Pinging (Pinking); Piston Detonation; Lugging; knocking.

Both simple and detailed/nerdy information.

© Copyright 2020, R. Fleischer

https://bmwmotorcycletech.info/pinging-detonation.htm

52

This article will present the concepts of pinging/pinking, knocking & piston detonation, in several ways, including a nerdy section.

Pinging Pinking are the same thing...but Piston Detonation is NOT the same. Detonation, regarding the combustion process, sometimes is called "knocking", but probably should be explained as something different, and then including the sound from excessive bearings clearance from wear, etc., as it is not an exploding engine, as used for such as for explosions. You usually hear the various types of sounds these things make .....particularly the pinging/pinking sound ....as it does not sound anything like knocking. Pinging/pinking is a definite sharp metallic rapping/tinging sound. The sound has been described as a piece of metal being hit by a very small ball-peen hammer. The sound may be just one or two such 'tings', or a slow to rapid series of 'tings', RPM sensitive.

Detonation is a very much lower frequency sound, not high pitched at all. Sort of a quite dull rapping or thudding noise.

The causes are different and the descriptions are different. The results of either being excessive can be very different, or similar in some respects. It is possible for an engine to have both pinging and piston detonation happen, typically the pinging (also called pinking by the British) happens at fairly low rpm under acceleration, ....on an Airhead it typically happens between high idle rpm and ~3500 rpm. Typically detonation happens at high power at considerably higher rpm, and is often harder to hear. Both pre-ignition (pinging/pinking) and detonation are abnormal events, although an occasional one to a few pings usually does no immediate damage, and may come from too low fuel octane for the engine. Pinging can also occur from lean mixtures and/or from wrongly/poorly operating ignition.

Pinging/pinking may often be more accurately described as pre-ignition. Pre-ignition occurs when the fuel-air mixture begins to burn too early with regards to piston travel. Most commonly that means that the fuel-air mixture has been ignited by something other than the spark at the spark plug (because the spark has not yet happened), although it can occur from the wrong spark. By wrong spark I mean that pre-ignition has also occurred in multi-cylinder engines from cross-firing due to electric sparks jumping between a bad, perhaps cracked ignition lead, to another cylinder's ignition lead. For Airheads, pre-ignition usually comes from wrong mixture and/or a hot glowing bit of carbon in the combustion chamber or too low a fuel octane; occasionally from wrong ignition timing. It is not unusual to find more than one cause. Note that if the ignition timing is too advanced, pinging can occur at low RPM, in which case the ignition causes the event.

Piston detonation nearly always is identified as an even that occurs at high power (high throttle setting), and moderate to higher rpm. Detonation is a spontaneous combustion event that occurs AFTER the initial burning of the fuel-air mixture. This means it occurs AFTER the normal spark event. Residual unburned fuel is ignited from heat and pressure. It is possible for combustion to begin normally, and then a second fuel ignition (combustion event) takes place. When the spark ignites the fuel mixture normally, the piston has not quite reached top-dead-center in the cylinder. That is, the piston is moving up, it is close to but not at the top of the cylinder. At that point the spark occurs, the mixture ignites, and the mixture burns relatively slowly. But, if the piston is rising and the additional pressure in the combustion area causes an igniting, or a second ignition after the spark, that is WAY different. You can also think of this secondary igniting as being akin to a diesel engine, which neither has nor needs any spark at all. The secondary ignition can cause a tremendous rise in pressure on the piston, ...and it covers a wide area of the piston surface. It is possible for this secondary ignition to occur from a red-hot piece of carbon deposit. There is a lot of nerdy information about this subject, such as effects of such as incoming fuel charge, etc., but these will not be much discussed in this article. I do get into some additional technical aspects later in this article, but only those that are relatively easy to understand.

In this article are photos of what a engine piston, cylinder and head can look like if there is excessive pinging or detonation, to the point that a hole is "burned' (it is much more complicated than a 'burning") in a piston or the piston top lets go; or, an exhaust valve tulip comes off the valve stem.

An occasional ping is seldom serious, but it is best not to have any. A fast long train of pings is BAD. Same, but often much worse, for fast thudding noises from piston detonation. Many think that pinging is a tiny explosion or extremely fast burning of mixture with its fast rise in pressure, that is at the valve, and the result is a slamming of the valve back onto its seat. Rather than blinding accepting that explanation, you should think about it. How would the valve be able to slam like that, with no clearance for inertia?

Nerdy: pinging can also be a process similar to cavitation bubbles, that hammer away at metal, which happens to boat propellers if they are at too high an RPM.

Photo #1: Piston damaged by too low octane or wrong ignition timing or glowing carbon in the combustion chamber, possibly some detonation. If you think that this looks like the effects of a lot of teensy hammers (surrounding the hole from a big hammer), you would be correct.

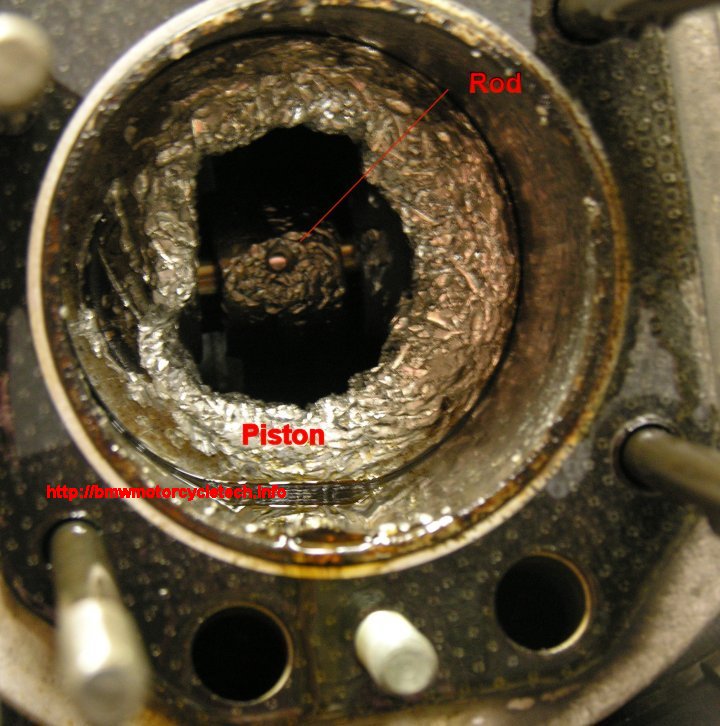

Photo #2: Damage when a valve lets go. The rod end that fits into the piston is quite visibly damaged, through the big hole in the piston crown! This engine will be full of metal pieces everywhere and a teardown and very thorough cleaning will be needed. The rod will have to be replaced. Same for piston and valves. The cylinder is quite likely ruined. If lucky, the crankshaft is OK.

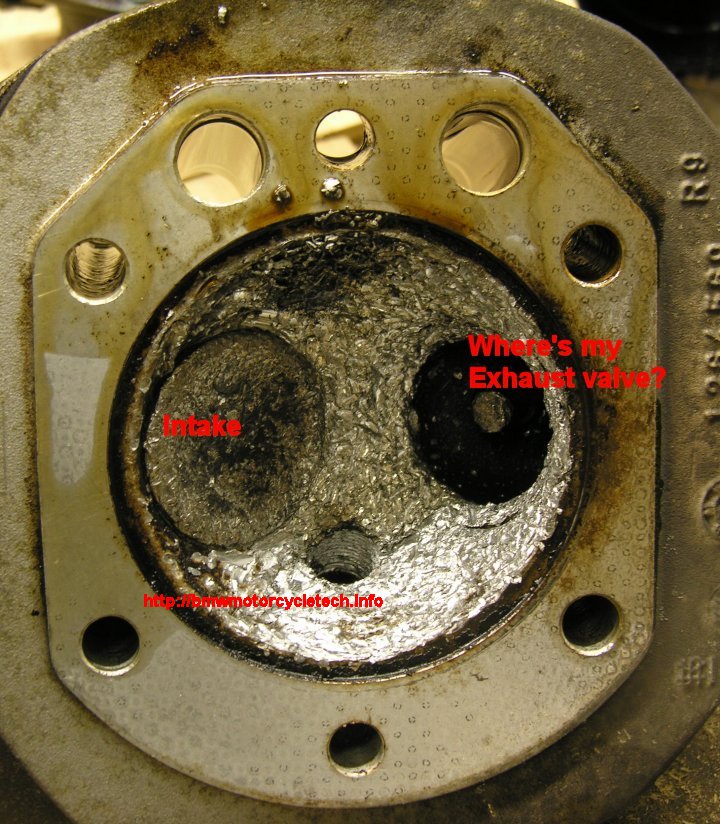

Photo #3: Head damage when things come apart.

For both pre-ignition and detonation, the rise in heat and pressure is very fast. For detonation, generally the entire top area of the piston is involved.

The rise in pressure causes an oscillatory ringing, or resonance as an engineer might call it; the result has been compared to cavitation effects of excessive rpm of a boat propeller. It is as if millions of tiny hammers are banging away at the metal surface. The result can be broken pistons, broken rings, pitting of piston crowns, & overheating. Areas of special concern are the thinner metal on the side of a piston, and on the piston crown, because it is not as close to the cylinder wall as the part of the piston just a bit further down. For those who do not understand that, the piston diameter is slightly smaller at the upper ring area, so it does not radiate heat to the cylinder as well as do the lower parts of the piston. Pressures can be enormously high and affect rods and bearings. You can have broken spark plug insulators. In some instances, an excessively hot heat range of spark plug has caused premature ignition problems or the initiation of detonation. Detonation can be caused by overheated valves, as well as from other causes. The combustion gases could actually reach 1800°F. The excess heat is only partially removed by the exhaust gas exiting the cylinder; the remainder, which is considerable, will overheat the piston, valves, head, etc., and tends to be additive as time goes on. As things progress, all sorts of nastiness increases in possibility.

Both types of effects can be lessened, perhaps totally eliminated, by running rich mixtures and/or higher octane fuel. It is actually possible for detonation to not occur at wide-open-throttle where the carburetors may run quite rich in operation, yet detonation could occur when the throttle is backed off slightly ... and while that is somewhat unusual, it does happen.

There are instances where an excessively hot heat range of spark plug has caused problems ...with both pinging and piston detonation. Of course, if the spark plug heat range is considerably 'too hot', the spark plug central white ceramic insulator could crack and break off, causing damage to the engine.

In strict terms pinging/pinking/pre-ignition occurs BEFORE the spark occurs. In common usage however, it can also mean the effect from much too early a spark. Mild pinking does not generally produce immediate damage unless continuous. Almost all modern cars use ping detectors, and when pinging or knocking is detected, the engine is automatically adjusted, usually the spark timing is retarded (as a minimum compensation), to reduce or eliminate the problem. BMW Airheads and Classic K bikes do not use knock detectors.

Oftentimes, pinging occurs with a bit too much throttle in the rpm region where the ignition has just reached, or nearly, full advance. For the Airheads, that typically means pinging with a bit too much throttle for the ignition timing is more likely, especially with low octane fuel, in the area of 1500-3000 rpm. For /5 airheads with the original ATU (Automatic Timing Unit) which reaches maximum ignition advance at about 2000 rpm and the higher compression ratio as originally shipped by the factory; and, especially, in combination with lower octane ("Regular grade") fuels........... pinging/pinking is more likely with a goodly amount of throttle being used below 2500 rpm. This is as opposed to the later models with the ATU change to 3000 rpm for maximum advance, which have less tendency to ping in the rpm area. In 1981 and later, Airheads came (in some countries, such as USA) with lower compression ratio, decreasing any tendency for pinging. This enabled use of less than premium or super-premium fuel, but power output suffered. In the years of the /5, /6, and /7 motorcycles with higher compression ratios, higher octane fuels were available in many countries, that quite adequately mostly eliminated pinging and detonation ....but not all countries had it available, thus compression lowering 'plates' ....metal gaskets...were used at the cylinder bases, but at the cost of some power output.

A treatment of pre-ignition and detonation with regards to automotive engines, but pertinent to our motorcycle engines, discusses things in more depth in some areas, here:

http://www.contactmagazine.com/Issue54/EngineBasics.html

The writer also is not addressing your Airhead's type of combustion chamber and older engine design. Thus, when the writer claims no damage from pinging (well, detonation) events in certain areas of the article, please mostly disregard that for your Airhead engine or classic K-bike engine.

This entire section is for the nerdy...maybe even very nerdy!

A knocking or thudding sound (not the sound from worn bearing shells) is when uncalled-for pressure on the piston top is of very short duration occurs ...a pressure spike. It occurs from sound waves, as the piston approaches TDC, and the noise is due to these pressure waves pounding the combustion chamber, the piston top, etc. It is NOT due to colliding flame fronts or flame fronts striking the piston or cylinder walls. With ignition by the spark plug, a pressure wave begins, and travels fast, through the portion of the unburned fuel-air mixture, AHEAD of the flame front. Flame front speeds are around 50 cm/sec ...quite slow compared to the speed of sound, which is about 300 m/sec. The speed of the flame front propagation is actually faster, due to the mixture turbulence ....the flame is moving in all sorts of little patterns. Look up the Eddy Burning Model, by Blizzard & Keck, of 1974. Getting even deeper into nerdiness, the flame front surface has a fractal nature, increased greatly by the turbulence, so the flame front surface area is increased. The result is more mixture exposed to the larger flame front surface (Fractal burning model, Goudin, etc., 1987). Wonder how we know? ...well, in the earlier days, we saw the various described effects via high-speed photographs taken through a quartz window of a modified engine. These photos are called Schlieren pictures ....and show all the stages of the combustion process ....including the flame front propagation called the Kernel. A higher degree of turbulence ...and thus higher effective propagation velocity ...can be achieved with the Squish-Band type of combustion chamber design (used on some early BMW Airheads). There are other ways of getting desired effects, such as designing the combustion chamber shape, so that the incoming mixture is swirling. The over-all goal is to increase the burn rate of the fuel-air mixture.

Pressure rise is usually about 20 to 30 psi per degree of crank movement ...and once higher than ~35 psi per degree, the engine will run rough ....due to mechanical vibration caused by too fast a pressure rise. If the pressure wave is strong enough, the fuel may self-ignite.

Whether or not the fuel ignites before the desirable point depends on MANY factors, including fuel composition, but even high octane fuels can self-ignite, as described. Helping (?) things along towards very undesirable detonation, is that as pressure in the cylinder increases, that pressure rise causes a temperature rise ...common to any compressing of air, etc.

When detonation occurs, it mostly begins at the pressure wave's point of 'amplification', which is at the edges of the piston crown, where pressure waves of various types and areas in the combustion area will tend to combine ...which actually causes an increased pressure at the contact point. If the speed is faster than the speed of the fuel-air mixture burning, then pressure waves from the ignition spark plug area and the problem places will, combined, cause mini-explosions, instead of combustion ...this leads to more pressure waves and more problems (havoc!). The colliding pressure fronts meet, the destructive power, really is Shock Waves ...is onto the engine parts, and you may have serious motor destruction.

Here is a brief discussion of Boundary Waves. I suggest you read very slowly:

These are very thin layers of fuel-air mixture, at or just above the metal surfaces. Normally (why is even beyond this article's nerdiness) the boundary layer is close to the metal surface, thin, perhaps a tiny fraction of a millimeter thick. It is in contact with relatively cool metal, so the boundary layer does not burn by the contact of the flame front. The layer can be swept away by the high pressure shock waves of detonation. The piston top, in particular, is now exposed to the flame front. The temperature rises in the aluminum piston top ...you can guess the result!

Around 1990, computer simulations began to get so good that radically new understandings of the combustion process came about. This had quite an effect on engine design ...which is, in a way, a problem of thermodynamics. All sorts of exceptionally nerdy things were now being understood. Eventually, use of exceptionally powerful institution-type of computers led to near 100% complete understanding.

LUGGING (of all types):

One cause for both pinging and/or detonation is called Lugging. Lugging can cause serious & even sometimes rather immediate damage. There is no absolutely totally agreed-upon-definition of lugging. I will give you mine.

If you increase the throttle, and rpm and speed does not increase, or does so very sluggishly (or even DEcreases), you almost for sure have been, or are now, lugging the engine. Some might add to that idea a second requirement: you cannot reach yellow or red line rpm in that gear, no matter how much throttle. Manufacturer's almost always have gearing such that you can not reach redline rpm in top gear, even at sea level, on a good surfaced road. Thus, the top gear may sometimes be thought of as 'an overdrive', as the top gear ratio was likely selected for fuel mileage, wear, noise, etc. I think all these definitions are good, but the first one is primary. If you cannot accelerate, and must drop down to a lower gear to raise RPM, thus raising horsepower, then you were lugging; but, often, but NOT always, this is not a problem situation when you are maintaining a reasonable speed on a highway with light throttle, and neither gaining or loosing speed.

Lugging is likely possible with nearly any type of engine, no matter how modern, although it is less likely to be seen with modern automatic transmissions, which usually will 'kick-down' to a higher gear ratio, even without hard pushing of the throttle to 'force' the transmission to shift downwards.

I will restate the above in a different way. An example of really bad lugging might be if you tried to ride your Airhead motorcycle up a hill or moderate upslope, at 2000 or even 4000 rpm, perhaps even higher rpm, using moderate or lots of throttle; ......and you increased the throttle and got little or no effective acceleration. As you continued, the piston will heat up more and more, as will the engine. You might well experience detonation, and very well might not hear it! ...and the engine might fail disastrously; this is especially so if you continued the lugging. Lugging is usually thought of as a moderate rpm situation with heavy throttle. Lugging can be done on automatic transmission cars, but it is harder to do in such as "Drive" mode, as the transmission will either shift by itself; or, if you push the throttle too far to where a mechanical or electric method is employed, the transmission will then shift into a lower (higher ratio ) gear. Another way of saying this is the transmission will automatically shift downwards under even moderate+ throttle position, if rpm drops too much.

The problem with 'lugging' is that cylinder combustion pressures go quite high, perhaps extremely high, and a lot of heat can be, and usually is, developed. A hundred or so extra degrees of heat on an exhaust valve is actually a fair amount, and two hundred+ is A LOT. The pressure and heat is increased, and the amount of time that these two are increased is lengthened, thus the cooling provided by the exhaust valve closing and transferring heat from valve to exhaust seat, is reduced. The cylinder head heats up, the exhaust valve heats up, and even the intake valve heats up some. Not only are the valves affected, but lugging is usually harder on the rod bearings. If the lugging is done at low rpm, the bearings will be, in essence, starved for lubrication for complex lubrication reasons. Bearings need proper rpm, surfaces speed, and oil flow for lubrication AND COOLING protection. A treatise on how lubrication REALLY works is on this website.

https://bmwmotorcycletech.info/oilessay.htm

Another type of lugging needs to be discussed here. This one is hardly ever described as lugging. It is when a fair amount of throttle (usually, but sometimes only quite moderate) is being used at quite modest rpm, and one hears a metallic pinging noise from the engine. Americans call this PINGING, the Brits call it PINKING. It is commonly the result of too low octane in the fuel for whatever the engine tuning and condition happens to be. That can be thought of in another way, meaning that an engine that runs fine if in proper adjustment can make such noises if the engine adjustments are wrongly made or compression ratio too high for the gasoline quality, etc. Most Airhead engines have a potential pinging "zone" from idle rpm to maybe 4,000 rpm. Pinging/pinking is ALSO quite affected by ignition timing and piston speed, gasoline octane rating, and altitude (particularly carbureted engines), and is one of the several reasons that car engines generally have an automatic ignition timing device that is more complicated than the ATU in Airheads. For the Airheads, the ATU (Automatic Timing Unit) is located inside the ignition control area on the front of the engine. Except for the earliest /5 Airheads (where at 800 rpm ignition advance begins ...yes, at slow idle ...and 2000 rpm gives maximum advance), our later /5 and /6 and later Airheads ATU's start advancing the ignition at about 1500 rpm and quit (that is, reach maximum) at about 3000 rpm.

Pinging is less likely if you are riding at high altitude, because of less combustion chamber pressures AND that the mixture enrichens some...richer mixtures have a cooling effect. The Bing CV carburetors have less change, but the change is still quite noticeable.

Occasional transient pinging/pinking is not very dangerous to the engine's health, but it DOES accumulate its effects over long periods of happenings ....and time. If the pinging is relatively constant, for a period of time, that is BAD for the engine, and BAD things can happen fairly quickly. Keep in mind that pinking, or pinging, is really HAMMERING of some sort. Some old ways of thinking about it are tiny explosions in a small area of the combustion chamber, but these are not really correct, nor are the valves hitting the seats.

A final type of lugging is very serious; generally the damage happens quickly. This effect is called detonation, or piston detonation, & is not an explosion in the way the word detonation is typically used in life (although if the piston collapses it will look something like it). This lugging phenomena is caused by extreme pressures in the cylinder. It is NOT a tinkly metallic sound, but more of a slightly bright (or not) thudding. It is almost always harder to hear than pinging due to its lower frequency tone, coupled with the fact that you are usually at speed with its aasociated wind noises. Detonation can happen from a faulty ignition system, but that is not something overly likely, particularly in an Airhead. Detonation is a sudden burning of the fuel, typically caused by the compression itself, like in a diesel engine. It can happen so early in piston movement (well before top-center) that the pressures that come about from the sudden burning are ENORMOUS on the piston top and rod, and if prolonged, the piston can collapse or disintegrate, usually at its weak area, such as the center of the dome, but this depends on the piston design and a few other things.

If an exhaust valve looses its head, VERY serious engine damage is HIGHLY likely to occur quickly. BMW exhaust valves are very well made, of high quality two-piece design, and seldom fail ...but there are limits to metallurgy if one abuses the engine. There is a mathematical formula that equates exhaust temperature versus the pressure in the cylinder, and other such stuff ...but I think I'd REALLY be getting nerdy to show and describe it here. Most people's eyes roll up into their heads when mathematics is involved. I have seen serious engine damage from lugging. One particular instance, because I am aware of all the details (from talking to the rider and inspecting the engine some), occurred from the rider (on a R65), heavily lugging the engine over numerous miles on the same modestly steep upgrade, in this case, the road grade area was south of Bakersfield, California, and is called the Grapevine if you know the area .....where the road rises up into the mountains. The 65 particularly does NOT like to be lugged, because the exhaust valve stems are smaller than on the larger engines, so heat is more difficult to get rid of. For those questioning this idea, perhaps because the engine is smaller than, say, a R100, and develops less heat over-all anyway, do keep in mind the simple mathematical calculation for area of a circle (the circle being the diameter of the valve stem).

A = π r²

This simple formula shows that a small change in diameter (well, radius) makes a large difference in heat dissipating area. Thus, the smaller valve stem has a much less AREA (per length) inside the valve guide to dissipate heat. Since folks hate the math, so I will do it for you. The area of a R45 or R65 valve stem cross-section is calculated by me using a nominal 6.95 mm stem. That gives an area of 37.9 mm. For a R60 and R100, etc., the stem is 7.94 mm. Yes, just about 1 mm more ...seems like not much difference. But, the area is 49.48. The difference is over 30%! Lest someone bring up the subject of a smaller heat output of the engine, sorry, but the temperatures in the combustion chamber are the same for proper combustion. Lest someone bring up the smaller valve size, well, that needs another calculation, due to the head contacting diameter being smaller. Again, the same sort of calculations will show that heat capture is higher, and dissipation is lower. The bottom-line is DO NOT LUG engines, especially a R65.

PINGING (pinking) .....a bit more ...and some things about ignition, fuel, etc...

Pinging noises on Airheads usually happens mostly with the R50/5, R60/5, R50/6 and R60/6 models. It can happen with any Airhead, particularly the early high compression engines, not just those. The reason that these four models are far more likely to exhibit pinging is that the EFFECTIVE DYNAMIC pressures are high, due to a very mild camshaft. At the other extreme, it is far less likely to happen with the low compression engines from 1981 (esp. USA models). The information below may be of help, no matter the model, year, etc.

While wrongly set ignition or an ignition system failure of some type can cause pinging/pinking, more often the problem is caused by two things, either, or both. First in cause is usually the use of lower octane fuel than the engine was designed-for. Secondly is carbon deposits that raise the compression ratio and/or create hot glowing places. Pinging is heard as a metallic ping or tink or ting noise, one or multiple times, typically below ~3,500 rpm. The gasoline mixture is burning before it should, creating teensy localized fast-burning mixtures, especially common at the exhaust valve area. The gasoline mixture may have been ignited by glowing carbon in the combustion area or from an advanced spark, or even certain combinations with slightly lean mixtures, even wrong spark plugs or weak ignition. A somewhat lean mixture definitely promotes pinging. Some very interesting noises can often be heard if the mixture is too lean. Misfiring can cause excessive richness on the next power stroke, and a large sudden rise in pressure.

Back in the seventies and also considerably before, gasoline's over 95 American Rating System (R+M divided by 2) were very common. Today, it is difficult to find over 91 octane. Most of the early Airheads were designed for 98 octane fuel (American method). Some Airheads came with, or were modified with, compression lowering plates under the cylinders; some had higher compression ratio pistons than others; and, in 1981, for the USA, the pistons were modified for lower compression ratios. BMW increased the CR later, to about 8.8, due to small changes here and there.

If one modifies an Airhead engine for dual-plugging, one can use higher compression ratios. That is often considered as part of converting to dual-plugging, such as on the 1981+ R100 models. Conversely, dual-plugging can reduce or eliminate pinging on stock compression ratios, and that is especially applicable to all the early models, already having a fairly high compression ratio as noted above.

There are two methods of setting dual-plug engine ignition timing (discussed on this website in the dual-plugging article) and those have an effect on pinging. If you are nerdy, you can use the information in this article, especially the nerdy sections, and figure out for yourself why dual-plugging is so effective at the low end of the RPM range.

Some will try to reduce pinging by retarding the spark timing. That can work or help sometimes, but at the cost of engine performance; and in some instances the heat production can increase. 3° retarded from stock is nearing the limit without problems. Note that these comments relate to single spark plug engines ...not dual-plugging conversions ...well, not exactly ...you could use an even higher compression ratio, and retard the spark a bit .....which is needed on some conversions, and does not increase heat on them ...see the dual plugging article regarding the two methods of timing ...stock ATU and timing at OT mark; versus limiting advance maximums and timing at stock S marks, and think what this all means. The following article explains it in much more depth, and, perhaps, easier to understand: https://bmwmotorcycletech.info/dualplugging.htm

The need for higher octane is the primary problem, and this need is more pronounced at lower elevations, as the atmospheric pressure and the oxygen amount is higher, pressures developed in the cylinders are higher, power output greater, etc. The effects of air temperature is also a factor. If the fuel needed is not commonly available, then you really do have to think and consider, and think again.

Carbon buildup can cause pinging (and detonation) as I have mentioned, due to increased compression and carbon hot spots could be glowing red hot, which can also cause various problems. Many have had problems go away by removing the heads and cylinders and doing a careful carbon removal, perhaps with a bit of cleaning and decreasing of any sharper edges, etc.

Details...details.......details:

The camshaft timing is very mild on the R50 and R60 airhead models. The camshaft timing was modified several times by BMW, with the /5, then the /6, and even the /7, and the changes were somewhat effective. The mild timing tends to make these motorcycles want to ping below 4000 rpm (especially below 3000 rpm) with large amounts of throttle. The earliest of these engines had exceptionally mild timing, and are typically worse for pinging. These R50 and R60 engine'd models had many pinging problems with lower octane fuel (and more rarely, but has happened, when carboned-up, even when using higher octane fuels) because the very mild camshaft timing causes increased dynamic pressures in the cylinders. At sea level atmospheric pressures, the dynamic pressures in the cylinders are higher yet. There is also a nerdy thing going on with the smaller diameter pistons of these models, and speed of flame travel is faster, in every respect including per piston movement time, which means that some areas are increasing pressures more rapidly, before the rest of the piston area has reached peak. Consider this as lopsided burning. This is why dual-plugging is so effective against pinging ...and can actually improve fuel mileage! Conversely, if one does not dual-plug, but enrichens the fuel mixture to 'cool' the combustion event, one decreases fuel mileage. Same, in a quite modest way, for retarding the spark. Obviously, if compression lowering plates are used, the reduced compression ratio will also reduce fuel mileage.

****Hints: If you have pinging with your R50/5, R60/5, R50/6, R60/6, R60/7...and, I probably should really just include all Airheads ....check the ATU (Automatic Advance unit) and be sure you do not have the 39° advance unit. Use of the 34° advance unit will be of benefit to reduce pinging. You can RESTRICT the advance of a 39° unit easily, which is perfectly OK, by using thin sleeves. Be sure your ATU quits advancing at a MINIMUM 3000 rpm, or, better, perhaps 3500. DO NOT use the stock 2000 rpm ATU of the early /5 ...although modifying it with the later springs, and perhaps shaving the weights a bit, is totally acceptable. Be sure the fuel level in the fuel bowl is correct, or very slightly high; and be sure the needle and needle jet are correct, main jet too, etc. If the Bing books show the Euro bikes with slightly richer settings/jettings, try those. Ask on the Airlist. De-carboning and polishing the top end is of help, sometimes a lot. Do not fail to remove any sharp edges in the combustion area. Be sure there are no vacuum leaks where the carburetor fits the cylinder head. Internally insulating the airbox to encourage cooler intake air to the engine can help.

Differences between all the automatic timing units (ATU) are here: https://bmwmotorcycletech.info/ignitionsingleplug.htm

All the Airheads before the USA models changed to lower compression motors (~1981), were designed for leaded high octane fuels. The higher the octane rating of the fuel, the less the tendency for pinging and detonation. Unfortunately, alcohol at 10% concentration is almost universal now in the USA at roadside gasoline stations. Ethyl alcohol leans the mixture, and helps produce pinging (via lean mixture heating), unless the jetting is made richer. This is so even though alcohol is well-known for cooling the mixture (in appropriate richness). If you have to, richen the jetting a bit. This means for idle, mid-range, 3/4 range, and full throttle, as needed. In general, any possible required changes from the stock settings are SMALL. Maybe 10 numbers larger on the main jet; maybe a change in needle jet size (a needle notch is a much larger change), and an adjustment of the idle mixture screw. It can help to set the fuel level in the float bowl to the higher edge of normal. Dual-plugging is often recommended.

Be sure the correct heat range of spark plugs are being used and that the spark plugs are torqued to the correct values. Be sure not to over-torque the spark plugs, which can damage the threads in the cylinder head. I think BMW's torque settings for the spark plugs, in some BMW manuals, & in some aftermarket literature too ...is too high. I think 15 or 16 ftlbs is high enough on threads not treated with anti-seize compound, and 14 on anti-seized threads (standard 14 mm, 3/4" reach spark plugs). If torque is too little, the spark plug may get hotter than intended, and thereby act as a 'hotter' heat range. If too high there is danger of thread damage. https://bmwmotorcycletech.info/sparkplugs.htm

Anything sharp edged in the combustion chamber is suspect.

The ignition needs to be in good condition, as a weak spark can contribute to pinging and other ills, besides wasting fuel. Be sure that the ignition coils towers are clean and shiny-bright inside at their bottoms. Test the coils ...at the very least do an ohmmeter check. A spark gap test is best. Test the resistance spark plug caps too. Do not use resistor spark plugs. Do not use resistance high voltage wire, use stranded solid copper wire ignition cable.

If the spark plug caps measure ~5000 ohms, change them to zero or 1000 ohm types, unless you have radio gear. This change must NOT be done on the electronic ignition models (1981+), which MUST have 5000 ohm (nominal) spark plug caps.

Set the spark plug gaps slightly wider than stock, perhaps to 0.032".

For single plug ignition, set the timing to stock. The important timing point is the maximum advance point, which is the F dot or Z line. When trying to eliminate pinging, you want the idle rpm to be proper too, I suggest 1025 RPM. You absolutely MUST have a timing light to check timing properly. There is some leeway here: Some have tried to set the timing a FEW degrees retarded to stop pinging, and while I am not much in favor of this method, I do not object to a FEW degrees of retard. Using slightly rich mixtures (needle jet, idle jet and adjustment, and main jet), and modifying the ATU weights to have the F dot or Z line at the middle of the timing window at 3600 rpm; and the S mark centered or slightly below center.....all these things together....will usually fix the vast majority of pinging problems. If need-be, use premium gasoline. I usually get the advance range noted, by using the slightly stronger later springs, and lightening the advance weights some.

Be sure to check that the carburetors are tightly mounted, and that there are no vacuum leaks between the carburetors and the heads. Do this with the engine hot from riding. Let the engine idle, and spray brake cleaner at the interface between carburetors and cylinder heads. Absolutely no change in rpm should be heard when spraying. Spray around the throttle shaft and enrichener too if you have a CV carburetor. Any such vacuum leaks will cause various problems. Be sure the valves are set correctly. Valves and ignition timing (if has points, gap setting first) must always be set properly before doing any carburetor adjustments.

Be sure that the carburetor jetting and adjustments are correct, as a slightly lean mixture will ping much more easily. Note what I said previously about the carburetors running too lean, particularly with gas-o-hol (10% ethanol alcohol is now STANDARD in USA fuels).

If it still pings, and you are not doing something wrong, such as wrong or bad fuel, or, using a lot of throttle below ~3500 rpm; & if the ignition, plugs, wires, etc., are all OK ...then you may want to remove the heads and clean out the carbon and pay attention to any sharp places that carbon will gather at. Consider dual-plugging when heads are removed.

As an engine wears, the crankshaft timing chain sprocket wears, as does the cam sprocket, guide/tensioner, and chain. Such wear, which is normal, causes the valves camshaft to lag behind the crankshaft position, compared to the original design specifications. This means, that in regards to piston position, the intake valves open later. The camshaft timing, in actual effect, is lagging, and the valve timing is even more mild, promoting leanness, more heat, more pinging, less power, more use of throttle, etc.

Be sure not to idle the engine too slowly, as that reduces lubrication to the timing chest parts. I suggest the carburetors be carefully balanced and that the idle rpm be set no lower than 900 on heavy flywheel models. 1000 to 1100 is OK ...and better ...especially for 1981+ models, but also benefits earlier models.

Be sure the adjustment of the throttle cables is synchronized, this is always done after the idle adjustments. Do the cables at 1500 rpm. Carburetors that are well out of synch will tend to make pinging worse. All carburetor adjustments are done with a fully warmed-up engine from actually riding the bike at least 10 miles.

Even with most everything done, & properly, you may get an occasional ping under medium-hard acceleration, especially at lower rpm.

I suggest that too much throttle not be used below 3500; and, if you hear pinging, back off the throttle some.

There is a lot of information in https://bmwmotorcycletech.info/timingchain.htm. Try my hints, etc., in this article, before thinking about decarboning, dual-plugging or timing chain area repairs.

DECOKING (also called DECARBONING):

This is best done by removing the heads, cylinders, and pistons, for a full clean-up. This work requires resealing the cylinder, new head gasket, etc. Chevron Techron can help considerably, over some goodly miles. Using the concentrated Techron from the plastic bottle per bottle-printed instructions will work fairly well with two to three tanks of fuel; but, in the long run, it is cheaper, depending on one's total mileage over time, to just purchase Chevron's Techron-containing gasoline's. The standard Techron additive bottle is good for 3 tanks of gasoline (1/3 bottle per tankful). Even this Top Tier fuel or the Techron additive is not going to do a perfect carbon cleaning job of the head, valves, piston top and piston rings/lands area. But, continued use does work pretty well. Further information on removing carbon deposits is discussed in these two articles:

https://bmwmotorcycletech.info/break-in.htm

https://bmwmotorcycletech.info/chemicalsetc.htm

Some additional information; maybe some more nerdiness; whatever:

The flame propagation is greatly enhanced by turbulence in the fuel-air mixture. If a squish band is used, reducing its height is advantageous as it gives increased turbulence. Going below 0.635 mm of squish is to be done only with great care. Since the gaseous mixture in the squish band is usually NOT burned, squish bands tend to be engineered out, due to the increase in smog from the engine. A lot of technical information has been published about the squish area; and, I am going to avoid going deeper here.

Hot rodding technique usually includes enlarging and reshaping the intake ports to increase flow rate. Porting does not affect turbulence much, unless drastically done. Porting almost always DOES improve engine performance.

Mixing gasoline at the fuel pump (so much of one octane and so much of another octane) will NOT necessarily result in an octane value based on the mean figure between the two volumes.

The amount of useful power from lower octane versus higher octane, assuming the engine will function properly, is very small in difference. Energy per ounce, that sort of thing. This includes race-type gasoline. If anything, higher octane fuels tend to deliver poorer mileage.

Carburetors do not really atomize the fuel, rather, the fuel is introduced into the air flow as very tiny droplets, but still liquid.

© Copyright 2020, R. Fleischer

Return to Technical Articles LIST Page

Last check/edit: Sunday, December 06, 2020