The advertisements above are Google-sponsored. These

support the testing I do. Thank you for clicking on them at

every visit, and for your donations! The Donating article

extensively explains this website's history, philosophy, and

operations.

IGNITION:

|

Timing lights: history, types, designs, uses, internal & external power sources, etc. |

Points (both old camshaft nose type & canister types). Also covered: the pesky rubber seal that goes into the points cavity groove. |

|

Ignition modules; original, changes, updates |

New coil style changes |

|

Information on ignition timing versus piston movement has been moved to item #18 at: https://bmwmotorcycletech.info/formulas.htm |

Dyna & other points boosters |

|

Spark plug suppressor caps; also see: |

Coils: specifications, failure modes, testing |

|

Ignition canisters, repairing, etc. |

Dyna, Boyer & other ignitions |

|

Testing & troubleshooting |

High idling rpm |

|

Hall device sensors |

Rubber seal strip at points cavity, pre-1979 models |

© Copyright 2022, R. Fleischer

https://bmwmotorcycletech.info/Ignition.htm

article #30

There are several major ignition system articles on this website. You are reading article #30. You will not get a complete understanding without reading two others: #28 & #29. #31 & #32 may also be of interest. These various articles will just about completely explain everything about the various ignition's, dual-plugging, single-plugging, sparkplugs, etc. I can also recommend article #52 which covers pinging-detonation.

>>>>ESPECIALLY READ ARTICLE 29...WHICH COVERS A NUMBER OF THINGS, INCLUDING DWELL, IN GREAT DEPTH.>>>>

WHILE I DO LIST 'SOURCES' FOR INFORMATION, PARTS, AND REPAIRS THROUGHOUT THIS ENTIRE ARTICLE, THEY SHOULD NOT BE TAKEN TO MEAN THAT THEY HAVE MY UNCONDITIONAL APPROVAL.

You may wish to see Haynes or Clymers manuals. Be cautious for errors in those manuals. They are only "fair" on ignition items & testing, & certainly NOT good for repairs to the innards.

RECOMMENDED: The CHITECH BMW Electric School Manual, likely still available at $30. The description on the Chitech website is not descriptive-enough for all that is in this manual. Mostly written by super-guru, OAK Okleshen! https://www.crbmw.com/chitech-in-the-beginning/.

For a critique of that manual (and some corrections to mark in pencil in yours): https://bmwmotorcycletech.info/chitechelmnl.htm

In-depth information on spark plugs and their caps: https://bmwmotorcycletech.info/sparkplugs.htm

ALL ABOUT TIMING LIGHTS:

Many decades ago, timing lights consisted of a glass bulb containing two separated thin plates or short curled wires, or, whatever, and the glass bulb was usually filled with neon gas. Coming out of that electrically insulated bulb assembly was two high voltage insulated wires, of which one was attached to the spark plug & the other wire was attached to engine ground (case metal). This type worked fine, needed no power from a battery; but, was not very bright. It was OK for a darkened garage or engine area. There have been folks who use this method to light-up a small fluorescent lamp. These methods are all obsolete, although they do work. A lot of old-time mechanics more than occasionally got electric shocks using these methods. Getting an electrical shock from more modern ignition systems is quite dangerous, another reason for use of modern timing lights. I'll get into much more depth on various timing lights just below.

The next timing light development...and this is still from long ago... had a car radio 'vibrator' (vibrating electrical contacts) and a small transformer. The vehicle battery was used to power the vibrator, which produced a truly funky alternating current as needed for input to the transformer. The transformer output was high voltage, which was rectified to D.C. and then applied to contacts inside a smallish glass 'flash tube' that contained a pressurized gas. Sealed into each end of this flash tube was a stub wire. The high voltage circuit included a fairly powerful capacitor that could supply sudden very short time period amounts (tiny fractions of a second) of high current and voltage repetitively, to supply the flash tube power. Triggering of the flash tube was obtained in various ways, typically a few turns of thin wire was wrapped around the glass outside to which high voltage from the spark plug connection was applied to create a strong electric field which enabled the discharge of a fair amount of electric current, but of very short time length, the result of which was a bright burst of white light. Each spark plug firing caused the power supply, with its capacitor, to discharge into the lamp. Note that this type of timing light, as is today's type, was in the shape of a large hand-gun, and had a trigger button that turned the power on and off. This type of strobe light was usable in moderate sunlight due to its much higher brightness, but it still used high voltage from the spark plug connection, although some were sold that used a wire wrapped around the spark plug cable. That got utilized in a better way, in the next generation, information of which follows.

The next improvement had internal transistorized oscillators instead of the occasionally troublesome vibrator which slowly aged to poor performance. The transistorized ones were more reliable, and most had very bright outputs, some even had lense focusability. Some were still shock hazard instruments.

The next improvement was pretty much the standard type used today. These had NO dangerous direct connection to the spark plug. Instead, an adjustable spring-loaded clamp sensor probe unit simply fit over the spark plug insulated wire, and the electric field was sensed by the probe unit, amplified, and triggered the transistorized flash tube circuitry pretty much similar to the previous version of strobe lights. No high voltage connection to the spark plug wiring was required, just the spring-loaded opening 'clamp probe', that contained a coil of wire or other sensor means, to trigger the transistor amplifier, which, in turn, triggered the lamp discharge. The result was a safe and very convenient tool for shop and home, with just about no chance of an electrical shock, unless the spark plug cable wire was very deteriorated. The efficiency of some of these was good enough to allow an INternal battery source. The glass flash tube, nearly the same as previously, produced a short intensely bright white light for each spark plug spark event. The design and circuitry can be made so that the flashing is both reliable & very bright, even at high rpm. This type is still the most common.

Variations include popular types that have a rotary dial, in which degrees of advance or retard for the strobe light output can be dialed-in for special purposes. The adjustment causes the light output to be retarded or advanced, relative to the spark electrical field from the spark plug wire clamp probe sensor, and the amount of such retard or advance could be set by a dial knob. This type can be confusing, and I do not recommend its use, unless you already have one & know how to use it; or, will learn to do so if you purchase one. This type is absolutely not needed for Airheads use, and that includes stock single plug ignition as well as dual plugging; and, AFAIK, not needed for any aftermarket ignition. If you are purchasing a timing light, and are the more nerdy type, you might want the type with a dial for timing degrees setting. While all these common types of strobe lights are pretty much the same (with or without the set-timing dial control), there are some that are more rugged, feel better in your hand & some run off internal batteries instead of the vehicle battery, and many have glass lenses at the nose to concentrate the light or focus the light better. Some have a substantially brighter light output than others.

Variations on the timing dial type are versions that will enable dwell time to be measured or displayed. Dwell time is, put simply, the number of rotational degrees (of 360) during which the ignition coil is being magnetically charged from electrical input, compared to the number of degrees of time of not-being-charged. Contrary to some beliefs and statements, dwell time measurements are not very important to BMW Airhead ignition, any advice to the contrary is not based on facts. Dwell time is more important on engines with one or two coils AND many cylinders, because the longer the dwell time, the better the coil charge, particularly if RPM rises quite high. There is no way a BMW Airhead engine will have a problem with the normally used coils, even at 7500 RPM. The control over dwell period is the points opening; or, if no points, the mechanism that produces the ignition signal ...and, in a few instances ...the electronics modules that may have dwell circuitry. Dwell period time problems with points or points rubbing block wear is possible, and use of too small points gap settings will lead to problems.

Timing light power sources (internal battery or external battery or the vehicle battery):

Timing lights are available that do not need external power sources, that means that the timing light needs no connection to the vehicle battery, but uses an internal battery, usually rechargeable. These can have a possible advantage besides not needing the vehicle battery or an external battery. In rather rare situations, using the vehicle battery to power the timing light (and the ignition of a rotating engine) can cause irregular timing indications. Usually this is in a system with a poor (higher internal resistance) battery, or other fault, so low value engine ignition pulses are seen at the battery terminals which would otherwise be powering the timing light. Some mechanics use a standard timing light that uses external power, that means they use another battery, not the vehicle battery, for power. I have had to do this myself on quite rare occasions. In every instance, the problem occurred (again, it is rare), with electronic ignitions.

In most instances, with most timing light models, one uses, for convenience, the vehicle battery for timing light power. An extremely rare instance is when the timing light itself produces electrical noises, upsetting the timing reading. Less rare but I still consider it quite rare, is when some other problem exists in the vehicle causing strange timing light indications at the flywheel (called the clutch carrier on 1981 and later BMW Airhead models). This can be from such as a bad battery; poor connections; or, in some instances just slightly higher connection resistance at some place(s) in the vehicle ...or, there is electrical noise from a poor diode in an alternator diode board, etc. If some form of electrical noise, including delayed ignition impulse noises, feed back to the timing light via its battery connection, the timing light output can be irregular. These possible events are reasons that some mechanics power their timing lights from an external battery (few use internal battery types, although they may become more popular in the future). So ...there is a possible problem with reading the timing marks clearly and accurately, if the timing light is vehicle powered. This can happen, but almost always does not. The possibility is why BMW recommends using an external power source for the timing light. Such an external timing light power source could be almost any 12 volt battery that can power the timing light.

It is relatively common to see somewhat irregular and unstable timing light indications at the flywheel (clutch carrier) timing marks; ....especially at both a low to moderate idle RPM; but also perhaps at high RPM. Since unstable timing marks are usually due to timing chain and guides and sprockets wear, or irregularities at ignition points, if there is any question of accurate timing, I suggest you do try an external battery instead of powering your timing light from the vehicle under test. We professional wrenches often use the stability of indications to suggest problems with parts wear in the timing chest.

More about false timing light 'information':

Any sort of electrical noise at the battery terminals where you have connected the timing light ... can, but does not have to, ...cause false triggering. Some timing lights are much more susceptible to triggering on electrical noise including faulty ignition pulses at the spark plug ignition wire. False triggering can make it more difficult to determine which of multiple images on the flywheel (or clutch carrier) is the correct one. Multiple images on the flywheel are quite common and usually come from irregularities in the bike's own ignition triggering, almost always from jerking-about of the timing chain, and not problems with the timing light. Irregularities in a points drive can be mechanically caused from run-out at the end of the camshaft (especially Airheads up through 1978). The points-in-canister models of 1979-1980 are more stable than the older points-at-end-of-cam models, but the 1979-1980 is less stable than the electronic ignition of 1981 & later. Irregularities with the 1981 and later electronic ignition timing might come from the mechanical drive to the canister (unusual), but it is usually wear at the chain, guide/tensioner and chain sprockets. It is very easy to see the instabilities with a timing light and use of throttle to vary the RPM.

>>>Try an external battery. If any substantial difference, then best to use an external battery with that timing light. NOTE that some timing light ignition 'pickups' have a marking on them to show the direction they should be fitted over the ignition wire. That marking, usually an arrow, almost universally means the arrow points towards the spark plug, NOT THE COIL. Try both directions on your vehicle, see if any difference. I have seen differences due to internal coil winding polarity at the coil terminals, and for other esoteric reasons. Check at both low RPM (such as at idle) and at high rpm, both directions for the probe.

While the best thing is to power a timing light from an external battery, quite frankly I seldom do that myself ...unless I am specifically looking into certain problem situations. Problems are rare with timing lights themselves. Timing light strobes do fail or wear out, usually it is the vibrator and/or tubes or capacitors or a transistor, depending on era.

I suspect that most all of you will use a timing light that triggers via a clamping probe over the insulated ignition wire, and that has no advance/retard dial. It works fine on our Airheads, no matter if single plug, dual-plugged, one coil or two coils, aftermarket or stock ignition.

On an after-market split ignition, such as the separately-cylinders-adjustable Dyna unit used on the early points type motorcycles, you must set the timing for both cylinders individually. Theoretically this produces a more accurate, less jittery ignition timing. In practice, that MAY be true, but usually is fairly modest in effect. It can also mask some of the aging of the chain, sprockets, & guides. However, another way of looking at this is that since each cylinder is separately 'timed', the ignition is more accurate.

Points amplifiers, sometimes called points boosters:

These used to be made by quite a few manufacturers; but, since the now near universal use of electronic ignition, there are few makers (and I know of no commercially available ones with some of the fancy timing circuitry that was available on a very few, long ago). Today, points boosters/amplifiers are made by only a small number of manufacturer's. They will ...or CAN ....GREATLY increase points life. Accel was a popular brand, and Accel still sells high quality ignition coils. Dyna still sells a booster unit that has been popular for a very long time. These are two of the popular makers in the USA, but kits are available from others, and may have some advantages, with ability to handle lower primary ohms coils and possibly produce better sparks and the reliability may be better, particularly, perhaps, in hot engine areas. Still, since all these units contain transistor electronics, I HIGHLY recommend they not be mounted in hot areas, particularly not mounted to hot engine surfaces. See my references article; or, at least the rest of this section:

Points boosters or points amplifiers do NOT boost nor amplify the ignition spark. What they do is to allow the reduction of the points electrical voltage and current, so that the points have, essentially, no electric spark erosion; or, call it no or hardly any, electrical spark wear. A quite small current passes through the points, although most are designed to have enough so that the points continue to make good electrical contact. It is important, with use of these boosters/amplifiers, that the points cavity, or points canister innards area at the points, be clean and totally free of oil (free of even the tiniest amounts as vapor). These boosters/amplifiers have no effect on the life of the points spring, nor, especially, the life of the points rubbing block. If the points cam (and felt on models having a felt) are kept very lightly lubricated, then the rubbing block will last very much longer, and you will not get squeaks and not have to adjust the points gap and timing very often. That is true for use with a points booster/amplifier; or, points without a booster/amplifier.

KITS are available to put together your own points booster/amplifier:

https://store.qkits.com/

http://www.apogeekits.com.

Also, Arcade electronics; and maybe others.

Velleman is probably the actual maker of all those above kits sold by others, using model number 2543. https://www.vellemanusa.com/. Best, perhaps, is to use: https://www.vellemanstore.com/.

If any of the above links are NLA, then do an internet search.

A problem could occur if you have coils that draw more amperes than any of the points booster amplifiers are rated for, typically rated for 4 amperes for the Dyna Booster and most others. Many have used a booster in an overloaded condition, if they are kept reasonably cool. AFAIK the Velleman is also rated at 4 amperes, but the Velleman is available as a kit, with a large heat sink (as opposed to the SEALED Dyna unit)....and, with the heat sink that comes with the Velleman, I think the unit will handle even more amperes if placed in a relatively cool place on the motorcycle; ...someplace under the fuel tank? I think you could also install a more powerful transistor, on a substantial heat sink.

Even with a points booster/amplifier, you MUST keep the points cam faintly lubricated, or it will wear fast, & may even squeak. The points MUST be clean and dry! I suggest you continue to check the points at 5,000 mile intervals, and if you have a booster/amplifer, run a piece of very clean non-glossy paper through the points to clean them of any very faint oil contamination that gets past the points cavity seal.

NEVER open the points manually very much; opening them quite wide might weaken the spring, although this is overblown in some published literature or on-List.

The NON-canister Airheads have points located on the forward (nose) end of the camshaft in a small engine cavity. The lower points screw head is very close to the points spring. If a wrong screw or washer is use, the screw can contact the spring and the points are effectively shorted, and you get no ignition. This is seen now and then right after someone replaces the points and can't understand why the engine will not start.

Every now and then folks replace the outer aluminum cover and don't pay attention to the points wire. It gets crushed. The ignition might get shorted out immediately...or, it could take some heat/cook cycles before the bike fails to start or run OK. The NON-canister models points connection wire goes from the points cavity through a rubber grommet which often gets displaced when working in the area. DO NOT replace the cover until the wire & grommet are in proper position, or you could cut the wire when replacing the cover. You can use a strong adhesive on the grommet to help prevent displacement ...I suggest 3M or Permatex "super-weatherstrip-adhesive". The BMW price for that grommet will help empty your wallet.

Their is a rubber seal-strip (or rubber O-ring, whatever you want to call it), located in the pre-1979 timing chests, in a groove surrounding the points cavity, having had multiple part numbers in the parts fiche. The situation with them can be confusing. The material came in both short strips, and much longer pieces. You should find out which rubber will properly fit. Install a precisely cut length after cleaning the rubber with acetone or MEK. Clean the cavity groove quite well. Put small droplets of cyano-acrylic glue (Crazy Glue, etc.) in the cavity groove, before installing the rubber. You can also use tiny bits of Super Weatherstrip Adhesive. Push the rubber (do clean it with solvent first) a few times into position as needed. Cut with an Xacto knife to fit; press in again, and let sit overnight. Make the cut as precisely as possible, leaving the most minimal end gap you can...so the pressure of installing the outer cover will cause the seal to be 100%. Next day; clean lightly with acetone on a rag a few times, to get any excess glue removed. DO NOT rub with a bar of soap as the next step after the acetone cleaning. DO NOT use soap at all! I smear a VERY SMALL amount of silicone dielectric grease on the surface, using my fingertip, before replacing the outer cover. For the rubber material, 11-14-1-265-394, is supposedly 3.2 mm thick, used until 1974, approximately. Some fiche imply to 1975. Thereafter, and some fiche say for 1976 to 1978, you are to use 11-14-1-262-644, which is supposedly, in some fiche, 4.2 mm. Awhile back, if you were to order either, you would probably will get the -394 size. Maybe. You MAY be able to use a Classic K bike oil filter cover O-ring, which is 11-13-1-460-425, even a used one! Do clean off the oil with acetone. That O-ring is 88 mm x 3 mm in size, and is used on the Classic K bikes which are K1, K75, K100, K1100 ...at the oil filter outer cover. The O-ring is also used at various places in such as a R1200GS, and K1200. You need to check the particular groove in your Airhead, see what fits. When ready to install the outer cover, be careful; watch the installation ...there is a rubber grommet which has a groove that mates with the outer cover ....and you do NOT want to pinch the wire from the points....and, as has been mentioned, also consider using superweatherstrip adhesive on the grommet. Some use home in-wall solid copper wire for the rubber channel, usually used is the type with plastic insulation. If carefully selected for wire gauge or metric size, you can provide a decent sealing. I prefer not to do that, but to use an all-rubber O-ring, as noted.

Cleaning points:

Rotate the engine until the points are closed (they are then pressured by the points spring blade). Next, open them by hand only a very small amount, just enough to slide a piece of paper between the points. Absorbent paper of some sort, but not a linty paper towel. I have used a non-glazed business card or a bit of common printer paper. First put a couple drops of a fast drying solvent on the small piece of paper. Acetone is fine (not wife's oily based acetone). Acetone or other strong fast evaporating solvent on the piece of paper will remove any oil film layer on the points. You do not want to file the points because that will remove some of the special metal layer plated onto them. Points are expensive, so you may decide to file them anyway when they get worn/erroded a fair amount. If you have to file them because there is a pronounced tit and valley on the points, do it only lightly, and use a fine grit points file or thin flat jewelers file. Keep the tool square to the points and do not finger pressure the points much. I have used diamond or carbide grit impregnated METAL fingernail 'boards', and they work fine. DO NOT overdo the filing and don't file at all unless you have to. The points can have a mild tit and valley and still work fine.

Be sure to lightly lubricate the cam felt (no felts in canister points models) ....and lightly lubricate the cam only SLIGHTLY, with any good soft but high temperature rated grease. Check the points every 5,000 miles for gap, clean and refresh the faint amount of cam grease, and check timing. Do not over-lubricate! Remove old grease first. You do not want grease or oil to get into the points gap!

Be sure the points cavity area is clean and dry; pay attention to the rubber grommet and wire as you put the front cover back on the bike. I will assume the seal for the cavity is good & intact. It's a good idea to VERY LIGHTLY coat the surface of that seal with such as silicon grease (dielectric grease at your auto supplies store).

1979-1980 models have the points located in a canister (which, after 1980, do not have the points, but contain the Hall transistor device). There is no wiping felt for the points rubbing block. Do the best you can with teensy rag bits, and soft high temperature lubricant sparingly on the cam.

Ignition points/ATU/etc:

The ATU (Automatic Timing Unit) is discussed, in depth, at

https://bmwmotorcycletech.info/ignitionsingleplug.htm

SEE ALSO, item 5., well below...

ADDITIONAL information, especially about a high rpm idle problem, is treated in this article, a number of paragraphs below.

CONDENSER: An old-time name for an electrical part properly called a capacitor. 0.2 microfarad, typically for points models.

DWELL: This is covered in depth in: https://bmwmotorcycletech.info/ignitionsingleplug.htm

CANISTER POINTS:

Ignition points as used in the Airhead canisters (1979 and 1980 Airheads models):

Unconfirmed data: Bosch GB534 ...as on Mitsubishi Colt (69-80 6 cyl), some VW (Bus to 1972 for instance). The 01-011 VW points may fit the canister (number may be shown as 01011). Those points have a more standard spring tension, use a fiber rubbing block. If you were using very high rpm all the time, racing, or?, you might want 01030 which has a stiffer spring & plastic rubbing block. Volvo, some Toyota, Ford Cortina TD and TF, 6 cyl Falcom XY and XD, ....etc. Old VW points springs may be too weak, and cause floating problems. NOTE: Porsche & some others, used Bosch GB752, which had a slightly higher spring tension, so less tendency to have floating problems at very high RPM, ~red-line area. Do not willy-nilly install those points, because BMW has a stronger spring points unit for the canister ignitions, it solves a problem seen, if rarely, with misfiring at & above 6500 RPM. NOTE my previous mention of problem if the points are opened much too wide. The part number, which was finally adopted for all the canister points models is: 12-11-1-243-969. This item can be differentiated from the softer spring model by the color of the wire insulation, which should not be black, but black with white rings, or white with black rings.

In Europe, BMW made other changes at the same time to this canister, changing the vent hose to a white colored one (12-11-1-243-920), and the cover went to 2 hole mounting.

The 1979 & 1980 Airheads had canisters with points & did not have a felt pad to help keep the points cam lubricated. If the lubrication on these or earlier points cams dries out, the rubbing block & the cam can make loud chirping or squeaking noises. This indicates that the rubbing block is wearing fast; soon the points will have no opening, & the bike will stumble and eventually quit running or be difficult to start. Remove the outer lid (1 or 2 screws) & lubricate the cam sides very sparingly ....with a high temperature grease ...or, real ATU grease from Bosch. Put one drop of a decent oil on the outrigger bearing if the canister model. Note that the points can not be adjusted properly without the outrigger bearing in place. Do not open the points manually beyond what is needed ....doing so may cause them to loose spring tension and you can then have ignition abnormalities at high rpm.

I DO lubricate the canister cam in the 1979-1980 canisters that have points, & I do it very lightly. There is no felt in most if not all point sets for these canisters. Lubricating the cam lightly (you may have to clean it first) certainly extends points life, & is easy to do. More serious work on the canisters requires a difficult disassembly.

NON-canister Points, that means Ignition Points for 1970-1978 Airheads:

BMW has shipped wrongly made Points, made in China. They did that under part number 12-11-1-243-555. The rubbing block is too long & you cannot get proper timing, etc. Can you modify them? ...I don't know. I have suggested the Noris points from such as Beemershop, etc. Noris, of Germany, was an original manufacturer of BMW points. I am fine with you using Noris points. For some time now BMW has been shipping 12-11-1-243-556, which fit & work OK. Check BMW prices and prices from Bob's BMW, and Euromotoelectric, Tom Cutter, Bud Provin, etc. The requirements for lubricating the points cam also exists for these older model bikes, plus the shaft (cam end) also needs lubrication. Do not open the points manually beyond what is needed. These older motorcycles have a felt as part of the points assembly & it should be kept slightly lubricated. Before the 1979 introduction of the canister, Airhead motorcycles all had points ignitions with felts; the felt and cam required lubrication (both on the engine cam's shaft inside the ATU, and the ignition cam outer surface). Since the automatic advance unit was at the cam tip (not buried as in the canisters), the automatic advance unit cleaning and lubrication could be done rather easily; with two types of Bosch greases used, one for the rubbing block, one for the area between automatic advance and cam ....and the shaft.

DO NOT overtighten the nut holding the ATU to the camshaft tip. There should be a waverly locking washer used with the nut.

Rotating the points plate CLOCKWISE in pre-1979 models will retard the spark.

Don't use the coils with the lightning bolt symbol with points without a high power rated booster.

High Idle RPM (usually after warmup, perhaps as high as ~2000RPM; ALSO, excessive advance range:

These are primarily problems with the ATU mechanism in the CANISTER models. It is possible for the older style ATU to have such problems, but cleaning and lubrication and inspecting for slacked springs on them is easy, and does not need a lot of explanation or caution ...except to NOT overtighten the nut at the tip of the cam!

High idling rpm, perhaps slowly worsening (?), is caused by several possible problems. Sometimes there is more than one of these problems at the same time. Excessive advance range will also be dealt with here. Sometimes the problem is in carburetion, also dealt with here.

1. An internally "sticky" automatic timing unit in the ignition canister at the front of the engine. I discuss how to determine if this is the problem and how to fix it, at 7.

Do it yourself, cleaning and lubrication of the ATU: http://gunsmoke.com/motorcycling/r100gs/auto_advance/index.html

Overhaulers are listed considerably down, near the end of this long article, in its own section.

Another group of photos on how to clean and lubricate the ATU: https://www.flickr.com/photos/getproductions/sets/72157644751098893

2. Leaking throttle shafts; hoses/clamps ... and sometimes leaking intake stubs to carburetors. If the carburetors are sagging, easily seen as the hose from the carburetor outlet to the cylinder head is sagging, tightening usually won't fix things. BMW made a change to the hoses on the GS, and some got on other models, and the hose change is a problem. Info in my carburetor articles.

3. Wrongly adjusted carburetors (usually the idle mixture screw).

4. No slack in one or both throttle cables; or, no slack in the top cable on three cable models.

5. Weak or stretched/sacked automatic advance springs. This is not difficult to determine; a visual look-see will show one or more of these conditions:

(a) PRE-1979 models: The springs do not fully bring the advance weights back to engine stopped position. Usually there is a wee bit of play BEFORE the springs expand (if you move the weights manually).

This can also happen to the 1979 to 1995 canister models, but less likely. For them, the easiest method is to remove the tiny elliptical side plate, and look carefully inside, and use a tiny tool of some sort, to see if the weights have fully returned. If they are sacked, you have to disassemble the canister.

(b) The idle timing may vary more than normally.

(c) The timing RANGE is likely OK, but RPM at which maximum timing is reached is much lower than expected; or the range is otherwise incorrect and needs looking into.

Source for automatic advance springs:

https://www.motobins.co.uk

If the RANGE of automatic advance is EXCESSIVE, you may have bad plastic bushings on the ATU unit. Excessive advance range can be described as: you set the ignition to properly have the S mark centered at idle rpm, but find the maximum advance quits advancing at considerably higher than 3000 RPM.

6. Carburetors wrongly assembled, or other problems. This includes leaking domes; leaking throttle shafts (see item 2); parts of the enrichener gasket are pulled inwards; wrongly assembled enrichener discs or lever assemblies; & wrongly stamped L or R (by Bing factory!!) enrichener shafts. Photos of the proper and improper assembly are in my carburetor articles.

7. Perhaps THE most common problem, if the increase in rpm is quite large, such as to 2000 rpm or so, is a sticky automatic advance unit (ATU)...almost always this is in the CANISTER MODELS ...resulting in a high idle speed due to excessive timing advance, typically after a full warm-up of the entire engine. A full warm-up takes at least 10 miles. Usually you must have the engine case hot, not just the cylinders, for this excessive advance to happen.There are several TESTS and THINGS TO KNOW for PROVING that the ATU is at fault for a high idle rpm after full warmup (rare before full warmup):

(a) Make sure that there are no vacuum leaks at the intake rubber hoses. To do this, start the engine, let it idle (OK to be somewhat above idle to keep engine running, if doing it with a cold engine; should not be needed with warm/hot engine), & spray brake cleaner or other spray solvent or even butane/propane, etc., at the intake hoses, both ends of them at both L & R cylinders. NO rpm change should be noted in these tests ...nor the next ones. If there is any RPM or sound changes, tighten the band-clamps at the hoses between carburetors & cylinder heads & re-check. It is possible for a hose to deteriorate and tightening will not help, so replace the hose if that is found. If replacing a hose on a later model Airhead, particularly a GS, but this has been seen on other late models, be SURE the hose has the correct number printed on it ...see my carburetor articles; because BMW made a change I do not agree with.

(b) Next, spray at the throttle shaft linkage area where the throttle shaft exits the carburetor. If the internal throttle shaft O-ring is bad, you will have to disassemble some of the carburetor to replace it.

(c) Make sure that there IS free play in the throttle cables at idle (throttle rotated to off); and, that there is NOT a wrongly adjusted idle mixture screw.

(d) In some instances, just turning off the engine & restarting it after it was already hot & exhibiting the very high idle, provides inertia of starting forces sufficient to 'reset' a stuck ATU ...so try that. If then a normal idle, it IS likely an ATU problem. A few repeats, & if this is the situation, you can be nearly 100% sure it IS the ATU needing attention.

(e) If restarting doesn't show up the problem, then do get a friend's help. First take the bike for a 10-20 mile ride, & if the idle rpm went quite high (~2000..??) after a full warmup of the engine case, then pull the bike up to a nice big solid object, like a brick building wall. You could also just use the brakes. With the bike in first gear, still idling at the high rpm, throttle off, let out the clutch very slowly, which loads the engine, slowing it. Slow it slowly down to ~900 rpm.

Have your friend use a timing light, triggered from a spark cable by clamping the sensor pickup over the cable. It is OK to use the bike's battery for powering the timing light for this test. Have him point the light at the timing hole near the oil dipstick. If the timing is quite well-advanced & not where it should be, which is close to the S mark at this slow idle rpm, then the ATU definitely is the problem. Prove it by pulling in the clutch ...you have a very high idle rpm again, yes? Try several times. If the idle does not go high again, then you may have 'reset' the ATU, and while not mandatory, I think you should do a bit of a ride and then repeat the testing again, to be absolutely sure of the ATU being the problem.

(f) The proper and full fix is to disassemble the canister & clean & re-lubricate it. That is not all that easy for the novice. Sometimes simply removing the oval side plate & squirting in some cleaner &/or a fine oil (not ever WD40, which tends to solidify over time) will help, but may ...or may not ...hold up over time. If doing that, be sure to shake out the excess. When disassembling the canister, some of the ATU parts may need to be burnished (sort of a more complete polishing with a very fine grit sandpaper or silicon carbide paper) which does help. Typically a careful cleaning & polishing by such a very fine paper, finished by light lubrication, is going to fix the problem, permanently. Fine grit means around 1000 grit, but you may have to begin with a bit lower.

(g) You could have slacked or otherwise weakened ATU springs. Easy to test for, use eyeball & the timing light, and look at the springs, through the elliptical side hole.

Source for automatic advance springs:

https://www.motobins.co.uk/

Assuming you have fixed the high rpm problem & all is OK, there are things you should do, besides resetting the canister timing adjustment. Be sure the valves are properly set! Now re-sync the carburetors after a ride or other warmup. During the re-synchronization, pay special attention to the idle mixture screw, idle balance, & ending idle rpm (1000-1100). Many do NOT set the idle mixture screw properly. If not set properly, the idle RPM can vary considerably more than normal from cold, or just barely warmed, to a fully hot engine. Start with the idle mixture screw further out than factory or Bing or other manual such as Haynes or Clymers says initial adjustment should be. An extra one full turn is always enough. From that further out point, slowly screw inwards, until engine rpm and sound peaks & then slowly more until the rpm falls off a bit ....you will hear some engine stumbling and heaviness. Back the idle mixture screw off slightly to the exact peak of rpm and sound. Then back it off an additional 1/8th of a turn (not over 1/4th, and that is usually a bit too much). Go back & forth between the idle mixture and idle speed adjustments until carburetor adjustments are such that no further improvement can be made. The shorting method works very well here, read the article, link below. You must synch the carburetors so the effective rpm on both cylinders is the same, and the effective idle mixture is the same. You cannot do this properly without the shorting method or using an instrument (which is a bit less accurate). If you take more than a few minutes for all this, either ride the bike to cool the engine a bit; or use fans blowing on the cylinders.

This website has an article that describes how to get an appropriate squirrel cage fan for nothing. https://bmwmotorcycletech.info/tools.htm

See the following article for how to adjust carburetors: https://bmwmotorcycletech.info/synchcarbs.htm

A rare, but super-annoying problem to find, ....but a simple fix:

Do you have a BMW electronic ignition Airhead that will idle OK, but won't raise rpm properly? This problem acts somewhat similarly to a hole in one or both carburetor diaphragms.

The actual problem is in the ignition kill switch at the bars. Just cleaning that switch may (or may not) fix the problem. Bypassing the switch will show whether or not the problem is that switch. This fault has perplexed even some senior technicians trying to find the source of the problem. I first ran into this situation long ago, & finally identified it, after a lot of labor. I used an oscilloscope to find the problem. I found that an ohmmeter or voltmeter, for rather nerdy-techy reasons, might well not show any fault. It is rare, but when it happens to you, & you have the bike at your favorite repair shop, you can expect a large amount of labor ...and maybe a lot of 'guessing & shot-gunning' of parts replacements. Try what I suggest, bypass the switch connections. If it is your problem, you will be thanking me!

Problems, testing, etc., ....the stock BMW/Bosch electronic ignition canisters:

+ Sources of information/parts for Airhead ignitions, etc.

Intermittent ignition failures on 1981 and later can come from the Hall Effect element aging or partially or intermittently failing, often with temperature, but some testing should be done before making conclusions.

Remove both spark plugs. SECURELY fasten each sparkplug, so that the threaded metal bodies contact to cylinder or head fin metal. You can use a bungee cord for this. I prefer to use a screen door or sash spring, so as to give a bit of added safety. You do not want them or their caps becoming disconnected, as that will injure the ignition. Next, disconnect all battery negative terminal wires. Remove engine front metal cover. Reconnect battery. If you have an EnDuralast permanent magnet alternator, you need not disconnect the battery before removing the front engine cover.

The three pin connectors that connect the the canister to the bike wiring has one thin wire bale clip around it. That bale clip must be removed before you try to unplug the connectors from each other. Pry at one end of the bale wire clip with a tiny tool, & then carefully remove that bale wire clip, don't overly widen during removal...it needs its springy-ness and proper fit. Unplug the connectors, good workmanship is to not tug on wires, only the plugs. The 3 spade connectors in these male & female plugs are known to get very minor corrosion, sometimes invisible. Cleaning with an eraser & then a slight poof of contact cleaner-treatment, will likely fix the problem. Just disconnecting & reconnecting the connector halves may be enough wiping friction on the connections to make a good contact again. The plugs are replaceable, if hard to find. Try Tom Cutter's Rubber Chicken Racing Garage; or, Euromotoelectrics.

Be sure the kill switch on the handlebars is centered. It is a good idea to move that kill switch back and forth a few times, particularly if you seldom ever use it. With ignition switch on, see if the engine now has sparks at both secured spark plugs during cranking; ....if so, you had some corrosion on the connector spades, or, there is a temperature problem perhaps. Most of us Wrenches do that test right away.

If there was no spark at the plugs (should be at both, during kill switch rotation back and forth), then, ignition off, disconnect the two connector halves again. Use a bent metal paper clip (or whatever) & insert it into the center connection on the engine side connector. Turn on the ignition, again be sure KILL switch is centered to 'run' position. Repeatedly touch the paper clip to the engine case, which repeatedly grounds the center connection. You should see sparks at the spark plug (darkened room may help). If none, you have problems in the module or power to it, or an open coil primary. If you do get sparks, you have a bad canister Hall device. Don't lose the bale wire clip; reinstall it after you treat the connections with Caig DeOxit and push the connectors back together, before you button up the front cover.

DO NOT look for sparks without being sure the removed spark plugs are attached to the ignition cables, and the plugs hex metal is in contact with the cylinder or cylinder head. You can injure the ignition if the system is not thusly grounded during testing.

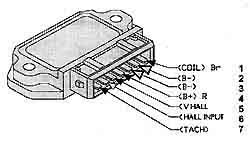

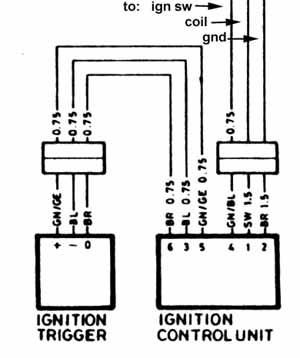

The Hall element/transistor/device, etc. What are they? How do they fail?:

The Hall device as used in the ignition of the Airheads, Oilhead, K bikes, ETC., is a special type of transistor, that has a variable voltage output depending on movement of a magnetic field next to the element. In theses motorcycles, a moving metal vane passes by or through the device, and the result is a small but accurately timed output voltage, that can be applied to a special transistor amplifying and processing circuit that is usually called the Ignition Module. That ignition module has been located in two general places. One of these places is where the earlier ATE front brake master cylinder had been mounted, forward area of the top frame tube. This installation used a mounting plate which acts as a heat sink for the electronics module, which otherwise would overheat. Later models had the module mounted on a heat sink and located on the right side of the top frame tube; there were two versions of mounting. Modules are powered by the battery and triggered by the Hall device. The output of the module drives the ignition coil(s). See the next SECTION of this article, well below.The Hall transistors have been known to become intermittent, or to fail during temperature changes. The Hall transistor problems usually occur after engine warm-up; the ignition gets intermittent, or dies; and often recovers after the engine cools some. In some instances, usually rarer, the ignition can fail for a few seconds only, cause back-firing in the exhaust, etc.

You can test the Hall device for temperature problems by going for a ride. I suggest saving time....so, before the ride, remove the front engine cover. You can certainly run the engine without that cover. Take along a large can of Cool-Spray (or similar) with you. If it normally takes perhaps an hour (or??) for the engine to be restarted, & if you cool the canister enough & fairly quickly (It can take a lot of spray cooling) ...& then the engine starts up ok, and it would not, in previous tests, you almost for sure have a Hall device problem. I have done this testing by quickly removing the outer cover and spraying into the unit a bit....takes a lot less cool-spray.

HINT: In the last of my tests of using cool-spray, I decided to modify the outer cover of a canister, so I could spray into the canister with the tiny tubing of the cool-spray can. I REMOVED the cover, and drilled a quarter inch hole in the cover, well away from the center bearing area. Two long (5 second) poofs of cool-spray, then start and ride off. Repeat whenever the engine acted up. Determine if the Hall device was the problem. When done, I plugged the hole, to avoid dirt getting inside the canister.

The Hall device is replaceable, but BMW only sells the complete canister, very pricey indeed ....but with this article you can repair them, or send them to someone who can. Tom Cutter is one of those that can repair them.

Always check the ignition module located beneath the fuel tank (unless latest riveted type on the later heat-sink, which don't, supposedly, require fresh head-sink-paste, ever) to be sure it has good heat sink paste under it. Failure to have good condition heat sink paste under the module will allow it to overheat, usually not too long after the bike is started; the ignition typically acts up or totally quits, until the module cools down. After enough of these overheating occurrences the module will likely fail completely. Generally, I recommend cleaning off the old heat sink paste and replacing the paste every year ....or three at the latest.

MODULES (a very long section, covering nearly everything about them for your Airhead motorcycle):

Stock Ignition modules:

Common ignition problems (1981 & later, except riveted modules) include failure to clean & renew the heat sink paste under the Module under the fuel tank at reasonable intervals. If the heat sink paste is old and dried out, the Module will tend to overheat & cause ignition problems after the bike has been on the road awhile; and too many overheating cycles will result in module failure.

NOTE: The later modules are riveted-in-place, and not supposed to need fresh heat sink paste (and, you'd have to drill or? the rivets..). So, questions may arise: What sort of 'permanent' heat sink paste/compound, if any, is used in the riveted versions? ETC ETC. I don't know! I've never de-riveted such a module to try to find out. You could be the first to know!

There is more than one location place for the ignition module on the Airheads (1981+) depending on the model of Airhead and its manufacturing year. The 1981-1985 R80G/S, 1983-1984 RT80ST, 1981 to 1987 R65, 1982 to 1984 R65LS, 1985 to 1987 R80 and R80RT, & the other bikes from 1988, all have the ignition module on the right side of the frame backbone tube under the fuel tank & are just behind the ignition coiI. All other models have the ignition module located directly under the fuel tank on a flat aluminum plate, attached where the old ATE brake master cylinder from the seventies was located. Modules that are fastened by screws to its attached plate can be unfastened by those screws in order to clean the bottom of the module & the plate, before applying fresh heat-sink paste, which MUST be done every year or three at the latest. Tighten evenly & moderately tight.

Listed here are reported modules that MAY work OK. The word MAY is being used here, because there may be complications, particularly if you have the later 0.5 (often called 0.7 ohm) twin tower coil. It is my belief that just about any module would be acceptable for emergency use ...but may not work 100% properly, so are only recommended for emergency use. Some people carry one of these on the motorcycle, but modules don't fail often.

Bosch 0227-100-116.

GP Sorensen 11-5064.

NAPA (Echlin) TP100 (supposedly from Globe Motorist, but will not sell small quantities; Napa prices were considerably higher, but worth a look/check).

Standard Motor LX501.

Wells Mfg RB100.

MANY cars use similar modules. They may not be same for logic/timing, but probably will at least function. Don't leave the key on for long periods of time with engine not started, as the internal timer may not function the same, if even present.

Transpo BM-300 Rocky Point cycle.com Also has #9604, Ignition Module, made in the USA. Has Part number 9608, Ignition Module, made in the USA, for the Classic K bikes. Also sells the Boyer-Bransden Ignition. A Microdigital ignition advance curve is later in this article.

VAG (VW and Audi) ignition module part nr. 191 905 351b is a drop-in replacement for the earlier Airhead modules.

Cars that you may find modules on in wrecking yards, or can get modules at auto-parts stores, besides what has already been mentioned:

VW Golf and Passat 1979-1989.

VW T2 Transporter and Jetta 1979-1992.

VW Scirocco 1979-1995.

VW Corrado 1979-1995.

Audi 100 1980-1993.

Audi 80 1979-1993.

Audi Coupe 1981-1994.

The Airhead ignition modules (under the tank modules) were initially made in two versions. On these earliest modules, a spark 'could' occur when the key was first turned on; later versions fixed that (but, the KILL switch could do it, and many of us find THAT to be rather convenient during testing). One of the two early versions was for the kickstart bikes and the other version was for the no-kickstart bikes. These early modules supposedly had a timing feature that cut off the current flow through the module and coil(s) after about 5 seconds for the kick-starter-equipped bikes & about 1 second or so for the no kickstarter equipped bikes. Later this was, per BMW, changed to about 1.5 seconds (UNclear to me, but perhaps this 1.5 was for both ...or for the kickstarter equipped bikes...not sure). The kickstart modules timings were originally longer to allow time to kickstart the bike ...which is a bit strange, since engine rotation supposedly causes the modules to be triggered. My guess is that the current cutoff was not perfect under all conditions; and I think BMW's information was not correct for all the early modules. The reasoning behind a current cutoff was to reduce heating of the coil(s), which supposedly was the, or only one of the, causes for the original twin-tower gray coils to fail by cracking. Apparently, some folks would turn on the key; continue a conversation, without starting the motor. Perhaps the real reason (?) is that some very early modules never had such a timer at all ....which I have seen some indication of. Yes, this is all confusing, and BMW's bulletins never helped the confusion, in fact, made it worse; and, while I have, in this article, gotten deeply into it all, keep in mind that I try to cover everything, and you may well be confused by what I post about here. The coil redesign for reliability (no more cracking) did not result in any change in the electrical characteristics of the coil. I've never been curious enough to chart all the coil drive characteristics on any of the versions.

Another thing about the earliest modules ....and modules before the final 'final' version('s?) ...was that the module could misfire between the two cylinders. Weird, but, yes, it could happen. BMW eventually cured this problem in much later modules. AFAIK, no one has ever reported to the Airheads LIST that they positively determined this was happening to their bike. The reason is that is is subtle and tends to be ignored since it is not continuous for any string of sparks, so might only (my speculation!) be seen on an oscilloscope ....and maybe the bikes had emissions testing anomalies (a further speculation on my part). BMW also fixed the modules so that there was NO SPARK unless the engine was being rotated. BUT: One could obtain one spark per rotation of the KILL switch on and off ...which is handy for certain tests.

Module & coil information IS, YES, quite confusing. I have re-edited this article several times; a major goal was to simplify AND increase understanding. I do not think I have been entirely successful, because I also wanted ALL the information here, and there is a LOT of information. I suggest you read all the following paragraphs on this subject ...to complete your understanding.

Here is information that you may want to at least glance at, for your understanding of the last generations of the electronic ignition used on the Airheads:If the module has white or pink lettering, it is only to be used with ignition coil

12-13-1-243-910. This applied to all engines BEFORE 1991. If the number on the COIL is 12-13-1-244-426, then you need the latest upgraded module. Early & later modules use the same part number! The last of these two modules have turquoise lettering, and that module is usable with all the coils, including the last coil, 12-13-1-244-426. Turquoise, in case you do not know, is a light green, slightly blue-tinged. Interesting, at least to me, is that these modules seem to have all been made by Telefunken in Germany, and not by Bosch. The very last module, usable with all the coils, has the turquoise lettering. But, it came in two versions:

12-14-2-325-284

12-14-2-325-550

One of these two will fit your bike ....because the only difference is the mounting. A possibly confusing issue is the number, 12.14 - 1 244 477, turquoise, on these late models, so read this entire section, well downwards ....INCLUDING 2. and 3. where information from OAK is located (and MY comments too).

HINTS!!

A problem, not so rare, that does not apply to earlier models, & not to two coil models:

If your bike is difficult to start you may have a problem with the early version of the Ignition Control Module. Versions of these that had the problem are coded by paint markings, of PINK ...or WHITE. The final updated module is the above noted 12-14-2-325-284 ...with turquoise paint mark as noted, but some bikes had the other style of mounting, using module 12-14-2-235-550.

If your bike has a hard-starting problem, or only one cylinder operates until it warms a bit; & you don't want to try $$$ things (such as to install a new pricey module, nor an aftermarket one ...which won't have the latest trick changes anyway)...you can try a NO COST trick. When your bike is not starting immediately, then SHUT OFF the ignition kill switch on the handle bars, then turn it back on immediately; and then try starting the bike. This is not well known, & to my knowledge Oak never wrote about it.

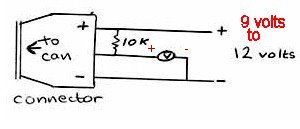

Nerdy: There is an interesting way to determine the 'time' for cutting of coil current (assuming it does happen, which is possibly questionable on early modules), not that this actually means much to you. Watch the fairing voltmeter. If no fairing voltmeter, attach such, temporarily, someplace. The indication may work more clearly if connected to the ignition switch output rather than the battery, but try the battery first, because it is usually easier to connect a voltmeter there. You can also get fancy & monitor the proper terminal at the module, see the schematic further down this article. From the instant of key-on, the voltage will drop a bit showing an electrical load has been applied ....& may continue to very slowly drop a small amount more. Note the time from the initial small drop TO where the voltmeter gives a SMALL JUMP UPWARDS, ...it is usually quite noticeable. That is the timer interval.

Due to changes made by BMW, & confusion over the many issues, I had already begun to do testing and already had greatly expanded the above area & the next long section about modules, when I found that Oak had found time to move faster than I had with SOME of the testing, etc. Below I am printing his commentary, as published to the Airheads LIST on May 11, 2011, edited by me for clarity. I have NOT included the information Oak published in November 2011 AIRMAIL, since I have already covered it in this article in my own way. Oak posted much further back...on December 6, 2003 ....some of the same information. I used to have that information in this article, but have dropped most of it, as Oak's May 11th, 2011 & November 2011 information is better. You now also get the benefit of all my own information & interpretations! As you can imagine, Oak and I had a lot of conversations during the testing and research work we both did.

From OAK, May 11, 2011 ....edited for clarity by Snowbum:

First is Oak's May 11, 2011 commentary (snowbum has slightly edited Oak's comments to clarify which part Oak was talking about, and, certain specific Snowbum comments are in red color for extra clarity):

"The ICU (MODULE) version with the heat sink riveted to the ICU is BMW's very latest. The part number is 12-14-2-325-284. It is now BMW's standard replacement part for ALL models from 1981 forward; has ALL the updates; is applicable for both the kickstart & non-kickstart models. The ICU comes now with the aluminum heat sink attached & is NOT meant to be serviced by removing, cleaning, & installing fresh heat sink paste, as were prior NON-riveted versions."

There were SIX prior ICU versions previously used, with the following part numbers; these used a SEPARATE heat sink (that is, the module was not riveted to a heat sink, but bolted/screwed). These types require cleaning & fresh heat sink compound every couple of years. ALL of these are now obsolete, no longer available from BMW.

12-14-1-244-089---Non kick start version circa 1981 thru 1983

12-14-1-244-191---Kick start version circa 1981-1983

12-14-1-244-226---Kickstart version circa 1983 and later

12-14-1-244-481---12-14-1-244-482, from mid 80's up till about 1987-1988.

12-14-1-244-477---Kickstart & non-kickstart version up till about 1988. Could replace all previous versions.

You will find all those numbers are no longer listed in dealership on-line fiche. See Snowbum's further remarks, just below:

Snowbum says:

That last one, 12-14-1-244-477, has been seen with the BMW Emblem printed on it; the part was made, and so-identified, by Telefunken of Germany. The printed part on it is printed on it this way: 12.14-1 244 477, and all the printing is in turquoise. That is the new module, & you probably will find you have the 0.5 ohm primary winding coil, marked Bosch 0-221-500-203. Approx 12.4K secondary. Contrary to any interpretation of the information in the prior paragraphs, this module has been seen installed by BMW up to the last of the bikes, made in 1995, and is the NON-riveted construction type. Typically, you will see this heat sink of the type that fits on the right side of the frame backbone. NOTE also, that with BMW's change to the one only type of heatsink, there are a few small parts you'd need (see the dealership fiche) to mount the module assembly on bikes that previously had the module mounted on the flat area under the tank ...and I do NOT mean on the right side of the frame backbone. (If you want to demount the module, and mount it on the old area, that's OK with me). I recommend that if you really need a module, you purchase this one, ONLY! This is because it solves ALL the problems, and fits, and will work with ANY of the coils, even the aftermarket ones.

There were THREE heat sink design version changes. ALL are obsolete and no longer available from BMW.

12-14-1-244-087---First one, in 1981

12-14-1-244-192---For kickstarter ICU's circa 1982/1983

12-14-1-244-328---Post 1983 supposedly for use with kickstart or non-kickstart models. The casting, rare for BMW, has the actual part on it, and the part is shown this way: 1214 - 1244 328

Why all the changes to the modules (and, heat sinks)? There are multiple reasons:

a) The earliest design, 12-14-1-244-089, provided almost 2 seconds of time for coil current to flow while cranking the engine for starting. If the starter button was not depressed in time, the ICU would shut off the coil current off to prevent spark coil & ICU overheating. There was a reset time needed which now & then caused starting problems. This created more than enough reason for an update.b) There was a kickstarter version 12-14-1-244-191 to delay spark current cutoff for up to 5 seconds to accommodate the slower use for kickstarting. Replacement choice required care to make sure the correct unit was fitted. For this version there were some problems. It was superseded using the 12-14-1-244-226 later design circa 1983 or 1984.

c) There were other relatively short lived ICU's that followed, without any explanation.

d) Another problem arose. Many of the later mid 80's models exhibited difficult starting, frequently firing only on one cylinder. Sometimes it would start easy, sometimes with difficulty. The problem was eventually traced to the failure of the ICU to determine when it should fire for both cylinders all the time always on the power stroke. Sounds strange to those that know the Airheads have a wasted spark system!; but, BMW crudely explained this as a loss of synchronization. Some users reported needing to place the KILL switch in OFF then back to ON position to re-arm the ignition; then it would start. (see Snowbum's ...that's ME ...HINT comments earlier).

This problem was followed up with another re-design of the internal electronics of the ICU with a change again, this time using 12-14-1-244-477 for both the kickstart & non-kickstart models, obsoleting all prior versions of the ICU. Keeping the same part number, it was explained that if a new unit was installed, to make sure it had a turquoise paint color identification to insure the replacement unit contained the redesign.

What follows to the end of this entire section, to the black line, is a combination of Oak's and Snowbum's comments.What they had done is to re-design the unit so that NO current would flow UNTIL the engine was rotated, such as with the starter or kickstarter. That avoided the ignition-on, not starting, overheating problem, entirely. (Snowbum still wonders why BMW never did this in the very first module design, as it seems obvious). The turquoise painted version was capable of handling the higher current required by a " souped-up" much improved ignition coil, and incorporated the new more reliable sensing of timing pulses, etc. Snowbum and Oak disagreed about this interpretation, as Snowbum did tests on some early modules, and knows that some modules shut down if the engine does not rotate within a second or three. CONFUSED?

e) BMW also had problems with ignition coil failures (the earlier gray-colored-plastic single coil with two towers from the early 80's onward). The black Bosch single tower coils (installed in pairs) of the 81 thru 84 models are OK and work perfectly. The gray plastic shell twin tower coils would crack & develop open or shorted windings. It often showed up as a problem in rainy conditions; but also often in any conditions. BMW decided to finally fix that problem with an improved coil. There were two generations of later single coils (with the twin towers). The first replacement was no longer a gray color. Some folks used the Oilhead coils, which were not difficult to mount properly. BMW eventually installed the 1991-1995 type coil, often called the Red Coil. It had a rather low primary resistance, ~0.5 ohm, sometimes described as 0.6 or 0.7 ohm. The secondary was approximately 12.8K ohms. These also provided a more powerful spark, with a lowering of primary resistance to permit a higher input current. The coil can be retrofitted to earlier models but would require the latest in ICU (module) design due to the higher current need. It is necessary to use the 477 suffix ICU part number with turquoise paint code, or use the very latest ICU (with the integral riveted heat sink--part 12-14-2-325-284) which OBSOLETES ALL PRIOR VERSIONS. BMW warns, rightly-so, that you must NOT use the updated coil on ANY of the older ICU's unless the ICU is coded with a turquoise paint dot. If you do use the new high power coil on an incapable older ICU, it will cause overheating of the ICU and very likely cause it to eventually fail.

There are only TWO module assemblies now available from BMW; 12-14-2-325-284; and 12-14-2-325-550. The differences are the mounting. The latest ICU with riveted-to-heat-sink construction, for use on the right side of the backbone, should be factory equipped on all Airheads, 1988 & later. It is fully updated & will handle the new high current hot spark single coil with dual output 12-13-1-244-426. That coil should be on all 1991 thru 1995 models. You may need some of the mounting hardware to retrofit the latest ICU & coil, depending on year and model. The Telefunken 477, turquoise, is THE module.

Some words of caution involved with use of aftermarket ICU's (modules): BMW took a long time to get their act together on ICU & coil updates. Some aftermarket ICU's will work ...or; may not. They all have the same terminal coding which apparently is standard ...but that is where the similarity may end. The internal designs have been upgraded a number of times. If you use an aftermarket module, that is your decision. The cost savings may be considerable. If it works OK and LASTS;..... you won!

Note my comments regarding the modules with turquoise printing ending in 477.

COILS ...PART 1:

There is plenty of confusion about coils. Some of literature is wrong ...or misleading. One of the various problems is that coils may not be marked, coils may have BMW numbers on them, coils may have Bosch numbers on them. People also do sometimes purchase coils that are not original factory equipment.

BMW coil 12-13-1-351-584, is Bosch 0 221 100 022, used on the /5, a points model. No longer sold by BMW.

BMW coil 12-13-1-243-452, is Bosch 0 221 101 003, used on the POINTS MODELS, in the /6 and /7 era. It replaces the above coil for those years and the /5 too.

Both of these coils are 6 volt coils that have primary windings of about 1.5 ohms each, and two are used in series connection for the primaries, paying attention to the polarity markings (+ and -, and sometimes 15 and 1). It is possible that some literature will say that the two above coils are the same. For practical purposes, they do interchange. These early coils had secondary windings of ~6.5 to 7 K ohms.

Do not confuse points coils with certain 1981+ bikes that had two 6 volt coils & were used with electronic ignition. These had primary windings of ~0.67 to 0.77 ohm. They have a lightning bolt symbol. If you used these lower primary resistance lightning bolt coils with points, the points would not last long. Example is the BMW coil 12-13-1-244-142 which is Bosch 0 221 100 028. Some call it the Lightning Bolt coil. Some literature will refer to 12-13-1-243-142, but there is no such real number. Literature may refer to it as the 1981+ coil with 0. 5 or 0.7 ohms as Bosch number as 0 221 100 313. You will find all this confusing! The main thing to know is that you must not use fractional ohm coils with points. You must not use the lightning bolt 6v coils with a points system....unless you have a specially modified booster/amplifier.

The electronic ignition models began with model year 1981. Because the model year begins in the prior year's September production, some literature might show or imply a points coil being used for a 1981 model year bike, or a 6 volt electronic ignition coil being used for a points bike, for 1980. Other literature, including some on-line-fiche, may, more properly, show 09/1980 as the changeover date.

Electronic ignition models: The original troublesome gray-colored twin tower single coil tended to crack; fail intermittently; usually eventually totally failing, but initially usually failing when damp/wet. The troublesome coils were used on various models including the R45, R65, R80GS, R80ST. The OLD coil was BMW 12-13-1-243-910. That coil is for pre-1991 engines and had a 0.9 ohm primary and 12.8K secondary; control units (Modules) with white or pink lettering are used with it. The very latest modules can be used with any of the coils. The -426 coil is similar to the 12-13-1-243-910.

Be very cautious if mounting the Bosch "blue" coils ...they can interfere with the fuel tank.

COILS ...PART 2:

Coils can fail catastrophically, or bit by bit; or, even have a sudden slight failure that remains. IMO, for most failures, failure is bit by bit until you seriously notice problems. Coils can act 'weak' if they have an internal wire breakage. A wire breakage is detectable with a simple ohmmeter test. Coils with a break in the secondary windings can still seem to work OK ....although may give strange engine power output effects, particularly with large amounts of throttle, which cause higher cylinder pressures and thus more coil power is required to jump the spark plug gap. The reason that coils can work (maybe); or get weaker with secondary windings having an actual break in the wires, is that the same voltage firing your spark plugs is also jumping across the broken coil wire! You might never notice, until it gets bad enough, typically by jumping to more wires nearby, or widening its broken wire gap.

Ignition coils with an internal short circuit (usually that happens between adjacent turns, or between two close layers of windings) can seem to work OK, but, as with some open's, the spark is weaker; this can show up as what might initially be thought of as a lean-running engine problem ...or, just shows up ...such as with large throttle amounts ...as reduced performance. In almost every instance, a shorted winding happens on the secondary winding, as just a turn or two problem ...or between two adjacent winding layers. These change the coil electrical resistance value by a really miniscule amount, so is not detectable by using an ohmmeter. One could compare a good coil versus a bad coil, using the A.C. transformer method or with an oscilloscope, but you are unlikely to have the needed setup ...and knowledge. Additionally, it might only show up when the coil is under actual stress of operating the engine. If a coil secondary OPENS & remains open, that certainly IS detectable by an ohmmeter. Except for weak spark or MANY turns of shorting, or an actual wire being OPEN, there is NO common simple method of coil testing until things get quite bad....EXCEPT that if you have experience, and own an oscilloscope and appropriate pickup coil or other connection means, you CAN determine that a coil is bad. With battery powered oscilloscopes being available for 'reasonable' cost these days, it is possible to even do testing out on the road (don't look at an oscilloscope where others are traveling, lest you have an accident). No, I have NOT (I may, sometime?) shown any sketches of what the good waveforms versus bad waveforms, will be.

When an ignition coil of any type fails, it often happens little by little. Coil failures are perhaps 99% more likely on the secondary high voltage winding. Due to the high voltages involved, this, usually, slowly leads to additional such failures, & as they accumulate the coil output DEcreases.

The Airhead coils have a large capacity for our modest to medium-high compression 2 cylinder engines that hardly top 7,000 rpm, so some things can deteriorate a LOT before you notice a problem. Depending on the type of failure, you may have poor starting; this can happen both with a cold engine & a hot engine; you could have very poor ignition at higher rpm (and/or large throttle amounts) ...with stumbling, even backfiring sometimes.

Damage to coils is often done by owners, or even by some shops, by removing the spark plug caps from the spark plugs while the ignition is powered. This usually happens during carburetor synchronization. IT IS A BIG NO-NO to pull off the cap. The damage, if it occurs, may not show up immediately ...it can suddenly show up years later after enough heat/cold cycling. Damage typically occurs with the engine running ...but damage can occur as the ignition is turned on, caps off. The spark plug caps need to be grounded, via the INternal cap contact; usually done by having the spark plug attached, and the spark plug metal body is grounded to a cylinder fin or the cylinder head. Lifting the caps with the key-ON for such as carburetor synchronization is a big NO-NO on Airheads. It was acceptable on the old magneto models, pre-1970, which means BMW bikes before the /5 series, as they had a 'safety gap' structure. BMW themselves erroneously carried over /2 era advice on lifting spark plug caps into the Airheads era & you may see such in some owner's booklets. DO NOT DO IT! IMO, it should NEVER be done on ANY engine. You might see such erroneous advice from BMW re-printed, again and again, in such as owners booklets and Clymers and Haynes repair manuals!!

All sorts of failures have been seen numerous times in the various coils ....with a few types of failures specific to certain coil models. As I noted earlier, the early 12 volt twin-tower coils were infamous for the gray plastic case cracking. These coils, sometimes not so nicely called Crack-O-Matics, were first seen on the original R45, R65, R80ST and R80G/S motorcycles. The case cracking could break wires in the secondary winding, often giving a weak spark, which could continue to deteriorate. The crack would usually allow moisture to get inside, completely or almost completely eliminating the spark ....and the coil might not allow starting the motorcycle, or it might allow the engine to run very poorly. In some instances, drying the coil THOROUGHLY, & filling the crack with a non-metallic epoxy sealant or glue, could allow a 'wet' tour to continue until the coil could be replaced. Oilhead coils or coils from another brand were sometimes used as a replacement for these old twin-tower coils.

Contrary to comments by some, it IS possible for two-tower 12 volt coils to fail in such a way that ONE cylinder works pretty well, and the other cylinder misfires or hardly fires at all. Reversing the coil tower coils will reverse the effect, that is, the cylinders are now reversed in which one is not working properly. This effect has been seen in failed stock two tower coils as well as failed Dyna coils. Usually an ohmmeter test either shows an open circuit for the secondary winding, but not always. Usually grounding is not the problem. The best test is a substitute. If the bad cylinder and good cylinder reverse, it is almost always the coil that is the problem; but there have been instances of module problems, as previously explained.

GREEN CORROSION in coil towers:

Any coil tower, single or dual types, can get green corrosion green colored corrosion in it. Remove the spark plug wire, look deep inside the tower. This is usually from small amounts of moisture getting inside the coil tower, perhaps from a poor rubber boot. Sometimes it happens from wires not fully seated, which allows sparking ...and oxygen and sparking are not nice to electrical connections. The green is a chemical reaction from the copper in the brass connectors. Once in a while green corrosion can allow the coil tower internal metal & the spark plug wire metal end to act like a lousy diode & you could have all sorts of effects, including massive radio noise.

Many years ago, power diodes were made from a form of copper oxide coated plates ....the same thing was also done with selenium coatings. Besides diode-type vacuum tubes [such as mercury vapor tubes], those coated plates were just about the only power diodes available long long ago, and were used with early alternators and in battery chargers, and commonly [in tiny versions] in radios; some were still being used into the seventies.