SPARK PLUGS (Classic K bikes and Airheads)

How do they work? Theory and practice.

Spark plug threads, repairs, Helicoils.

Tightening torques. Gaps.

Antiseize compound ......or not?

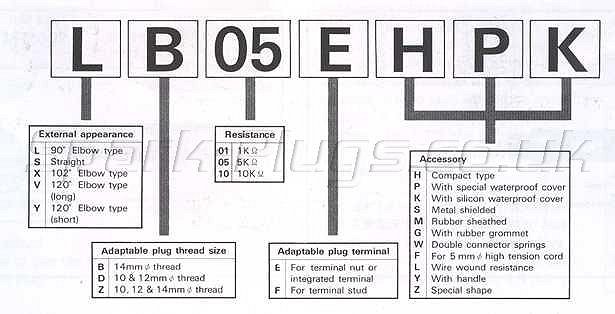

Spark plug caps.

Resistor & non-resistor spark plugs.

Heat-Range chart; equivalent numbers.

How do spark plugs work?

Spark plugs were invented a very long time ago. Most historians agree that the invention was in 1839; but first use in a gas engine was dated 1860. The basic design has not changed much since then.

A rather complete article is here: https://en.wikipedia.org/wiki/Spark_plug

A spark plug, with its insulation and metal places for a spark to jump between them, ignites the air-fuel mixture, after the mixture is compressed by the piston movement. The actual ignition of the mixture is by something called ionization. I'm going to avoid getting into that nerdy subject here. If you are curious about the subject, see near the end of this article: https://bmwmotorcycletech.info/nerdy-stuff.htm

A spark plug consists of a sort-of cylindrical body of metal (with a hex to enable use of a tubular or other wrench) ....with a hole through it. In this hole is a ceramic material used as a high voltage insulator, through which passes a small diameter metal rod with a threaded or other connection at one end and at the other end, that fits into the cylinder head, a slightly projecting tip. Electricity from an ignition coil is applied to the threaded or other connection end of the metal rod. The electricity has a very high voltage, such that even under the pressure of the gas-fuel mixture in the combustion chamber (with piston at or near top of the cylinder) a spark will jump from the rod (the central electrode) to a projection at the bottom of the spark plug metal body (called the ground electrode). Nearly all spark plugs have a ground electrode.

The white ceramic central insulator must become hot enough to allow such as oil and other contaminates to 'burn-off' during normal engine operation. If the ceramic insulator does not get hot enough, the insulator will accumulate contaminates which will carbonize and eventually conduct electricity and the spark plug will be 'shorted' (sometimes called 'fouling') and not deliver a proper spark. In the days of leaded gasoline, the lead in the fuel would slowly 'poison' the insulator, and that is why spark plugs did not last as long as they do today; and, it is a major reason that spark plugs were occasionally sandblasted in a special fixture, to clean off contaminants. Many modifications to spark plug design and to ignition circuits were made to try to overcome fouling problems and/or improve mixture ignition. Higher and higher powered ignitions were one of the methods used for improving mixture ignition, especially needed in more powerful engines, particularly as compression ratios increased more and more. Another factor was that, for less emissions and highest fuel mileage, the leanest mixtures possible were used....and such mixtures are harder to ignite, thus need higher power ignitions.

The temperature of the burning gas varies with throttle position, fuel richness or leanness, design of the camshaft that operates the valves, the compression ratio, and even the shape of the combustion chamber. For each engine design, there is an optimum spark plug 'heat range'. The "heat range" means that over a certain range of spark plug insulator temperatures, the spark plug will work properly, and not fail due to accumulating electrically conductive deposits; nor, fail through overheating the insulator. As a general rule, the major portion of the 'heat range' assigned to a specific spark plug model is a function of the length and width/shape of the internal portion of the white ceramic insulator and the shape of the surrounding metal. The longer the portion of the white insulating ceramic that is NOT in contact with the metal body of the spark plug (which transfers heat to the cylinder head), the hotter the spark plug insulator will be near the insulator tip during engine operation. A quite long insulator, non-metal contacting, means a 'hotter' plug.

Manufacturers of spark plugs use their own heat range, size, etc., identifications. Charts of equivalents, or near equivalents, are easy to find; a pertinent one is later in this article. In some numbering systems the spark plug identification is more informative than in others. For an example of a system of somewhat more informative numbering, The BOSCH W5 is a spark plug that runs cooler, than a Bosch W6, or W7, in the same engine. The reason a cooler spark plug might be used is because the gas temperature is likely higher, but there can be many factors possible, including the type of metal in the cylinder head (in our case, an aluminum alloy), where in the head the spark plug is located, ...perhaps a swirling motion of the incoming gases strikes the spark plug in a certain way, at a certain location....etc. The torque to which the spark plug is tightened will have an effect on heat transfer. As I mentioned previously, the main control over the spark plug heat range specification is the length of the portion of the white insulator inside the spark plug that does not contact the metal.

There are many hundreds of types of spark plugs. The threads vary in size and thread pitch, the spark plug hex varies in size, the heat ranges available are numerous.....and...there are many types of electrodes, ETC. For any given spark plug, there are spark plugs by other manufacturer's that fit & work almost (or exactly) the same. Some may cover a slightly different middle value of temperatures; or, a slightly different and wider or narrower effective heat range (even when charts say they are equivalent-to-xxxxxx). Generally, the charts are more than adequate enough. Popular equivalents to the Bosch spark plugs are available from such as the NGK brand, and there are numerous others. I caution you to not get 'sold' by advertising that promotes multiple grounding electrodes, etc. In many instances, such spark plugs will not work well in your motorcycle.

In general, the earlier Airheads (approximately before 1981 or so) had a higher effective compression ratio, and richer mixtures were used, and the mixture tended to burn a bit hotter and maybe a bit longer, due to the CR and to the jetting, etc. That was particularly so with the heavy use of throttle. The time it took to burn the mixture is also a factor, but that is way beyond the purposes of this article. Thus, for the earlier Airhead engines, a colder rated spark plug was required. You can also think of all this as the colder rated spark plug was needed as the engine power output was higher. Spark plug heat range values needed to be hotter for the later Airheads; thus, instead of W5, the engine may require W6 or W7; using an earlier generation numbering method for Bosch spark plugs. If the spark plug is 'too hot' rated, then damage to the spark plug could occur; or, the mixture could be ignited by the excessively hot spark plug BEFORE the spark occurred.

If you change the jetting in your carburetor, that may affect the spark plug needed. Sometimes on the Airheads LIST, and elsewhere's, you will see a recommendation for a slight change in needle clip position, or size of a jet, perhaps to improve engine performance. Usually the spark plug already specified will be OK. If the engine is modified for more horsepower, the spark plug heat range MAY have to be changed, usually to a 'colder' plug.

BMW specified a certain heat range for the spark plug in your engine, if it is stock, or nearly so. The recommendation will likely be accurate for normal use of the motorcycle. Serious problems can occur if radical changes in spark plugs and/or jetting are made.

The above photo shows three types of 'extended nose' spark plugs. All three have 3/4" reach, 14 mm threads. Extended nose means that the center white insulator extends beyond the end of the threads. Extended nose spark plugs are the only type that work properly in Airheads. The left-most spark plug is appropriate for Airheads; it has a single ground electrode and a standard size center electrode. The middle spark plug, Bosch XR7LDC, has two ground electrodes, & can be used in Classic K bikes. The XLR7DC spark plug with dual grounding electrodes, introduced during the K1200 production, also works well with prior K bikes. Classic K bikes can also use older numbered X5D, X5DC, XR5DC. The R in the part number means that there is a 'resistor' inside the spark plug. Resistor spark plugs are NOT recommended for Airheads. The right-most spark plug has even more ground electrodes, a gimmick that can cause misfiring, and should not be used in any engine.

Spark plugs are made with center electrodes of standard size, and also of 'fine wire' (much less diameter and often a bonded special metal). "Fine wire" spark plugs have no special need nor use in Airheads nor in Classic K bikes. The BMW combustion chamber designs tend to shroud the spark plug with the fuel-air mixture, hence this statement. Failure to heed my advice can result in occasional misfiring, even if not felt (but will reduce fuel mileage), ...or worse.

NOTE: If you have a Classic K-bike, and are using the XR7LDC spark plug, do not try to reset the spark plug gap, even when the spark plug is brand-new, .....as it is a special plug, and the gaps are preset, ....and would be difficult to change the gaps anyway without damaging the spark plug.

NOTE: This note applies to all vehicles, all engines. You can re-gap most single or dual ground electrode spark plugs when brand new, and never run, only. BMW says to not re-gap spark plugs. BMW did not explain that advice; and, BMW should have added this: ".....after they have been in use". That is what BMW means & I am in total agreement. After any spark plug has been "in use" the molecular structure of the bendable ground electrode changes. If you then try to re-gap the spark plug, you weaken the ground electrode. In rare instances they have broken off, causing engine damage. More often the insulator has been damaged during improper re-gapping, and that can create sharp hot spots which can cause serious combustion problems. Blast cleaning with hard particulates and re-gapping was very commonly done on old cars and bikes, especially with leaded fuels use. Done correctly, it is acceptable.

As miles accumulate, the electrodes erode, and the gap increases. Gap wear is usually acceptable until the gap becomes excessive, at which time marginal ignition systems or engines running very lean or very rich might begin to misfire, leading to poor fuel mileage. Fine wire tipped precious metal (center electrode) spark plugs are less likely to have this problem with advancing miles & the spark will find it easier to jump to the ground electrode, increasing the spark plug life, but fine wire spark plugs may not work well in some engines. I am OK with you trying them (but only if they have a single ground electrode, if used on Airheads).

The mileage it takes to get to a point where you may notice problems with the spark plug will vary considerably with a wide range of things such as spark plug heat range, cap resistance, actual mixture burning conditions, oil type and usage, type of ignition system, whether resistor spark plugs or not, amount of engine wear, etc. Spark plugs now last much longer, at a minimum doubled, due to the change to unleaded fuels. In the past, leaded fuels would eventually cause electrical shorts or leakage problems at the center insulator near or at the tip ...and it was common to replace spark plugs at 10K-20K miles; &/or, to clean them by 'sand' or other media blasting, & replace them at the next following service interval. Do not expect spark plugs on your BMW Airhead motorcycle to last as long as spark plugs on modern fuel injected cars, some of which are specified to last 100K miles before replacement. Cleaning/blasting of spark plugs on your Airhead should not be done unless you fully understand the process and do a thorough afterwards cleaning of all grit, and are willing to understand the ifs and buts. With a good-running Airhead engine, unleaded fuel, and a quality oil, etc., spark plugs MAY last 30,000 miles or so.

For the Airheads, worn gaps approaching even .040" are often still usable ...but spark plugs should be replaced sooner, especially if the grounding electrode gets quite thin (usually a thinned dished shape), as they will weaken. Decades ago some repairmen would file the ground electrode, sand-blast the plugs, set gaps, etc. With the change of labor rates versus cost of spark plugs over the years, and the rare spark plug failures, almost no one cleans plugs anymore. The gap can be checked, preferably with a wires-type of gap checker tool, but I recommend you do NOT adjust the gap. Check plug base metal color and appearance; check central insulator color and appearance. Replace the spark plug at reasonable intervals.

Spark plugs screw into cylinder head threaded holes. These male & female threads are exposed to combustion heat/pressure & also to byproducts and additives in the gasoline & oil. These additives tend to carbonize, & can accumulate in the threads. Combustion is not the same in all Airheads, some have a fair amount of burnt or carbonized oil, & other combustion products accumulating in the threads. Worn threads tend to accumulate more hard carbon. The carbon can act like an abrasive. It also can act like a cement!

If reinstalling a used spark plug, I like to clean the threads if the spark plug requires more than finger pressure to screw in (not including final torqueing). If the threads in the head have the look of excessive deposits I may go so far as to rotate the engine to open the exhaust valve, & blow compressed air into the intake area as I clean the threads (wearing protective goggles). A greased tap can work, but then you have to degrease the threads and I dislike that taps will tend to cut head metal, not just the carbon. I mostly use brass gun cleaning brushes, rotating them during cleaning. I've also seen brand-new spark plug threads that were not made well. Poor spark plug threads will damage the head threads. Poor spark plug threads have been identified on spark plugs made in various countries. A product called Color-Tune is reported to damage threads.

Aluminum cylinder heads can be damaged easily if one is not careful. There is a limit to abuse from over-tightening a spark plug, or removing & replacing a spark plug; this is even more so when the cylinder head spark plug threads are full of combustion byproducts & carbon. Carbon (from such as oil burning, or, the very bad use of oil or grease on the threads) can get very hard, & very abrasive. It can cause the spark plugs to injure the cylinder head threads during removal. It is not a good idea to put much torque on a spark plug when attempting a removal if found quite tight; in that case first try heating the cylinder head, as the head metal expansion may be enough to avoid damage. Running the engine for 3 minutes is a good way to do the large amount of necessary heating.

Some BMW motorcycles prior to the /5 series, I will just call them /2 bikes, had some metal alloy & casting problems, including soft alloys & voids. Even with very careful torqueing with the best antiseize compounds of the day, we still saw occasional problems.

I've seen poor metals & poor castings bring about failure of factory installed 'cast-in-place' steel threads inserts, & heat-cool cycling on those early inserts caused problems. For Airheads, the metal in the heads & the castings are very considerably better, but are aluminum, which won't take the abuse that steel inserts or cast iron heads will.

Many folks do not use torque wrenches, & some who do (and many who do not,) manage to over-torque spark plugs. I have seen someone over-torque a spark plug & he was using a torque wrench & it was set properly. His problem was not realizing that many clicker torque wrenches tend to be hard to detect the click if the setting is fairly low on the wrench's total capacity. This tends to be especially so on such as 100 maximum foot-pound wrenches which might have a rather subtle click when set low, say around 12 foot-pounds to 18 foot-pounds. Know your wrench. If you don't know what the click sounds/feels like at various settings, and/or are not all that familiar with torque wrenches, especially yours, then put the square end into your bench vise using soft jaws or protective metal, & test the feel required for various torque settings, that is, feel & listen for that click. Do this in the tightening direction. Cheap" beam-type torque wrenches (not meaning dial indicator commercial types) may be inaccurate ...& should not be used for critical items. Same caution for cheap tubular clickers. You can check the calibration close enough, yourself, see my articles on torque & torque wrenches.

Abused, the cylinder head spark plug hole threads will eventually start distorting ....& pulling out ...if they don't immediately rip out. While Helicoils or welding & re-machining, all do work OK, & can even be superior when done correctly, such repairs are usually avoidable if one takes some care in the first place.

I don't like to see extra places for sharp bits of carbon combustion products to adhere to. They create 'red-hot glowing places' in the cylinder heads from using inserts & can cause serious pre-ignition problems.

I recommend against Time-serts, which can change the spark plug heat value.

I have installed Helicoils, & also have welded up the spark plug thread areas & drilled & re-tapped them ...of course the heads have to come off for all that ...best to remove the head in any fix anyway ....although one can use the official Helicoil Spark Plug Thread repair kit, with well-greased parts, & with the exhaust valves open so you can blow chips out with an air hose. You can do a good job without removing the head, in most instances.

It is critical that drilling & tapping be done squarely. >>>>Absolutely and always use a drill guide & tap guide! MORE information on installing Helicoils, head on, or head off the engine, is later in this article.

DO NOT USE GRAPHITE PRODUCTS FOR COATING SPARK PLUG THREADS. A corrosive type of reaction is possible on the aluminum head.Anti-seize compounds (never use graphite products on steel going into aluminum):

The use of antiseize compound at spark plug threads is somewhat controversial, even among some experienced Airhead mechanics ...mostly I think this is due to some (not all!) spark plug manufacturer's literature; & perhaps some is due to misconceptions. Some is due to faulty belief in old-wives tales, ...or, possibly, bad experiences from those ham-fisted about torquing things. Yes, some professional wrenches are concerned about you, a non-pro, abusing things, & it is true that use of antiseize could (not will) make it somewhat easier for abuse.

Some manufacturer's, trying to play it safer (?) have, over many years, changed from recommending anti-seize, to not recommending it, or just ignoring the rather common use. An argument can be made for not using anti-seize, as someone not knowing the stuff was applied might then not compensate by reducing the required torque. I just cannot see any other argument against anti-seize use that is valid ...and I can provide a lot of reasons to use antiseize compound.

Karle Seyfert, an expert who writes for MOTOR, an automotive repair industry publication, had an extensive article in MOTOR in March 2013. That article, & some controversy & comments by one well-known 'guru' in the BMW motorcycle repair business, at approximately that time on an Internet mailing list, prompted me to add more commentary to this part of the article you are reading. I have not changed my own practice, intent, nor recommendations. I will give you information on what/why automobile manufacturer's and some spark plug manufacturer's are publishing/recommending!

Some experienced mechanics believe that if antiseize is used it is 'easier' to over-torque & damage threads. That is true, but it is true only if the person is not adjusting torque lower, to compensate for the use of anti-seize compound; or, just being more ham-fisted; or, not using a torque-wrench. Another reason is that many engine makers have the torque specifications on the high side of what they should really be, particularly for aluminum cylinder heads. Sometimes gross errors in publications from long long ago were carried over, and never checked.

It is my strong belief that you should be using a torque wrench; and, lower the official torque value (which is without antiseize compound unless specifically so-stated). I believe the factory torque settings (some, anyway) are too high ...even if anti-seize compound is not used, or never has been, on the engine.

Since popular anti-seize compounds act like a lubricant, the applied torque (if the book value means no antiseize) must be reduced ...by about 15% is typically correct for spark plugs into aluminum. For Airheads, that use 3/4" reach 14 mm threaded spark plugs, this percentage is to be applied to original published values of ~16-18 ftlbs, to be reduced by the percentage shown. That means that the torque wrench should be set for ~13.6-15.3 ftlbs.

NOTE! Some are using 12 mm x 1/2" reach spark plugs, for the bottom plug with dual-plugged heads, with antiseize compound.

The total thread surface area is so small, AND, using anti-seize, one must be cautious on the amount of torque. Normally, a 12 mm plug is torqued to about 20 ftlbs maximum, but that is in cast iron. I'd gently torque to about 8, and then for 'feel'. Probably you will end up at about 10 to 12 ftlbs. You will likely find that this is about the same as ¼ to 3/8 turn from just contacting. See my dual plugging article for more information, such as for 14 mm plugs, 3/4" reach, etc.

Some types of spark plugs, such as taper seat types (not used on Airheads), are not supposed to be used with regular anti-seize compounds, as they are degree-tightened & so the manufacturer typically makes a blanket statement not to use anti-seize compounds, applying to all their spark plugs, rather than providing full information which is more complicated. Other manufacturers say OK, & give the needed lower torque values. Some manufacturer's do not mention use of anti-seize at all, & some say you must use it!

Some manufacturer's say they are concerned with heat conduction; that the heat range of the spark plug is or could be changed by the use of anti-seize compound. That is possible, particularly if the torque used is not correct, but with torque being reasonable, at worst case the effect is quite small, otherwise none, & even that would very seldom happen, and would have no effect on your BMW engine ...& I believe any such concerns should be ignored. What those manufacturer's do not tell you is that their biggest concerns are for considerably loose spark plugs. I have not seen any problem in real life situations if the torque is set close to proper. I tested for this, with various torques & test runs on a bike, reading the spark plugs, and it took a substantial amount of torque decrease to increase the spark plug heating, and for overtorquing there was no change at all. Loosening did not happen with reasonable torque values.

I have always used some sort of anti-seize compound on my own various bikes' spark plugs. I have over 650,000 miles on just my own BMW's. I used it on my customer's bikes, and on other engines besides BMW. No problems, ever!

I am in favor of using anti-seize compound on spark plug threads. I believe that if official torque values are reduced (assuming originally specified without anti-seize compound), & you use the anti-seize compound, you are less likely to have pulled thread problems, heat range will be more consistent, & there will be less problems with hard particles of carbon that deposit themselves into the cylinder head threads, which otherwise can cause excessive wear every time you R/R a spark plug.

Antiseize compounds vary in characteristics, but I have found that all commonly available ones that I have tested, which includes the silvery colored Permatex anti-seize commonly found at autoparts stores, are OK. Caution: Using oil or WD40 will eventually result in hard carbon deposits in the threads, & thus tend to accelerate wear of the threads & tend to change the effective torque. Do not use oil or WD40! NOTE that just because an antiseize compound is silvery in appearance does NOT mean it does NOT contain copper .....most DO contain copper.

What do the manufacturer's say; what are some problems seen, etc. :

Some manufacturer's recommend "penetrating oil" for tight plugs during removal. Most fail to tell you to very thoroughly remove that oil before installing a new spark plug. It is also not easy to get penetrating oil into the spark plug threads with the head on the engine ...but if you can safely unscrew the spark plug some, then you can use such a very thin oil with the head in place. A mixture of acetone & automatic transmission oil, ~50-50, works better than all the penetrating oils many of us have tested!

Once anti-seize compound is ever used, it tends to work its way into the aluminum head metal. From that point on, it is best to always use anti-seize compound. Do not use graphite types as they can cause corrosion problems.

Some manuals, such as later Clymers, etc., may tell you to put a dab of anti-seize compound (often specifying aluminum type) on the spark plug threads before installation; but, these books may forget to tell you to reduce the torque. I suggest antiseize containing nickel and copper.

Some spark plugs seem to have a bit less diameter or other irregularities with the threads that can promote carbon or wear. Thread & quality control problems have been reported on Champion & other spark plugs. It has been reported even on Bosch plugs, if not made in Germany. Overall, German Bosch tolerances seem to be best. NGK makes a good product & I have never seen a problem with NGK plug manufacturing. Bosch may plate the threads, which helps avoid use of anti-seize, if you are so inclined; but, usually is needed if again removed and returned. NGK plates some spark plug bodies, & on some threads, that they put on a coating or special treatment; see below. I still use anti-seize on all spark plugs with standard non-tapered seats.

****The latest NGK literature specifically mentions using anti-seize compound, in that it should be used on their non-plated plugs. As I noted above, I use it on all spark plugs for BMW motorcycle engines. I strongly suggest using antiseize if that particular spark plug is ever removed and reinstalled.

If you were to access the factory repair manuals for many bikes & cars, you would find that they are not consistent with use of anti-seize compound at the spark plugs. Some say you must, some don't say anything, some say you must not. I've already mentioned some of this, & regarding taper seat plugs, etc. Now, we get into this more deeply:

2010 Honda Pilot: Honda says to apply antiseize compound.

2007 Subaru Legacy: gives a torque rating 'without oil on the spark plugs, new plugs'. If lubricated (does not specify type of lubricant) they say to reduce torque by 'approxmately 1/3 of that specified' to 'avoid overstressing'.

Chevy Cobalt says not to use antiseize ....because if you do, you will damage the cylinder head if you overtorque. Chevrolet does not mention that overtorquing anyplace is likely to cause damage.

Service information for many vehicles not mentioned here were checked. BMW cars, Cadillac, Dodge, Ford, Hyundai, Mazda, Mercedes-Benz, Porsche, Toyota, VW, Volvo. All these gave specific information on torque, but none mentioned anti-seize. I could, obviously, not check for every model, every year ...but, I looked at numerous relatively late model vehicles, & while I did look at older cast iron head engine vehicles, I concentrated on aluminum heads. BMW, motorcycle division, is surprisingly quiet.

NGK, the spark plug manufacturer, gives the strongest advice against using anti-seize ...but, in a way, they also at the same time give very strong advice about why you should use anti-seize ....at least on their spark plugs. They have an entire technical bulletin on the subject. Condensing that bulletin for you, ... they do not want the compound used on plated plugs (in one place they say all their plugs are like that now ...not true, but good enough), & then they say not to use anti-seize compound on initial installation. Then they stop talking about it, & confusingly say that all their plugs are coated with 'special trivalent zinc-chromate shell plating' which is designed to prevent both corrosion & seizure, eliminating need for compounds or lubricants. They do not separate threads from the body in the discussion, but it can be implied from the prior sentence.

****You must read what NGK says & how, very carefully; ....because, apparently, NGK does not want anyone to remove a spark plug unless a new one is then installed. Yes, no reusing of a spark plug even if only removed for inspection!

****NGK makes it difficult to get the information, but here is their information, in my words. Read this very carefully: If you insist on re-installing an NGK spark plug, even if never actually having run the engine, you must use anti-seize compound. ... Because: Once you unscrew the plug, the NGK super-thin 'plating' coating is, in essence, partially removed permanently, each time R/R removes more, & the plug can then have galling & other problems. NGK says nothing directly about what happens to that plating coating, which is another story entirely. It could be damage-causing, or; well, anything. There is simply no further information. It is my belief that installing and removing the spark plug simply does, by friction in the threads, remove much of the super-thin-"plated" coating that NGK applied.

Autolite (another major supplier) spark plug sales information says its plugs are nickel-plated, & says anti-seize compounds 'can have a torque multiplying effect...'....but then says nothing else. However, engineering books from Autolite say things that contradict its other books' information, & says you must use a thin-film coating of high-temperature nickel anti-seize ...and specifies, specifically, certain plugs & problems that occur when this is not done ....in particular the long reach HT plugs (used on Ford 3 valve modular engines, etc ...that have well-known plug removal problems).

There is considerably more to all the above things about anti-seize compound; which I abbreviated, so as to not bore you too much.

My advice: Do use anti-seize compound, and use my recommended reduced torque values. Look at the proper book information. BMW has had various torques, for the same 3/4 reach 14 mm plugs. More later, herein.

I am fine with you using nickel type or copper type of anti-seize compounds. Most anti-seize compounds contain one or the other or both, & do not specify except in engineering-sheets. They likely have copper (even if silvery in color), but don't say (which contradicts what a certain foul-mouthed maker of videos for BMW bike repairs says in his videos ....about a must to use a certain copper product).

Do not use graphite products, including graphite-based antiseize compounds, for coating spark plug threads. A corrosive type of reaction is possible on the aluminum head. That advice extends to any steel part attached-to, or threaded-into, aluminum alloys. Graphite containing anti-seize products are popular with plumbers, for plumbing, only.

Amount of torque to use when installing spark plugs:

1. You can, but should not, tighten spark plugs by hand without using a torque wrench, even after you have a good feel for it. I recommend you always use a torque wrench! I triply recommend it for bottom 1/2" reach spark plugs on dual-plugged modified Airheads! In a field situation, I would do it by hand, carefully, if I did not have a torque wrench available.

2. I've seen various forces needed to properly seat spark plug crush rings, because crush rings vary in how they are made and some are not easily removable from the spark plugs, and some folks are just lazy or cheeeeep ....so many folks don't remove and replace them. Contrary to many books and some advice by others, I am OK with not replacing the semi-captive type crush rings, if they are in good condition, & if you use a torque wrench! Many books say 1/2 turn on new crush rings after the spark plug just barely is seated, amounts to proper seating to the head & crush ring; & they may also say 1/4 or 1/3 turn on used ...or new...crush rings. I say, do not depend, nor do, any of that! I recommend against those practices for any modern engine unless specified by the factory, OR, just be cautious. DO NOT DO ANY TURNS OR FRACTIONAL TURNS METHOD ON AIRHEADS OR K BIKES, unless you KNOW what you are doing.

3. I STRONGLY suggest that you use a torque wrench. Keep in mind that not only do you not want threads pulled, but you also want to maintain the rated spark plug heat value specification; etc.

4. What about BMW's own torque values for spark plugs? They have varied over the years, but BMW wisely, finally, after decades, updated the torque values in the owners booklets, etc. The value is 25 Nm, +-3. BMW did not specify, but that is for no anti-seize compound being used. I DO THINK THAT THE 25 Nm VALUE IS TOO HIGH. I suggest that if you previously used BMW's 25 Nm +-3 value, and then do use antiseize compound, then do reduce the torque to 20Nm. Note that 25 Nm is 18.4 ftlbs; and 20 Nm is 15 ftlbs.

The torque values I supply below are generally safe values, with new or used crush washers/rings ...when used with a drop or two of anti-seize compound spread thinly onto the clean spark plug threads (fingertip, or you can push the stuff very thinly into the threads using an old toothbrush). Do not get anti-seize compound onto the area of the end of the spark plug, nor have any on the exterior insulator...it will conduct electricity.

3/4" reach, 14 mm, used as top spark plugs, about 14-15 ftlbs. This is the stock top spark plug size for Airheads.

1/2" reach, 14 mm, about 12-14 ft lbs. This is a commonly used bottom spark plug size on dual-plug conversions. This torque value is usually but not always enough to fully seat the particular washer and spark plug. You don't want the plug loose ...if it loosens and rattles out, that pulls/wears threads. Some have installed smaller thread diameter (10 mm or 12 mm) spark plugs for the lower plugs. I've had good results with 8-12 ftlbs for those.

Dual Plugging information:

This paragraph assumes you are using anti-seize on the spark plug threads. Some have installed, for the lower spark plug in dual-plugged installations, a custom made thick aluminum spacer/washer that is welded, all around, to the head. Some just use such a spacer without welding. The washer may be threaded if welded, or may not be, if just used as a spacer. Some may have welded up the actual head material to be thicker, then drilled and threaded it. The reason for these various things is that the lower head area does not have enough aluminum thickness to use the 3/4" reach type of spark plug (3/4" reach is used, stock, on the top spark plugs) without doing something; and, the 3/4" spark plug is too long and would stick inside the head too much anyway. The result of using a 1/4" spacer, threaded, welded, or not, whatever.....is that the top & bottom spark plugs can both be 3/4" reach. If you did not do something like these things, then your only choice is a 1/2" reach spark plug. If you have installed a welded or not welded washer (1/4" thick), unthreaded, and are using a 3/4" reach spark plug, then use torque value of 12-14 ftlbs. If you have welded up the area, by adding material, or welded a ~1/4" washer to the area, and threaded from the inside to outside, so the threads are continuous and proper, covering the entire hole/washer/weld, ....then use my recommended 14-15 ftlbs. Remember, this is with anti-seize compound in use.

5. One is supposed to, in most considerably older literature, use a brand-new crush washer each time a plug is removed & replaced, but we all know that most of you won't, & many plugs have the washers fairly well captive & finding new crush washers is often frustrating. Just be careful about torque. Many years ago it was common for mechanics to install a fresh washer each time, and tighten with a common tubular wrench, not a torque wrench, and tighten until the crush washer was felt to crush & seat; & then increase a certain number of degrees; or by feel. That was done on cast iron heads. This can still be done on aluminum heads if you have a quite decent feel for it, but it is more dangerous to do it on aluminum heads. Do use a small amount of antiseize, torque wrench, & proper torque.

6. What about installing clean and dry (No anti-seize compound)?? With no anti-seize 'ever' used on your heads, or exceptionally clean threads, you can torque to 18 ftlbs on the top plugs. If you have the 1/2" reach 14 mm bottom plugs, you can go towards 15 ftlbs.

18 ftlbs maximum for clean & dry threads is my personal limit for 3/4" reach plugs, which are the standard top plugs for Airheads. Clean & dry here, means no antiseize; or, none visible with a careful look-see. If any question if antiseize was previously used, then use a lower setting. Here is information from the official BMW Service Information sheet for the late Airheads; this is the torque value to set per BMW:

18.4 ftlbs (3/4" reach standard spark plugs). Don't use that high a figure for threads with anti-seize compound, and I consider it an absolute maximum for no-antiseize-compound installations.

The latest Bosch manuals, for 14 mm threads spark plugs in both aluminum & cast iron heads, recommend 7-15 ft lbs. That is not oiled nor using antiseize compound. Unfortunately, no information about the thread length is given. MY opinion is that 7 is much too low. Best you follow my advice given earlier.

Quite some years ago it was common was to see 14 mm spark plugs specified in plug manuals at 26-30 ftlbs (!!!) in cast iron; 18-22 ftlbs in aluminum. No allowance for short or longer thread types was usually shown. Do not use such values! ...You will ruin the threads in the aluminum alloy head!

Removing spark plugs. Repairing spark plug hole threads:

It is not uncommon to see damaged spark plug threaded holes in cylinder heads. This comes from excessive torque, dirty carboned threads, etc. If the threads are in need of repair, you may ....or may not ....be able to 'reform' them, without installing a Helicoil. Some experience & inspection with #1 eyeball, should tell you yes or no. This can be done carefully with a good tap, but remember to lubricate the tap (I use white lead), and the goal is to reform, not cut.

When trying to remove a spark plug, if you find a spark plugs that, upon some loosening, seems to tighten up appreciably, STOP!!

Avoid thread damage!! Use a lubricating penetrant. A homemade 50-50 mixture of ATF in acetone really is better than commercial penetrating oil products. Apply the mixture several times at the junction of spark plug and head. Allow to soak, even overnight if need be; & then remove the spark plug carefully to avoid damaging the threads. This means, sometimes, using a tighten-loosen-tighten-loosen approach using more penetrant. You will be initially using the penetrant without removing the head, but be careful, do not damage the threads by using too much removal torque ...take your time. I will usually heat up the head (running the engine is best for this), and then try spark plug removal with any, or additional penetrant mixture. If the spark plug will not smoothly remove without damaging the threads, then it is your choice whether to remove the spark plug head on, or head off. Snowbum will usually heats the head to a MINIMUM of a decent sizzle temperature by running the engine, or the head in his oven, and if no luck, then I will go to 300°F, which usually works.

How to clean up, prepare, and repair damaged spark plug cylinder head threads, with the head being left in place on the engine:

(if just carboned, try using rotary motion on a shotgun cleaning brush in both directions)

To prevent any chips from getting into the cylinder, there are various ways. These include using a lot of grease on the tap (my method). Another method 'talked about' is filling the cylinder with shaving cream (messy ...& must be cleaned out later, and I'd say more, but want to be polite); using a vacuum cleaner in reverse to pressurize the cylinder from the intake with the exhaust valve open ...or, a combination of things. I use ONLY the grease method as I have found it works very well, with no drawbacks.

If you are installing a Helicoil with the head still on the cylinder, I suggest you use the grease-the-tap method & if you want-to, add the air pressure method, both at the same time ....& wear eye protection. Note that it is critical that the threads be 100% degreased before installing the Helicoil, & the Helicoil may be locked in place by using Loctite red during its installation (do not forget to have the Helicoil below the surfaces!). Allow the quite strong red Loctite to fully cure for a couple of days, then clean the threads again, and again quite thoroughly, with a strong solvent, such as acetone or MEK, and a brush, ...and again before installing the spark plug. Treat the spark plug threads with a sparse amount of anti-seize compound. Properly done, the repair is stronger than original, and you can consider safely using the high side of the antiseized threads recommended torque. Do not forget these steps of cleaning off the excess uncured Loctite! ...You do not want to Loctite your spark plugs into the Helicoil! The heads get very hot & Loctite only gives a small amount of holding power when the head is hot, but it does help. You should use a grade of Loctite specified for use at highest temperatures. For the latest part numbers, see: https://bmwmotorcycletech.info/chemicalsetc.htm. In an emergency situation, or if you don't want to wait a day or more for the full Loctite cure, ...just clean the threads & install the Helicoil, & ride away. I recommend the full cure. To speed up the cure, there are Locquik liquids to treat the surfaces first; but I usually just warm the head, as that speeds up the cure.

It is very important to have a guide machined or purchased to allow exactly 90° drilling & a guide machined or purchased for the tap. Guides ensure, if you use things properly, that your hole & threads are dead square to the surface. Tap handles often have a centering recess in one end, helpful with some jobs that can lay flat. If the heads are off the bike you can use that handle feature in your drill press, with the head carefully positioned and clamp to the drill press table. Done correctly, you do not need the guides if done on a drill press.

Here is a method to try if the threads are not too bad:

((I have also used this method when having to drill, thread, & Helicoiling, or, just reforming original threads))

Be sure the piston is not too near being fully outwards. When doing threads or Helicoil work, be sure to have the piston down from TDC (down from OT mark on flywheel), enough so that drills, taps, etc., will not strike the piston. Do not go too far with this, or there will be lots more volume which takes too much air movement to blow out the chips.

Take a small piece of cloth (I prefer Turkish toweling), & roll it up to fit moderately tightly in the spark plug hole. Soak in a slow evaporating penetrant, let sit overnight. The next day, use a shotgun cleaning brass brush with a solvent to clean the threads; rotating both right and left and then left to back out the cloth or brush, carrying the debris. Then use a good fresh sharp 14 mm tap that is quite well heavily greased. You can use white lead grease too, even anti-seize compound. Be generous with the substance, you want it to also capture metal particles, not just act as a lubricant. Keep the tap quite square to the surface, using a guide if needed. Back the tap out often, cleaning and reforming a few threads at a time, wiping off the tap and adding grease as necessary. In many instances the tap will reform the threads, rather than cut them (it may do both). I then thoroughly clean the threads, leaving the threads clean & dry. Then I put a dab of anti-seize ...not much ... on the first 4 threads of the spark plug, measured from the spark plug electrodes end, before installing the new spark plug. I then torque properly. Do not spread a lot of anti-seize onto plug threads. You want to totally avoid getting any on the ceramic tip area, where it will electrically short-circuit the spark plug. Wipe off any anti-seize you got onto the exterior white ceramic portion.

NOTE! ....If using the air flow pressure method to the intake port to blow out any chips, be sure to wear eye protection ...any nasty sharp chips could be flying out the spark plug hole. For that method, the piston should be set so the exhaust valve is also open, so debris comes out the exhaust system as well as the spark plug hole.

Resistor caps and resistor spark plugs:

I do NOT recommend resistor type spark plugs, from any manufacturer, for BMW Airhead motorcycles. While 'resistor' plugs or resistor caps or resistor wire, reduce the current, thereby reducing Radio Frequency Interference (RFI), and also reduce gap erosion, the use of resistor spark plugs in Airheads is not a good idea. The use of the stock resistor CAPS is acceptable, necessary on the 1981+ models; and recommended for the pre-1981 models. I prefer 1000 ohm caps for all pre-1981Airheads with stock ignition systems (points) and similarly 1000 ohm caps for points ignitions that have 'points boosters. Early points models Airheads had nominal 1000 ohm caps, and later points Airheads had nominal 5000 ohm caps. I prefer the nominal 1000 ohm caps for all points models.

From 1981, BMW used an electronic ignition. Nominal 5000 ohm spark plug caps are a MUST on those, to protect the ignition system.

Some types of radio frequency interference (RFI) can affect other things, such as electronic ignitions & electronic tachometers, sometimes in strange ways. I do not recommend zero ohms caps; but they are usually usable, on pre-1981 Airheads. 1000 ohm caps should not be used in anything but points ignition in our Airhead motorcycles. I do not recommend resistance wire, EVER. In Airheads, resistance in the plug caps has several functions ...here are a few ...with more following this paragraph.

(1) Reduce the erosion (wear) of the electrodes in the spark plugs.

(2) Reduce RFI to surrounding vehicles.

(3) Reduce RFI being conducted into the motorcycle wiring & thereby getting to the Hall transistor in the canister on 1981+ models ....it can destroy that transistor.

(4) Interference with the tachometer.

(5) You will find some of the same cautions for various reasons with such as the Boyer Microdigital ignition, etc.

It is possible that added spark plug resistance (in the plug or cap) can slightly increase the length of time the spark ionization effect lasts, allowing better igniting of the fuel-air mixture, up to a point, & also possible that then the energy level during part of the striking arc falls off, & performance suffers. There are arguments against that theory of spark (plasma) duration; and, if any, the current reduction may be said to offset it. For all this theorizing one gets into electrical spark characteristics in some complicated ways, so I won't go further with any of that here. I also will not get into any discussion dealing with resistors upsetting the relationship between specified coil secondary resistance and other coil characteristics, and the spark. I'll spare you all that theory, etc., although I will make brief mention of it here, & below.

There can be real problems with spark plugs that contain "resistors that are not". Some of these resistors (in resistor type spark plugs) are really not pure resistors, but are LOW resistance coils, acting like an electronic part often called a choke (real name: inductor). It is possible they can damage or otherwise upset the 1981+ ignitions (and even the tachometer) for complex reasons. Re-said, some 'resistor' spark plugs are not true resistor plugs ...they have a small coil of wire which reduces RFI by acting as an electronic 'choke' (inductor), and may be so manufactured to incorporate a capacitance effect as well. The electronic ignition (and even the electronic tachometer) may not like them. That same sort of thing was done with spiral-wrapped-metal-core ignition wire ....sold as Suppression Wire ...where it was not really resistance suppression wire. You can measure the plug, cap, or wires if curious ....with an ohmmeter. The actual igniting of the fuel-air mixture in the cylinder is initiated by a plasma (ionization), ...and then the spark occurs. Use of inductances has an effect on the initialization, in ways too complicated ways to get into here. You can easily determine what type of basic internal spark plug 'resistor' you have by measuring the top connection to the center electrode, using an ohmmeter. Yes, there are some spark plugs that are a combination of resistor, etc., but they won't be a problem.

Expanding on earlier information:

Spark plug cap nominal values are 1000 ohms on early two-coil model Airheads (usually thought of as prior to 1979) that had points ignition. Later points bikes used 5000 ohm caps, but 1000 is OK to use for any points model Airhead. BMW shipped 5000 ohm caps on some motorcycles before 1979. A change on only points models, from 5000 back to 1000 ohms might give some extra ignition performance in the highest rpm area ...near redline+- .....& possibly help in starting in cold weather & in other marginal situations, including old oil burning engines. Use only the nominal value 5000 ohm caps on the electronics ignition models (1981+).

Cautions: The spark plug cap with its resistor does everything the pure resistor versions of resistor spark plugs do ....without the danger of injuring the 1981+ ignition by forgetting to use the resistor plugs if you decided to use the stock non-resistor caps. Don't use carbon resistor cables like cars sometimes do ...they can give intermittent problems on Airheads. If you install both resistor plugs & resistor caps, your spark can become too weak to reliably fire the mixture 100% of the time, particularly in later leaner-running Airheads. This has been seen with 5,000 ohm caps & resistor spark plugs being used at the same time.

I am aware that BMW used both resistor caps and resistor spark plugs on some Classic K bikes ...but, the original specification was resistor caps only. I suspect BMW changed to resistor spark plugs (and did not use 10,000 ohm caps but kept the 5,000 ohm caps for keeping the parts simple), to further reduce radiated radio interference; as the K bikes were offered with radios. I suspect that it might also have been done to reduce the inductive and capacitive effects that having the ignition wires bundled together, in very close proximity, as they enter the cylinder head metal channel area all together. I do not know the specific problems BMW thought were possible, it could be anything from cross-firing to interference with such as the speedometer, odometer, or other electronics, including the ignition itself. Certainly there are some unknowns, INCLUDING the question of why the K75 has an on-purpose spark gap built into the spark plug wires. I would love to know the real, true, engineering reasons for that! On Classic K bikes I recommend resistor caps, & not resistor plugs, although resistor plugs and caps, together, may seem to work OK ....until something gets marginal!

The 1981+ Airhead motorcycles have considerably more energy coming from the coil(s), & are designed for 5000 ohm caps ...BUT anything under a measured 2500 ohms+- is likely to damage the ignition on these 1981+ models. Do not misconstrue my words here. For the electronic ignition models, I recommend the 5K caps & that you do not use resistor plugs! ...although you may (or may not!) get away with using both without a degradation in performance. Do not use 1000 ohm or zero ohm spark plug caps on 1981+ electronic ignition Airheads as you may risk damaging the ignition system, and the damage may not show up immediately.

Bosch spark plug problems...or potential problems:

First Problem:Second Problem:

Bosch told me that the nominal value for the resistors in their resistor plugs is going to be 2000 to 6000 ohms. Below ~2200 (and possibly a bit higher) is not safe for the BMW 1981+ ignition, as determined by Airhead Guru "Oak". At this time I can not recommend, & in fact I specifically caution against, using Bosch "resistor" plugs in 1981+ models, or any models you have converted to electronic ignition ...unless you retain the proper 5000 ohm BMW resistor spark plug CAPS, or NGK 5000 ohm caps. I do not like to see resistor plugs at all in Airheads.

Third problem:

Bosch ...purposely, or accidentally, ...sometimes ...put resistor plugs in the older small cardboard boxes with wrong printing. If you purchase a Bosch spark plug (they do make quality plugs! ...at least the German made ones), check the box contents ...AND read the number off the plug metal body itself, do not depend on the box numbers! Frankly, I would also use an ohmmeter!

Fourth problem:

Bosch (and, NGK too, for that matter) has gone to a 4 digit part number for spark plugs. There is no good way for you to tell if the plug is a resistor type, or not, from just that number, unless you know what the number means ....resistor type ....or not. The plug might have that number or an old number on the metal body. There is more on box problems later in this article! Your BMW bike dealership, if it orders plugs from BMW, MAY have the non-resistor plugs, & with the old part numbers on them ....but, check to be sure. I am not going to try to keep up with it all anymore. Just look at the markings on the spark plug metal body. No "R" allowed in the part number if it is a conventional old-style Bosch number. You can also use an ohmmeter.

Bosch sales (and perhaps other Bosch folks) may tell you that their resistor spark plugs are fine in engines that called for non-resistor plugs. I suggest you should not believe them for YOUR engine.

Miscl. notes ....and a bit more depth on some things:

Non-projected nose spark plugs may foul and/or misfire when used in Airheads. You might not feel it or hear it, but fuel mileage will decrease. Using spark plugs that have an extended nose/tip is important for proper combustion on an Airhead and classic K bike engine.

Platinum or other precious metal tipped thin electrode spark plugs, very especially with more than one surrounding ground electrode, are a waste of money, particularly on Airheads, & may not give reliable ignition ...they can occasionally misfire & even if you don't feel it in engine performance, so they too can waste fuel. There is some indication that these 'fine electrode' plugs are not as good as the stock types. Of course, this is contrary to manufacturer's advertising ...nothing new about this sort of thing.

BMW did engineering work to ensure that the incoming fuel-air charge is swirled & passes by the spark plug in a specific manner. Save your money, do not buy specialty spark plugs. Avoid specialty dual, triple, or forked, and other similar special electrode(s) plugs. Don't try to get more spark plug life by using special spark plugs of the type that have forked ground electrodes, more grounding electrodes, and fine wire or precious metal tipped center electrodes. You will be replacing your spark plugs often enough, that the lower metal erosion wear on certain specialty plugs is not any advantage. Wasting fuel by using the wrong spark plugs can pay for a lot of spark plugs. With today's unleaded fuels, spark plugs last a lot longer, usually at least double the old 15,000 miles we all expected to replace the plugs at using leaded fuels. Yes, I have seen plugs last much longer than 30K on Airheads, and especially K bikes.

I am not against all fancy new-fangled spark plugs ...but, I don't want to be considered as promoting them unless they have real value. For an example, the latest NGK Iridium spark plugs are constructed with a double shelf, or call it a tiny step in the side of the central ceramic insulator, near the tip end. This offers a secondary spark area, that also cleans, or helps clean, the center area. Preliminary tests seem to confirm NGK's claims to some extent. I have yet to do dyno tests on any BMW bike with this type plug. So far, no misfiring that I can figure out from the plug and a portable oscilloscope, and performance is at least equal to the stock plug. This might end up being one specialty spark plug worth the use of ....for some situations. It might even end up as stock standard construction.

I am not against all precious metal (iridium, platinum...) fine wire spark plugs. Some have real value on engines designed for them; AND, they can be put to good use on industrial constant running engines that don't have the spark plugs replaced very often; and/or, that have special ignitions. Decades ago there were almost no such ignitions, & the usage of long lasting precious metal center electrode spark plugs was for industrial pumping engines, etc. More recently, especially in the nineties & to the present, many cars have manufacturer's recommend plug changes as late as 100K miles. This is primarily due to the use of UNleaded fuels, & the exceptionally more complete burning of the fuel in modern fuel injected engines, coupled with cleaner burning (fewer deposits) oils and fuels. Many modern cars run at higher rpm (or, higher combustion compression), may have more sparks per mile, & many use very high powered ignition systems which can be harder on spark plug electrodes; old type electrodes could erode away faster, widening the gap too much, so that is another reason for the more expensive plugs. For those vehicles, I recommend you use the manufacturer's stated make and model of spark plug.

Those of you that no longer have or use leaded fuels, don't have a oil burning engine, and use full synthetic oils or quality part-synthetic, may find that your spark plugs could last 50K miles in your motorcycle. The plugs will usually work fine even with wear up to 0.040" ...often even slightly larger gap ...on a Classic K bike. They can also work fine on Airheads with widening gaps from many miles of use. Do not bend the ground electrode after any use. Because spark plugs are inexpensive relative to fuel costs, I recommend 30,000 mile spark plug replacement for Airhead and Classic K bikes, but only if using unleaded fuel.

Most spark plugs come pre-gapped, usually at or close to the gap you want, but not always. Those with single ground electrodes can be gap-adjusted if the spark plug has never been installed & the engine never run (especially under power). Be very careful not to damage the center insulator.

Some of the newer spark plugs with two grounding electrodes come pre-gapped, but the gap is typically wider than your vehicle manual says to use, and the gap would be problematical to change. In almost all such instances leave the gap alone if the gap is reasonable. An example is the plug that BMW started specifying for the K1200 models: Bosch XLR7DC. Those also seem to work OK in the older Classic K bikes with the stock 5K caps, where the original plug did not have a resistor; or, if it did have one. For longevity of the Hall sensors, I suggest you do have at least 5000 ohms in the combination of plug and cap, so be careful if you install aftermarket ignition wire and/or caps. The heat range of these plugs, 7, seems to work well even when the engine originally had heat range 5.

Before the change to unleaded fuel in the eighties, spark plugs had to be replaced at ~15,000 miles due to leaded fuel fouling. Mechanics would often sand-blast the plugs in a special blasting machine, and get more life. Not a great idea for modern engines. Leaded fuels are now long gone in the USA (except for some aviation fuels); and, the present additives, which do deposit on the spark plugs, are vastly less inclined to electrically foul the spark plugs. Engines are running leaner, which means more heat, and the spark plugs are being specified to run slightly hotter to keep deposits low, all these things keep the spark plug cleaner ...but eat spark plug metal a tad faster in some situations, and in others there is less wear; and the ignition system output has a large effect on this, with wear being more of a problem with early high current low voltage situations. That is one of the two reasons for a resistor plug & resistor cap on some models. Because modern engines are fuel-injected and burn as lean as possible and very close to optimum at nearly all times; they need powerful high energy high voltage ignitions. Most cars now have quite high performance ignition systems ...many have separate coils for each cylinder and/or fast rise times on the spark, and lots of Joule's (a measure of total energy in the spark). These systems can kill you.

NERDY: High powered ignitions can certainly eat electrodes, particularly if the resistance in the circuit is relatively low. There are some cars that have a polarity reversing method in their ignition systems ...every other spark is reversed in polarity ...this helps a small amount with erosion, but not so good with ignition performance ...unless the energy is increased ...which is often done. The net result is an improvement in lowering over-all electrode wear, or wear effects. There is also an effect on the sharpness of the electrodes, since sharper-edged electrodes will enhance the ability of the spark to form between the electrodes. There can be problems with some cars that use one coil per two cylinders, ...they need increased electrical energy. There are even plasma detecting ignitions ...won't get into that here, but I put some literature on that subject in my website. See item 18 here: https://bmwmotorcycletech.info/nerdy-stuff.htm

One method of reducing the rate of constantly but slowly increasing spark gap, due to spark/plasma erosion, is to use precious metals at the very tip of the center electrode, which do not erode so quickly; that is, the precious metal lasts considerably longer, so gaps are more constant. The precious metal plugs typically have a smaller central electrode tip of such metal, leading to higher temperature of the center electrode being possible with somewhat easier spark initiation. Don't bother, for your Airhead.

Higher resistances, such as the use of 5K or higher caps, and more turns of thinner wire in the coils are also helpful in reducing current (not voltage), which reduces metal erosion. Higher resistances have some nerdy effects. The total spark energy will decrease as the current is less, unless the voltage is also increased. The coil energy takes longer to initiate the ionization plasma and discharge fully due to the resistance, the higher it is, the slower the coil discharges, but it needs to discharge fast enough to break-through deposits yet deliver nearly all its energy, if possible, and these things work opposite engine RPM. Konfuzzzed because the speed of electricity is thought to be, by mean, constantly at the speed of light (NOPE!)? No, no going to get into this further.

I see no reason to pay premium prices for Airhead or BMW Classic K bike's spark plugs ...at least not for Iridium or Platinum tips. BUT ...if you are going to try for 50,000 miles on your plugs, you might be interested in trying them. Some of the fine wire spark plugs have another feature that is hard to describe. NGK has been at the forefront on this recently, and I described it earlier. The insulator at the tip has a taper and a L shelf. This can improve the performance. It is hard to do this with a large size central tip, so these are fine-wire precious metal spark plugs. They seem to work well in K bikes.

There are reasons to use certain types of spark plugs. In a Service Information Bulletin for the K1200, BMW went from the recommended Bosch XR5DC (Earliest prior K models had X5D, then X5DC, and then XR5D) to a dual ground electrode type XR7LDC. The XR7LDC has been adopted by many BMW dealerships for prior K models. These spark plugs have seemingly equivalent heat ranges in practice (in the K bike), ....so never mind the 5 versus 7 here. I do think the 7 is slightly hotter, by maybe half a step or tad more, in actual practice. This thin center & dual grounding electrode plug lasts longer, offers slightly better ignition under some types of conditions ...so goes the theory. Many will substitute NGK or other plugs, some are listed in the K bike section well below, and these have been substituted quite successfully. That they might be wasting a teeny bit of fuel is typically not noticeable to the riders. I am not sure they are wasting fuel, as it is difficult to measure except by an exhaust gas analyzer and an oscilloscope. The in-expensive 4163 spark plug is an example of this substituting. The XR7LDC comes pre-set for gap. It is wider than you are used to. Do not change the gap! This spark plug does not fit Airheads!

There is a lot of snake oil hype regarding spark plugs. Do not carry over my dual grounding electrode remarks to include all other engines. It is a known fact that the type of combustion chamber coupled with the intake mixture direction, and location of the spark plug and valves, on the Airheads, is such that a dual electrode spark plug is worse than the stock single electrode. This has to do with the pathway of the swirling mixture to and through/over the spark plug gap area. The so-called split tail or dual grounding electrode plugs that are hyped, SplitFire, and others, are not of any help. Worse ...for Airheads ...are the multiple grounding electrode shrouded centers ...almost always considerably worse than stock. I have removed multiple shrouded plugs (even Bosch +4 Platinum's) from Airheads because they work lousily ...& I can quote other examples.

Indexing:

A technique called indexing is often used in racing (and a few stock cars too, like the Honda Insight), for various purposes, including reducing metal-to-metal interference in very high compression ratio engines; and, more often, to point the spark plug gap at the intake valve. Supposedly this will help with initiating combustion with rich mixtures, etc. Yes, it helps. No, it does not help on stock or near stock Classic K bikes and similarly stock or near stock Airheads.

The bottom line, for Airhead owners, with stock or near stock engines (moderately increased compression ratio or dual plugs is considered near stock by me), is to use single ground electrode, extended nose spark plugs, & use of the cheaper larger center electrode plugs works fine. In other words, the stock spark plugs are fine! Don't buy the hype!

****As noted earlier, on Airhead dual-plugged heads, it is somewhat common to use a lower cylinder spark plug that is one heat range step hotter, as for various reasons the lower spark plug may otherwise tend to carbon-up faster. I've even seen 2 steps hotter used.

Very old Bosch numbers, used on some quite old BMW bikes:

W240T1: 1/2" reach, 14 mm threads, same as later W4AC. This spark plug was used on the BMW singles & a few pre-Airhead twins.

W3CC; W4CC; W5CC: 3/4" reach, 14 mm threads version of the above plug, with various heat ranges. Used on some twins.

W240R2: 3/4" reach, same as later W4C2.

W260T1: 1/2" reach, same as W3A1.

W260T2: 3/4" reach, same as later W4C1.

There is confusion over how these plugs were numbered & identified. The above is the best information I have at the moment ...but, see the chart below.

Bosch no longer has these very old type numbers even in their big thick catalogs.

Bosch has recently transitioned even their recent plugs to 4 digit numbers, see the chart below.

****In the plugs like the W230T30, ETC., as the "230" part of the spark plug number went higher in numerical order, the plug got colder, which is the opposite of the newer Bosch W numbers in the chart below.

Equivalents, Bosch & NGK:

Just a bit further down is my own simplified chart....

****Sometimes spark plugs from one manufacturer are somewhat in-between a heat range of another manufacturer, or have a slightly wider heat range capability; thus you see the Bosch 6 & 7 series being covered by the NGK 6 series. Another way of saying this is that spark plug heat ranges sometimes are not 'exact' when trying to cross one manufacturer's number with another. Complicating this is that spark plugs were improved over the years, & a single part number may now cover a wider heat range. Usually these differences are not very important.

Bosch WR plugs (not recommended for Airheads) may have the wrong gaps for Airheads! Check the gaps! Bosch plugs beginning with WR are resistor plugs! They are not directly interchangeable with the spark plugs not having the "R" ...no matter what Bosch or a Bosch salesman says!

Bosch plugs with a + sign at the ending might really be resistor plugs!! ...even if the part number does not have an R in it!

Do not use resistor plugs for Airheads. If the part number on the spark plug body has an R in it, it is a resistor plug. It is possible to be a resistor spark plug if there is a + symbol in the part number, as just noted. Some plug makers, including Bosch in its new numbering system (which I dislike, they offer no information by number as to heat range nor size) ...may not use R, or +, simply using an all numbers no letters part number! If you insist on using resistor plugs because you are too lazy to wait for an order for the non-resistor types, & you also use the stock resistor caps, your ignition may be a bit weak, but I don't see any problems beyond, maybe, hard starting &/or occasional misfiring & wasting fuel ...all depending considerably on engine & electrical's condition. You may not even notice any misfiring ...but your fuel mileage will or might suffer a little. There is a chance of more combustion chamber deposits too .

****In the plugs like the W230T30, ETC., as the '230' part of the spark plug number went higher in numerical order, the plug got colder, which is the opposite of the Bosch, newer, W numbers in the chart below.

| BOSCH, early |

BOSCH, |

BC/DC Bosch |

Latest BOSCH number series |

NGK, older |

NGK with removable nut | NGK withOUT removable nut |

Comments |

| W230T30 W225T30 |

W5D | W5DC | 7591 | BP7ES | 1034 | 3995 | W5 covers W225T30 & the colder W230T30; BMW 12-12-1-338-146. Be sure the plug is not WR5DC |

| W5B | W5BC | 7531 | BP7HS | 5111 | |||

| W200T30 | W6D | W6DC | 7594 | BP6ES |

7333 |

4007 | Champion N-9YC is OK if you can't find NGK or BMW 12-12-1-338-145. Be sure the plug is not WR6DC |

| W6B | W6BC | 7593 | BP6HS | 7331 | |||

| W175T30 | W7D | W7DC | 7500 | BP6ES | 7333 | 4007 | BMW sold W7DC as 12-12-1-267-485. May be found as 12-12-9-062-594. Be sure the plug is NOT WR7DC. Beru 14/7DU was BMW 12-12-1-265-595. BMW also sold Champion equivalent as 12-12-1-338-147. |

| W7B | W7BC | 7597 | BP6HS | 7331 | |||

| W8D | W8DC | 7505 | BP5ES | 7832 | 2140 | ||

| W8B | W8BC | 7503 | BP5HS | 4111 | |||

|

Higher numbers are colder. That is, W230 is colder than a W175 |

Higher numbers are hotter |

Plugs above ending in C cover a slightly wider heat range than the non-C & early Bosch to the left. Higher numbers are hotter |

Caution! Be sure the actual plug, for your Airhead, no matter what the carton has printed on it, is a non-resistor. See notes in this chart, & article |

Higher numbers are colder |

BMW dealerships & Independents may carry the non-resistor Bosch Spark Plugs. Be sure that, for Airheads, you do not get the WR spark plugs, which have resistors. | ||

| 'BC' : 1/2" reach | |||||||

| 'DC' : 3/4" reach |

Bosch has sometimes put resistor plugs in the small cardboard boxes that are marked for the non-resistor plugs. Also reported to me was that the number on the box for non-resistor used to start as 0-241-; and Bosch may be putting resistor plugs into those boxes, with the boxes showing 0-242-. My answer to this is to not trust what the box says ...open it and see what is printed on the plug base metal. I'm anal enough to bring an ohmmeter, just to be sure!

Here is an enlarged picture showing what one Bosch box end looks like. Do not trust anything on that box end ...look at the markings on the plug metal itself. Use your ohmmeter too.

Spark plug gap checking & adjusting: