mileage (let alone someone grinding the seats & valves with too wide a contact area) the wider seat contact area causes an increase in noise. Worn valve guides can also lead to increased noise.

The RS and RT fairings will make the valve structures seem noisier than the naked models. Early valve gear, the /5 in particular, are vastly more adjustable, & they are more tricky to set up as they can be moved all-about & need some extra care with alignment before tightening the head nuts, particularly when tightened beyond barely snug. The /5 has bushings in the rocker arms; they wear in an oval pattern, that wear can create noise. Extra life on them is available by moving them to specific places. This website has information on how to move the /5 bushed rockers to other positions, to gain more life before the need to re-bush. see: https://bmwmotorcycletech.info/headassy.htm which has a lot of information on the heads.

Models after the /5 up to 1984 were less and less adjustable for end play, and not very much assembly movement besides the small end play was available. 1985 and up are shim-adjusted for end play.

Wear on the needle bearings equipped rocker arms is usually very low. Sometimes a needle bearing will fail. Some were poorly made and will spit needles out the end that had a needle bearing assembly that was improperly crimped by BMW. Oak did an article on that in AIRMAIL, September 2004, but the information you need, expanded a bit, is here: https://bmwmotorcycletech.info/headassy.htm

It is NOT unusual to hear one cylinder louder than the other, & NOT unusual for them to get louder as the engine heats up; occasionally the reverse is true. Increasing loudness after warm-up is particularly so with the earliest pushrods, although that is a small part of the noise increase. There are rubber pads available to insert into the fins which do help some in reducing the fin-ringing. See the article: https://bmwmotorcycletech.info/quietingpads.htm

The proper amount of rocker end play is for OIL FILM movement when a rocker is moved up & down (rocker not under pressure from the pushrod); although there is an end-play specification for the 1985 & later models with the narrower rockers & plastic insert & end play set by SHIMS. Rocker end play must not be too tight. With the adjustment for valve clearance backed WAY off, the rocker must rotate smoothly through the entire rotary motion with no binding. Do not mix up end play which is an up and down movement ....and ....smooth rotation.

Proper torque on the 6 nuts is important. They must be tightened evenly, in a cross-pattern, ending up at 25 foot-pounds on an ACCURATE torque wrench. The FOUR rocker nuts & their stud threads are OILED before assembly. DO NOT use values of 29-31 footpounds as published for some early models. 25 foot-pounds is good and safe for ALL models of Airheads.

If you are interested in the various types of valve rocker parts, and information on rocker arm upgrades, refer to this article: http://www.largiader.com/tech/rockers/

Do not fail to read this:

https://bmwmotorcycletech.info/setvalves.htm

Leaded fuel, use, implications, etc:

Leaded gasoline has not been available for road vehicles for many years now in the USA. Leaded fuels are still available for piston engine aircraft. Use of leaded aviation fuels in the U.S for on-road use is illegal. Many years ago, when it was totally normal for tetraethyl lead (TEL) to be in automotive fuels, some gasoline's contained ethylene dibromide (& some other additives), which helped flush the lead from the combustion chamber, & reduced any deposits under the exhaust valve tulip head. Still, a considerable amount of lead & other deposits occurred at idle & very light throttle situations & also where the heat in the combustion chamber was not high enough to burn off & flush the deposits. It is my belief that Chevron's Techron secret ingredient, then, was ethylene dibromide, or something similar to it. Techron has been reformulated more than once, & I do not know if lead scavenging substances are now in Techron ...or in ANY road gasoline's. There are two types of Techron sold now (only one type, I think, is available from gas station pumps), one for fuel injection cars & one for carbureted cars. I do NOT know of the differences, if there really are any. I do know that Techron DOES work for any engine, to help keep deposits down.Adding leaded aviation fuel to road gasoline in the very small amounts (noted later in this article for valve & valve seat protection) will NOT result in excessive deposits in cylinders or damage to spark plugs. The amount of lead in leaded car gas all those many years ago was quite high when used to increase octane; vastly LESS was actually needed for PROTECTING the pre-1981 BMW valves & valve seats. SMALL amounts of TEL, from using a SMALL amount of leaded aviation fuel, is helpful for early Airheads & many garden equipment engines, etc.....in general, good for any engine that was designed for leaded fuels, & not designed for UNleaded fuels. The amount needed for valve and valve seat protection is quite small, as you will see later, in this article.

Tetraethyl lead, also called TEL, (or, just "LEAD", if used for gasoline) is VERY dangerous if absorbed through your skin when in pure form. You are unlikely to be exposed to concentrated TEL. TEL compound has TWO major engine effects. First, in sufficient strength it raises the octane value of gasoline, especially important in WWII aircraft engines with very high output per cubic inch (back then) & flown at high altitudes. Especially high octane values were needed for supercharged or turbocharged (or both) engines in WWII. The original purpose for using tetraethyl lead was specifically for raising octane. While that is commonly known, what is not, is that using TEL allows better volatility of the gasoline, with some side notes I will keep out of this discussion, about Reed Vapor Pressure. Some of those aircraft engines required 145 octane gasoline. Use of TEL in gasoline's was incorporated in car gasoline's for decades because it was cheaper than more costly & sophisticated refining methods. This was so even when the lead (TEL) was sold expensively by the then monopolistic Ethyl Corporation, as the price was kept such that refineries still found it cost effective to use it. Many decades ago, premium higher octane gasoline's for road vehicles were simply called "Ethyl". There is a lot more to that story, this is a very simplified version.

Lead is not good for human beings nor animals nor birds, whether breathed in from the air, or by skin or other contact. It is particularly bad for young folks, as it has many bad effects, especially on the brain. Octane-raising strengths of lead additives are responsible for short spark plug life. Lead conducts electricity, & is slowly, sometimes not so slowly, deposited in some sort of conductive metallic form on the center ceramic insulator of spark plugs. When enough is deposited, it will electrically short out the spark plug; usually this begins as irregular & annoying misfires & wasting of fuel, not to mention accelerating all sorts of combustion chamber deposits, which raise compression ratio and cause other ills, such as pre-ignition. Deposits of lead compounds & other substances found in leaded gasoline are left on valves (even under the valve heads where the deposits porosity absorbs fuel & causes problems), in the combustion chamber, & on pistons. The problem is especially bad on valve guides, promoting wear. Combustion chamber deposits raise compression ratio, cause some types of wear, worsen 'hot carbon spots' causing pinging (pinking) and/or pre-ignition, and sometimes even high power detonation. Lead manages to get into the lubricating oil, mostly via piston ring blowby .....and some from valve guide clearances, .....& tends to collect & stay in the oil. That is one of the reasons, back in leaded fuels days, that one should never get used engine oil all over your hands, besides the fact that the oil got contaminated by other things. Back then 3,000 mile oil change intervals were the norm. This is often still promoted today ...but NOT by car companies ...who know better! Imprecision of machining greatly contributed to the contamination of crankcase oil, because cylinders were either cast iron or iron or steel sleeves, and roundness (and roundness stability over a temperature range) was not easily capable of being anywhere's near the precision of today's vehicle cylinders, hence there was considerably more blowby.

Today, used oil is not nearly as dangerous, but there are still unpleasant things in used motor oil from combustion by-products & it is best not to have skin contact with used motor oil.

TEL, or similar lead compounds, were actually used long before WWII for octane-raising. Before mid-1975, catalytic converters were not used on cars hardly at all to reduce some types of engine smog emissions; but were made mandatory for the 1975-1976 model year and beyond, by the USA EPA. Catalytic converters are POISONED by lead, so there was a strong reason to eliminate TEL from road vehicle fuels in the mid-seventies ....but total elimination took many years, partly from the accumulated lead in storage tanks, tanker trucks, etc.

I think that the 'seat' & 'valve' protection effects of TEL were something noticed later on, after WWII.

Tetraethyl lead in vaporized form leaves a microscopic layer of lead on the valve & valve seat; some folks call this 'cushioning'. It was originally nearly universally accepted that without the lead little bits of carbon might promote microscopic welding of valve & seat. The valve lifts again & some more microscopic metal is removed, leading to pits & valleys. That this really happens is debatable, and the true story is a bit different, and has to do with cast iron valve seats, and Oak covers this in the article of 2022, listed at the top of this article.

Lead is, at very high temperatures, A LUBRICANT & TERRIFIC CONDUCTOR OF HEAT. While the belief by many was that a bit of lead makes the seat & valve much less likely to weld at scattered microscopic places AND the valve head heat is more readily transferred to the seat, newer theory ...such as for our pre-1980 Airheads ....is that it is the normal rotation of the valves (you DO know that the offset rocker arms cause the valve to rotate & also cause egg shaped wear on the valve guide?) that is causing the wear. In MY OPINION, this is actually an additional factor & does not necessarily negate the original beliefs. There is more about TEL, below.

Airhead valves and valve seats problems:

BMW Airheads had TWO problems, and MANY people mix up these two. The FIRST problems began showing up on the 1980 & later models. This problem did NOT show up right away, with the phase-out of leaded fuels, as many thought it would, on the 1979 & earlier models with cast iron seats. BMW had changed the 1980 (& later seats through 1984) IN ADVANCE PREPARATION for the soon-to-be-ONLY-type-of-car-gas; UNleaded gasoline.

The history of the phase-out of TEL as an additive to gasoline is very complicated; I am NOT going to get deeply into this, suffice to say that it came about in stages, and a limited phase-out of leaded fuel began in the USA in 1973, in a very slow & very limited way. In 1992 California banned TEL. Effective Jan 1, 1996, the Federal Clean Air Act did the same for the entire USA. In both California & later the entire USA, the ban was for ROAD-GOING vehicles.

For the nerdy: the 1996 law (and to some extent the earlier laws in the seventies) BANNING TEL had a limiting specification for testing of gasoline's; that amount was extremely low but set an OK level for various reasons, one of which was due to residual lead in major and minor storage tanks & fuel distribution lines, etc. For Europe, the phase-out schedule was somewhat different.

There are still some few places in the world where TEL is still used for road vehicles. The usage in piston-engine aircraft continues (at a lower concentration of TEL), while research, etc., is ongoing in trying to find an acceptable substitute for all common piston-engine'd aircraft, some of whom have high compression ratios and need higher octane fuel. Only one OFFICIAL RECOGNIZED LEGAL SOURCE for TEL exists. There are likely a few other sources, perhaps in China.

The new valve seat material introduced in 1980 (not fully until 1981) by BMW was a SS, high nickel-chrome alloy. NOTE that this seat material can be identified by a SINGLE scribed line on the inside. The later (1985+) PROPER material valve seats have TWO scribed lines. Problems with 1980 to 1984 models became more & more evident & BMW dealerships & BMW blamed problems on poor maintenance & rider abuse ....for the problems showing up on U.S. motorcycles. Many of these engines developed deformed & overheated exhaust valves ...some were swallowed up in the seat bore. The R100 models were the worst. They develop more heat than the smaller engines. There were other contributing factors, including lean running engines, the pulse-air injection system, higher power output on some R100 models, etc.

The 1980-1984 valve SEATS were not damaged but somewhat at their edges, certainly not like the pre-1980 models (which became problems only later). Some 1980-1984 Airheads got valve jobs, and the same bad situation started-up again. It seems that BMW made an 'improvement' for the 1980 to 1984 models that made things MUCH worse. There is a German word for that sort of thing: Schlimmerverbesserung. Sometimes, particularly on the smaller Airhead engines of 1980-1984, problems with the valves/seats did NOT show up for quite some miles ...and ...often either never showed-up, or only at exceptionally high mileage.

The first indication of a problem is almost always rapidly closing-up of valve clearances, ESPECIALLY & PRIMARILY the exhaust valve. This is true for both pre & post 1980 models, which differ in the cause.

Note that a BMW airhead with mechanically sound valve gear: good seats, valves, guides, of the later (1985+) proper materials (or, pre-1980 parts with leaded gasoline's) will normally not have valves closing up more than about .001" to .002" per 5000 mile adjustment interval. Those riders that like to use the area near or at red-line rpm, may find the valves closing up faster. With a good top end condition, closing up of as little as .0005" per 5000 miles is NOT unusual.

Meanwhile, as the R100 engine'd 1980-1984 bikes were having the most problems, the 1979 & earlier bikes, were still mostly OK. Everyone 'KNOWS' that the earlier cast iron seats won't hold up to unleaded gasoline! What was going on? Well, there was plenty of lead still around, in the distribution system, inside tanks, etc. It takes only a minuscule amount of lead to protect CAST IRON valve seats. I also believe that some seats were heat treated better than others, & since the unleaded problem was not known, there was no reason to tighten heat treatment specifications (I am NOT sure this last sentence is correct, it COULD have just been poor quality control).

About 3 or 4 ounces of aviation leaded gasoline, in the commonly available grade called 100LL (100 octane Low Lead) is needed per gallon of UNleaded car gas, for good protection on the early 1980 and all 1979 & earlier Airheads. On a practical basis, less than this amount seems OK, & many have had good results by simply adding a cupful (a cup is 8 ounces officially, but in practice is 5-8 ounces) every few tank fill-ups. NOTE that this usage for road vehicles is illegal in the U.S. Still, many who have lawnmowers, etc., with old type seats (many with NO inserted seats) use a small amount of aviation fuel in their tanks. I add a small amount of aviation fuel to the tank of my 1969 snowblower, which has the original unopened engine, and it works hard every Winter. Some owners of 1980 Airheads with the original type of valve seats do this too as 1980 was a crossover year, so some 1980 models are helped. The exact crossover may or may not be September 1980.

130 and 145 octane high lead aviation fuel was only for racers and old military aircraft, and is available, but difficult to find....and I will not discuss these any further than this mention.

Leaded and unleaded 87 octane fuel and low and high leaded 100 octane fuel has been available, depending on the airport, and this is from quite some time ago. Today, the only leaded gasoline found at nearly all airports is 100LL. Originally, low lead was 4 grams of TEL per gallon, and high lead was twice that amount. So, 100LL, everyplace, until recently, contained 4 grams of TEL per gallon. It is commonly accepted that approximately 0.1 gram (some say up to 0.3 for high protection) of tetraethyl lead per gallon provides reasonable valve seat protection. This is FAR LESS than the amount required to boost octane any appreciable amount. Using the 4 gm/gal specification type of 100LL aviation gas, and commonly accepted TEL protection levels, only .025 gallon of aviation gas is needed per gallon of unleaded car gas. A gallon is 128 ounces (U.S. measure). Thus, only 3-1/4th ounces of aviation gas per gallon of unleaded car gas was required for acceptable protection. Less is usually needed, as aviation piston engines normally work very much harder than our Airheads. Today, the amount of TEL in aviation 100LL fuel is 2.12 gm/gal, & the amount of aviation fuel needed per gallon of unleaded car gas needs to be doubled for protection of your pre-1980 (and some in 1980) engine. Still, a cup of 100LL per 5 or 6 gallon tank in the Airheads, is enough for pretty good protection.

Note, again, that the reduction in TEL for aviation fuel from 4 gm/gal to 2.12 gm/gal still leaves more than needed to protect your valves and valve seats. That is why a quite small amount of aviation gasoline can put into a tank of road-type gasoline in your motorcycle (or, other vehicle, or whatever), and be enough for reasonable protection.

Some people do use aircraft gasoline as an additive. As noted, it only takes a SMALL amount TEL to protect valves & seats (SOME 1980 and later through 1984, but all PRE-1980). It need not be in every tank (although that is best). It was residual amounts in tanks & delivery systems that kept some 1980, but all 1979 & earlier bikes in good condition for YEARS after the lead phase-out (in many instances). 'Race' additive WITH REAL TEL MAY still be available, expensively. However, you need so little lead, that aviation fuel costs as an additive is very small in actual usage. Aircraft gas, typically costing about 50% to double more than car gas, can be stored in a metal can for many years. Aviation fuel does NOT gum up or otherwise deteriorate like car fuel does .....& a cup or two cups per 6 gallon filled motorcycle tank, works well to protect the valves and seats. If you have a 1979 or earlier (1980 in some instances), & are seeing fast exhaust valve closure, you might, illegally of course, add 8 to 20 fluid ounces of aircraft 100LL gas to your airhead's tank when filling-up (assuming empty tank and 5 or 6 gallon tank).

If you have a late 1980 & later, this addition of lead will NOT stop valve recession as far as I know, & it is not clear to me if it will help in the slightest; although it MIGHT due to lead being a better heat conductor. For that purpose, you would need at least 3 cupfuls of aviation gasoline per 6 gallon Airhead fuel tank fill-up. I've never run tests on 1980-1985 engines for testing this theory. IF YOU DO, PLEASE LET ME KNOW!

The best fix is a top end job with new BMW-sold or equivalent valve seats. It is tricky to properly install the seats, you need about .005" to .006" of interference fit, & you need to heat the head to about 500°F ...& KNOW what you are doing. Auto machine shops are totally INadequate to do Airheads ....you need someone like Ted Porter, the late great Oak Okleshen, Randy Long via Tom Cutter ....etc.

Why did not BMW do something sooner? My belief is that BMW did NOT BELIEVE the problem REALLY existed ....with no reported problems in Germany and Europe (different phase-in schedule for Unleaded gasoline in many areas helped this idea along). The truth may be mixed, and I think BMW did not tear down engines with valve problems to inspect carefully and thoroughly, at least not early-on.

There are "lead additives" available, but, to my knowledge, none of them now really contain TEL, at least in the USA. Unless an additive container states specifically that it contains lead, or TEL, it is unlikely to do much to help the 1979 (and some 1980) & earlier models; and probably not the 1981-1984. There are some possible exceptions, and links later in this article may give you some ideas for products that might help.

Some have been confused by their failure to read carefully. Please note that the closing up of the valve clearances tends to happen more rapidly with the early models (1979 and earlier), from the lack of TEL in the gasoline. The damage is to the valve SEAT, not generally to the VALVE. After 1980, the closing up of valve clearances is usually slower, but the problem is caused by the wrong valve seat material (fixed by BMW in 1985), but the damage is generally to the VALVE, not to the SEAT. Many times the 1979 and earlier models are kept running fine by adding some TEL (aviation fuel). If the 1979 and earlier get new 1985+ type valve seat, all the problems goes away; and, often the exhaust valve is re-usable. For the 1980 and later, installation of the 1985+ seat is needed, and the valve is usually not re-usable. Note also that bad things USUALLY happen quicker with the R100 engines, and much much slower with the smaller engines, such as the R65.

A slightly different way of explaining things:

In early 1989, most major gasoline producers suddenly eliminated leaded fuel entirely. This was done in anticipation of the 1992 California law, and the coming Federal law. With underground tanks being flushed by being used with new type unleaded fuels, it was not long until some 1980, & MANY 1979 & earlier bikes were having problems. Major wear patterns, sharp & well defined steps in the valve SEAT. The exhaust VALVES in the 1979 & earlier models were generally OK. MANY 1980 & later models began, as lead in the fuel distribution system was eliminated, to show damage, mostly to the VALVE, as the valve was unable to cool enough, as the seat did not absorb & transfer heat well enough. ALSO, IMO, BMW had more than its share of problems in heat treating the original cast iron valve seats ....as previously GUESSED by me. The problems were hardly seen on the cooler-running smaller bore models. Keep in mind these two very distinctly different causes for problems with 1979 & prior; &, 1980 through 1984. BOTH end up causing closing of exhaust valve clearances. Keep in mind, also, that the smaller bore Airhead engines have fewer problems, with less over-all heat developed. SO: TWO distinctly different causes, depending on whether the engine was a 1979 & earlier, or a 1980 & later ....AND, sub-problems, in that SOME 1979 & earlier cast iron seats were 'harder' (resisted heat problems) than others, & that some engines ran hotter. SOME smaller bore engines of 1980 & later did not have problems, or not soon.

Fresh valve jobs were not a lasting repair, problems often returned shortly thereafter.

The BMW 'production fix' SUPPOSEDLY occurred in 1985. NOTE that SOME 1985 and 1986 models did NOT have the full fixes.

The fix for BOTH problems is to install the latest (1985+) VALVE SEATS that BMW sells. This material has a vastly improved thermal conductivity & is immune to not having lead in the fuel. These valve seats are very good, & have TWO scribed lines inside. The 1980-1984 'bad' seat material can be identified by a SINGLE scribed line on the inside. RE-SAID: The FIX for ALL the prior-to 1985 Airheads with valves &/or seat problems... is new valve seats of the 2 scribed lines type. You may need exhaust valves. Aftermarket seats may be OK.

It is possible that using a small amount of tetraethyl lead MIGHT make our old 1980-1984 OR even the 1985 type of updated valve jobs last longer, due to the better heat transfer of the lead ....but I have no specific information; this is pure off-the-wall-speculation, without a shred of proof on my part. That lead does help the pre-1980 original valves & seats is unquestionable.

The new seat material is not what folks generally think of as SS, rather, it is a 'tool steel'. Sometimes the early valves, if in good condition, are reused during the seat installation and 'valve job'.

References...

1. Link bad, removed.

2. https://en.wikipedia.org/wiki/Tetraethyllead

3. https://en.wikipedia.org/wiki/Antiknock_agent

4. http://www.shell.com/business-customers/aviation/aeroshell/knowledge-centre/technical-talk/techart12-30071515.html

There are dozens of applicable other references, easily found.

WHEN should you consider a proper valve & seats job?

I WISH there was some absolute information, but there is NOT. As a general rule, you are fairly safe in riding at reasonable rpm (keep away from redline!) on reasonable rides, even some longer ones, so long as most of the valve adjustment amount available is not near being used-up; and, that the valve clearance does NOT get close to zero. As the valve clearances decrease, the cooling time (valve on seat) is DEcreased. When clearance is ~~zero (actually, the exhaust valve starts getting too hot if the clearance goes below a few thousandths of an inch) the valve does not seal, & very hot gases are going by the exhaust valve-to-seat, causing red-hot burning metal. If you have the Pulse-Air system plugged or removed, especially on a R100 engine, you have a bit of additional safety factor.

The larger Airhead engines develop more heat & tend to decrease valve adjustment clearances faster. A problem can especially occur if you have been taking mostly or all short jaunts, & suddenly you take off on a hot heavy fast cross-country trip. An extended trip like that will use more horsepower more constantly, & the exhaust valve will heat up more. It is possible that you will find the valves closing up relatively fast. If you find the valves closing up several thousandths of an inch every 1000 miles or so, you are in a trouble area ....the BIG DANGER IS TWO-fold:

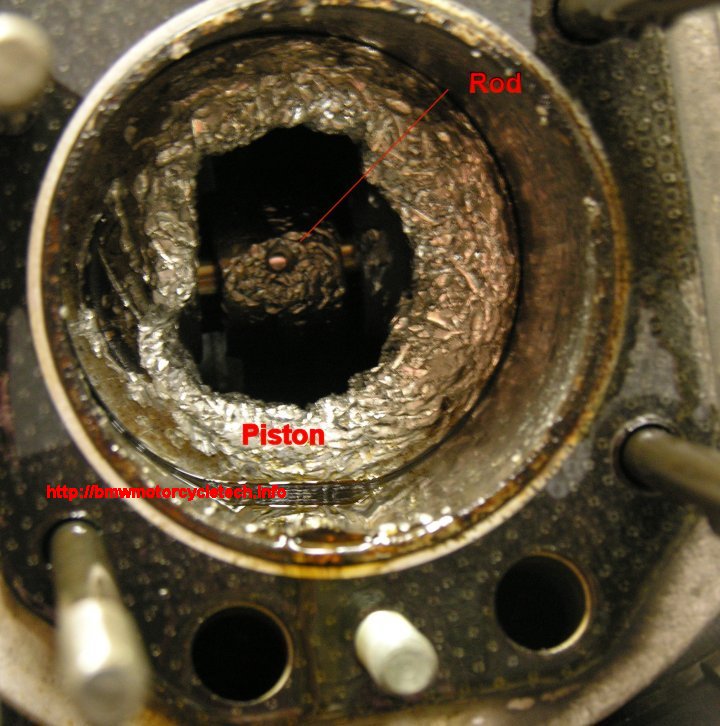

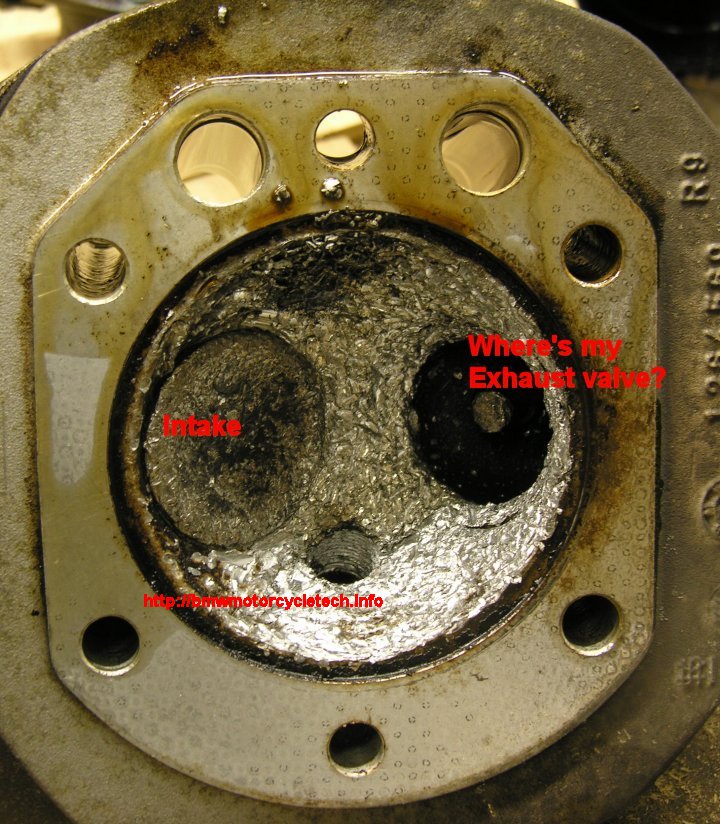

(1) You adjust the valves & continue adjusting them, & at some point the adjustment amount left is fairly-well-used-up, & a BMW valve tulip lets go, & makes a MESS of the inside of your engine. If the exhaust valve is a single piece aftermarket type, ...that type seems to have even more problems with handling heat, and can distort.

(2) You let the valves go too far with closing up & clearances start approaching or reach zero. This can lead to the same damage as in (1), or severe valve and seat burning problems, and parts of the valve tulip may disappear, doing plenty of damage, before the final act (loud, noisy, destructive, costly).

Here are two photos of what happens when a valve comes apart, or otherwise fails:

Some technical information ...covering a lot of questions often asked:

1. The old Luftmeister, CC products, & some other valves, are a ONE PIECE stainless steel valve. If you use such valves, they are usable (that 'usable' does NOT mean I recommend them!) with Martin & Wells Martite or Welltite seats. They have a chromed stem that wears OK in the guide, & a Stellite tip.

They are NOT hardened in the keeper slot area; the keeper slots wear, moderately quickly. The slots open up such that the valve cannot be removed from the guide without laboriously filing the end of the valve. The manufacturer, or others, may suggest grinding the keepers during original installation until the valve no longer rotates ...I SAY DO NOT! Guide clearance is critical for these valves. I highly recommend never using these valves & seats, etc., in combination ....or, frankly, never using these valves at all.Genuine BMW two-piece welded exhaust valves have better tip & keeper slot hardness & wear better than many other valves.

2. Kibblewhite's Black Diamond products are supposedly "OK". These are a one-piece SS valve, that are NOW supposedly hardened at those keeper slots. I am not a 100% believer. I think the slots wear excessively. There are some things nicely done on the valves, such as a machined tulip & a polished swirl finish. The tip is Stellite, & works well with the Martin & Wells seats ...although Kibblewhite also has matching seats of their own. Due to the hardening process, the valves are black, & do not have a chromed stem. The guide wear will be a bit faster due to that, & might even gall in the guides. Do NOT grind the keepers to keep the valve from rotating.

Others say that Black Diamond valves are not recommended. Generally, their reasons are that there is a thin coating on the stems that wears off, & the stems are soft. The reports to me that this problem occurred ...were with AMPCO guides. The type of guide might well be SOME of the problem.

There are problems with installing some valves. Minimally knowledgeable shops may grind the keepers so the valve does not rotate. IMO, this is a BAD thing to do.

I think genuine BMW valves are MUCH BETTER & WORTH the extra money ....because there HAVE been catastrophic failures of the Black Diamond valves. There have also been a few RARE failures of BMW valves, typically they were in the early eighties, with the bad valve seats, so the valves had been overheating & deforming for a long time. See the next paragraph. This is a situation where the BMW exhaust valve costs more money but I think it is wise to spend the money.

BMW exhaust valves HAVE come apart, but rarely, & ...IN MY OPINION ...when the valves have distorted excessively from the reasons explained in the article you are reading. Typically the clearance adjustment is considerably used-up, which informed you that you have a problem, because the valves had been closing up & you have had to set them wider, more often, for some time. Note that LUGGING the engines with LARGE amounts of throttle is hard on the exhaust valves, tending to overheat them. It is my belief that excessive lugging of even the usually unaffected by the early valve seats models, like the R65, is responsible for some catastrophic failures. BTW, the R65 uses a smaller stem on the valve, reducing its heat transferring capacity. I suggest being especially careful not to lug any Airhead engine, particularly for longish stretches of highway, like minutes at a time.

3. The BMW exhaust valve is TWO-piece, inertia welded, & pricey, but VERY good quality & performance. It is VERY rare for a BMW two-piece exhaust valve to come apart in service (keep in mind what I said above) ...contrary to rumors pushed by other makers of valves. The BMW chromed valve wears well in the guide, & the SS head works well with the later (1985+) BMW or Martin & Wells seats. The tip & keeper slot hardness seems GOOD, or even superior.

4. The BMW intake valve is a one-piece type of SS; a good valve. Others can be substituted. Be sure the guide material is compatible with the valve.

5. GUIDES: Here is where I don't like the BMW parts. BMW valve guides come already sized for stem clearance. This makes it convenient & fast for shops without proper guide honing & measuring equipment, but makes for a so-so valve job. After the BMW valve guide is installed, the inner diameter of the guide is larger where it sticks out of the head, & smaller inside the head metal area. If you hone a BMW guide until round, you probably will end up with excessively wide clearances. Thus, it is better to use AFTERMARKET guides with smaller I.D., so that after installation, they can be honed round, & will have correct clearance, & last a long time with no oil burning. BMW does NOT make such a guide. Thus, I recommend genuine BMW valves BUT USED WITH PROPER AFTERMARKET GUIDES, properly installed. BMW offered OVERSIZE STEM valves (both intake & exhaust) to be fitted where guides were worn. The information is available in SI 11 048 91 (2463). I have never used them & suggest they NOT be used. The proper fix for worn guides is new fitted guides, & NOT BMW guides. I do not use BMW guides.

The cylinder heads can get quite hot, particularly at the exhaust valve seats, exhaust valves, & exhaust valve guides. The guides are removed & installed with the cylinder head QUITE HOT, nearly 500°F (~ 250°C), same as the valve seats RR.

6. SEATS: BMW valve seats are PRICEY. Seats made in the U.S. are fine, & you can have them made to order. Installing seats requires a real professional who is very experienced & NOT just any automotive or motorcycle machine shop, etc., is capable of doing the proper job. The heads are heated close to 500°F; fitment is made for 0.005" to 0.006" interference-fit. There is NOTHING AT ALL wrong with using BMW seats.

7. Use of aftermarket one piece SS exhaust valves is a BAD idea ...especially if using BMW valve guides. BMW uses a high quality two-piece SS exhaust valve ....with the various parts materials selected for the best performance in the area being used. I do recommend aftermarket guides. I've noted that BMW seats are good, & aftermarket seats are OK if the proper type of material & properly fitted. SS ONE piece valves may swell up in the stems area, seize in that area, & stop rotation. Stems will gall, tulips & seats will deform. Sometimes the swelling is so bad with SS one-piece valves that they are not easily removable, & might drive your machinist nuts. Bottom line: One piece SS exhaust valves are NG ...do NOT use them. If you DO use them, be sure you match them to proper valve guide material. There is also the problem of the keeper slots at the valve tip as noted previously.

8. If your valve springs are not in good condition, & do not meet specifications ....& you use high rpm, you could have valve float, the valve could strike the piston & you will have a huge mess on your hands. There is a LOT MORE TO SETTING UP OF A TOP END .....this is just one mention of things that need to be checked ....including that the springs have proper force ....& do not bind up at full lift.

9. There are only a FEW experts on BMW valve gear problems & installing guides & seats, etc, that I trust:

Ted Porter at his Beemershop in Scotts Valley, California. NOTE that Ted has made a video about some of the lousy workmanship he sees coming from "automotive machine shops" doing BMW bike heads. I have permission to post the link here:

https://www.youtube.com/watch?v=R1rI3pog1DU

I suggest you watch that video! I think Ted has quit doing top ends.

"OAK" Okleshen in Richton Park, Chicago area. Oak died in 2017. He was the Guru's Guru.

Tom Cutter at his Rubber Chicken Racing Garage in Yardley, Pennsylvania (Tom uses Randy Long's services for the machine work ...Long's Mechanical Services, Honey Brook, PA).

Bud Provin at https://thenickwackettgarage.com/bmwtwin/ in Vermont.

By hearsay, I can recommend Bruno's, in Iron Bridge, Ontario, but he may have quit work, due to ill health.There is nothing wrong with ASKING any of them, or others, WHAT materials and techniques they use, ETC!

10. There are some that feel that a way around all these various problems is to use such as Black Diamond valves, & AMPCO 45 guides. I am NOT one of those persons.

11. Fuel requirements, Octane ratings, etc.: https://bmwmotorcycletech.info/fuelmiscl.htm

12. Milling (& less than normal valve clearance adjustability, etc.): It is rather common for heads to be milled, sometimes on both sides of a head, sometimes just one side of a head. The most common reason is warpage where the valve cover gasket fits. Unless the head is properly indexed & mounted, sometimes with shims (especially if previous work was done wrongly) to the milling table, the outer & inner surfaces might not end up being parallel. Further, a milling pass over the outer side can reduce the effective distance from head to engine case, & reduce the adjustment range of the adjuster cup-bolt that sets valve clearance. Shims may be needed to, effectively, move the rocker assembly outwards. SS shims to do this are available in metric sizes, such as 1 mm, from such as McMaster-Carr. They are INexpensive. Sometimes milling is done for the purpose of increasing compression ratio. This can also be done by turning the cylinder base properly ....or, a combination of both base and head, or just the head. I slightly prefer both be done.

13. Because these valve situations and comments are sometimes controversial, I thought it would be a good idea to offer input from someone BESIDES ME here. So, here it is, from a VERY experienced Airhead wrench, with a vast number of satisfied, happy, even thrilled customers ....who personally does (or, did) a lot of head work on Airheads. The following is very direct, to the point, brutally honest, and I believe totally trustworthy. This was the result of a thread on the Airheads List. This section is long, but I suggest you read it. The rest of MY valves article continues after this. I have done editing ONLY for minor ease in reading & such as for spacing & line length. I have one input, it is identified as from me. I have NOT corrected any spelling nor grammar. This, below, was from Ted Porter, http://www.beemershop.com.

"This is long so get comfortable if you're interested in my opinion....

A customer pointed me to this thread. I'm sorry to say I haven't had much time to be on the List lately, any of you who have visited the shop know how busy we can be. I was encouraged to respond due to my extensive history overhauling BMW heads and my experience with all the different valve, seat and guide materials that I've used over the decades. I've used all the stuff out there and over time have enjoyed the benefits of seeing those parts again many years and many miles later. I've been doing this work for a very long time with my own hands and eye balls, on BMW motorcycle heads exclusively, I thought my opinion might be useful. I wish I still believed in the BD valves. I was once a distributor of their product and a vocal promoter. It would benefit my business greatly to install BD valves because the factory is right up the road from my shop and it would be a hell of a lot easier for me to sell those products. I didn't decide to start importing valves from Germany because I like dealing with all the headaches associated with that process, but rather because that's how I get quality two piece exhaust valves on my shelves that meet my standards without having to pay $100.00+ per valve from BMW. The BD stainless one piece valves are much cheaper, have very nice profit margins, and you can order just a couple at a time and let Kibblewhite inventory the parts for you which

significantly lowers use of your capital. I believe many shops are compelled to use the product for these reasons. I was once a loud promoter of the product as well, however I started seeing some limitations and since overhauling heads is my industry, I did my homework by talking to the valve manufacturing experts here and overseas. There was definitely a consensus. To answer the OP question, BMW started using the two piece valve design many moons ago, long before the /5. For the exhaust valve it was determined that one material is better at the stem and the tip (steel) and a different material is better in the combustion chamber (stainless). It is more expensive to make the 2 piece exhaust valve but I agree with the engineers, there's a strong argument for the design. Note, this is only true with the exhaust valve. The intake valve is a one piece steel design (not stainless) and works without problems in that application due to the cooling effect of the intake charge.

I am not an engineer, but here is what the experts in this field explained to me:

1. The stem must be hard chromed so that it will wear well in the guide without material transfer and galling.

2. The tip must be hardened so it can be smacked by the rocker arm over many cycles without failure.

3. The keeper slots must be hardened to deal with the rotating design of the valve (the keepers do not grip the valve but merely secure the valve and upper spring cap by the grooves in the keepers and slots in the valve and allow the valve to spin. The rotating valve helps the seat and valve stay clean and makes them both last longer).

4. The valve face must deal with the high temperatures generated by the exhaust gasses.

Steel was selected for the stem because it can be "through hardened" at the tip and keeper slots, and the stem could be hard chromed. Stainless alloy was selected as the best material for the valve face in the combustion chamber. The two pieces are inertia welded together and every BMW motorcycle on the planet for the last 50+ years has this design. The two materials do not work well in the reverse roles. The stainless material is not well suited for the stem or tip. It is soft and cannot be through hardened, the keeper slots can fail, and the tip will not survive the pounding of the rocker arm, the steel of the stem would not work well under the heat stress of the exhaust valve face. Therefore it was determined that one material would not work well long term in both environments but, and here's the clincher, the one piece stainless valves are a hell of a lot cheaper.

The early one piece stainless valves we were experimenting with in the early 1980's developed well known problems. The early designs would not work well with rocker arms and required separate caps (known as lash caps) installed on the tips of the valves. The later designs were improved by welding a .060" thick stellite wafer on the tip to deal with the rocker arm contact.

Comment by Snowbum: BMW exhaust valves are through hardened at the tip/stem and do NOT need, nor do they have, Stellite wafers at the tips.

Regarding the growing concerns about keeper slot failures, we were told to grind the keepers so that the faces no longer made contact so that the valve would no longer rotate. I thought that was pretty lame and started looking for alternatives. The BD valves looked promising. We were told they solved the soft stainless problems through a process that hardens the surface of the valve and turns the valve black (hence the name) and by installing the stellite wafer on the tip of the valve. However the valve stem could not be hard chromed. I used these valves for many years, then I started seeing the problems; material transfer from the guide to the valve stem. We were told the galling problems were solved by the addition of a "dry film lubricant" impregnated in the stem, but inspection showed that the surface treatment would wear away. I still saw the galling and became concerned about seizure. Then we were told to try running wider clearances, which I thought was a poor solution. This is probably why some machine shops are now using cast iron guides to deal with the lack of hard chroming on the valve stem (although Kibblewhite suggests using their Ampco 45 silicon bronze guides). However cast iron does not shed heat well and it is softer then the modern manganese silicon bronze guides so I consider it a poor compromise. It finally became obvious that I was chasing my tale trying to sell a cheaper valve that would perform as well and be as durable as the two piece design and it became clear why the valve manufacturers who make valves for Audi, Porsche, Saab, BMW, M-B and so on are all using the inertia welded two piece exhaust valve.

For many shops the BD valve will become the default. They are waaaaay cheaper than buying valves from BMW or importing valves from Europe. Many of these shops also work on automotive heads, or they are multi-brand motorcycle machine shops. They are not so heavily invested in just BMW heads and it doesn't make sense to invest capital in the large minimum orders required to import valves from the manufacturers in Europe (my first order was financially painful). BD valves are the simple solution for many businesses, however in my experience and opinion, they are not the best solution for long term use in a street bike.

I looked at a pair of customer heads not too long ago that had been overhauled by one of those automotive machine shops turned BMW experts. The heads looked very pretty which makes many of you say, "just got my heads back and they looked great". What I saw was BD valves with over .003" clearance at the guide (probably to prevent galling) keeper halves no longer touching each other because they had been ground to prevent valve rotation and lower the risk of keeper slot failure, and seat eccentricity well over .005". Yeah they looked real pretty but the head work was crap. I asked the customer if he had been told that his keepers were going to be modified to stop the valves from rotating and he said no. I thought that kinda sucked. If you have stainless valves, have a look at your keepers where they sit in the spring cap at the tip of the valve just under your rocker arm, the two halves should be touching each other. If there is a gap, your keepers have been modified to grip the valve and prevent valve rotation so the keeper slots in the stainless valves don't fail. If anyone is interested in seeing an example of the keeper slot failure in a stainless valve I have a good photo to share.

To those of you that say "I have them in my bikes and no problems", for the vast majority of the heads I overhauled with BD valves in the 1990's there were no problems that the average rider would notice, but you have to look deeper. If you take them apart and inspect them with educated eyes and measuring tools, you will see the limitations. Sometime this manifests in a seized valve and the head popping off, other times your head work will just not last as long because there will be more wear in the guide, and again there is the keeper slot issue which still existed in the treated valve.

Problems with the stainless valves in street bike applications have been well documented. Perhaps some of you who've been around long enough remember the big article in the BMWMOA news magazine back before the internet about the heads popping off the stainless valves. I also believe someone named Kevin on this list created a website devoted to the problems he was having with his stainless valves, and there is also someone else on this list who sought out my opinion in the past who had similar stainless valve failures. Now it has come up again, this is pretty old news. Yes, I have seen the factory two piece design fail at the weld, but considering the sheer numbers of these valves in use, that percentage is extremely small. The number of one piece stainless valve failures that I have seen and heard about is exceedingly higher and there are far less of them in use. You do the math.

I'm not interested in an argument with any persons or shop using stainless valves, sell what you want to sell, that's your prerogative. My hope is that there is room on this list for another opinion from someone who is arguably the most experienced head rebuilder in this discussion. For those of you doing your homework, you now have my opinion to add to the mix.

Cheers,Valve seals, valve guides, valve springs:

Seals are not really needed on stock BMW valves and valve guides!

This section provides some information, but not recommendations!

1980's BMW 733/735 cars 11-34-1-273-501

Ones not requiring any machining ....for 8 mm only: FelPro, for the Opel 1600 cars.

The blue dot on the valve springs goes towards the head.

Take a look at Felpro SS70816, and use only the INTAKE ones.

I have heard that the design of these has changed, and they no longer fit properly, unless the guide is machined. Even then, the use was a stop-gap measure for those that installed SS one piece valves in BMW guides. That is highly recommended AGAINST.

NOTE! ...one piece SS EXHAUST valves, sold by some companies, do NOT match/mate properly with BMW valve guides, and besides the problems noted, above, you may have serious oil burning problems. Hence the use of the valve seals. These are not really needed, in my opinion, with a proper valve job with the proper parts.

BEAD BLASTING & HEAD CLEANING:

While many folks have gotten away with it, my personal opinion is that you should NOT dry bead blast heads (nor cylinder outsides) using the normal sand-type (glass beads) blasting materials, particularly at high pressures and the nozzle being close. Otherwise, no matter how carefully one masks & cleans up, small abrasive particles manage to get lodged in crevices or the metal surfaces, may come loose later & abrade cylinder walls, valve guides, pistons, etc, and get into the oil ....and the bearings. They may well IMBED themselves, doing considerable damage over time. If you simply must blast, use walnut shell or soda or CO2 blasting; which are less permanently abrasive. Vapor blasting with fine media seems OK. Vapor blasting is WET, slurry, media blasting. Heads (insides) are best cleaned by the typical owner by chemical methods ...it takes a week or so, but is SAFE!! The recommended cleaner is Gunk brand Hydroseal. Some are using strong solutions of Simple Green, which may eat into aluminum, but so far I have had no bad reports in overnight use in 1:2 mixtures with water.

Revisions:

01/26/2008: Incorporate all previous revisions & also move to article 60 sub-section 5; & update for clarity.

06/26/2008: Minor updating.

09/08/2008: " "

03/24/2009: Revised here and there for clarity.

04/16/2011: Update for valve noises, and add links to other articles of mine that are pertinent.

04/28/2011: Clarify a few details, clean up some wordiness. Were no errors corrected.

08/29/2011: Add section on Ted Porter's commentary from the Airheads LIST.

04/03/2012: Check over article. Clarify a few details. Clean up article a bit.

06/19/2012: Fix excessive use of fonts, colors, cleanup presentation.

10/15/2012: Add QR code, add language button, update Google Ad-Sense code.

03/02/2012: Add the two photos of top end damage, previously only on setvalves.htm; also make section separator lines all the same width and height.

2013: removed language button due to javascript problems.

06/25/2014: Added shims information

07/25/2014: Updated #5, to include oversize valves information.

12/22/2015: Clarify the reduction and banning of TEL, in the very early part of this long article. Update meta-codes. Increase left justification. Narrow the article. Remove links to outdated articles on such as gasoline additives. Minor updates and clarifications throughout. Increase font size. Update 100LL TEL additive amounts for today's aviation fuel.

03/28/2016: Add link to Ted Porter's video. Start process of updating meta codes, left justification, etc....won't get around to doing the rest for about a month.

04/26/2016: Update metacodes, layout, fonts, colors, details, ETC.

10/16/2016: Clarity on 1985+ models: that SOME 1985 & 1986 did not have the full fix to the valves/seats area.

01/11/2017: Metas, scripts, change non-standard red to standard color number, borders on photos, photos spacing, photos left wrapping of text to avoid some browsers displaying right side text wrapping. Go through entire article, code line by code line.

05/25/2017: Check over article. Minor colors and emphasis changes.

05/31/2018: Mostly cleanup.

06/19/2018: Add red text to clarify misunderstandings.

03/19/2021: Add hyperlink to Anton's article on the rockers

05/11/2012: Revise completely Noisy Valves and Preliminary Information for better clarity.

08/29/2022: Minor updating for better understanding.

01/10/2023: Minor updating to correct grammar, and clarify a few meanings, but only slightly. Slight improvements in explanations, 07/26/2023

© Copyright 2024, R. Fleischer

Last check/edit: Friday, July 05, 2024